Plant based cellulose nanofiber (CNF) material is attracting attention as a new material, and researchers are examining possible applications for reinforcing other materials. However, it is difficult to distribute the CNF in resin evenly, so research and development is focusing on methods to manufacture bicomponent filaments using CNF for strengthening, and technology to analyze its characteristics. A research group comprised of Professor Fumio Narita and Assistant Professor Hiroki Kurita of the Tohoku University Graduate School of Environmental Studies has successfully manufactured a bicomponent filament that combines CNF, defibered at the nano level, with silk, without the use of any special equipment. The material is expected to be useful in creating green composites that are gentle on the environment. Their results have been published in the journal Materials & Design.

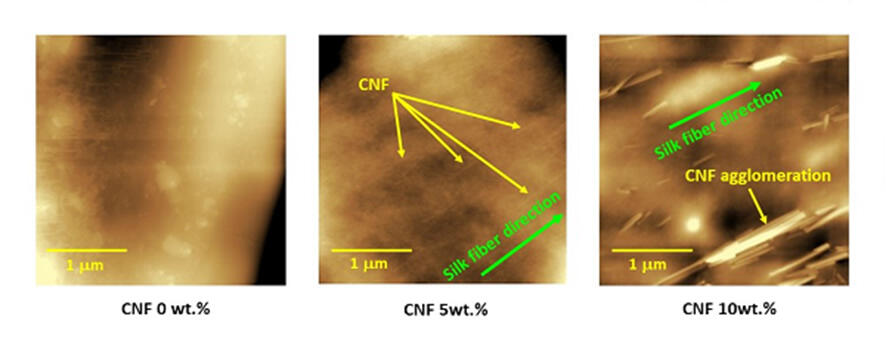

The silk threads they produced can be obtained easily by mixing CNF into the commercially available food of silkworms for them to consume. Another challenge has been that there is yet a technology to strengthen CNF made from plant-based nanofibers by arranging the orientation of the fibers, and the use of the silkworm, an herbivore, to do so is a new development. The team also used a scanning probe microscope with the cooperation of Shimadzu Corporation to observe the orientation and distribution of the CNF.

The methodology consisted of creating silkworm food containing 5% and 10% CNF by weight. Tension tests carried out on the silk taken from the cocoons of silkworms that consumed the 5% CNF food found that the modulus of longitudinal elasticity had more than doubled, and that both the tensile strength and specific strength had also increased. Furthermore, they confirmed that the CNF fibers were oriented in the same direction and found evidence that the addition of CNF to the silk threads improved their mechanical properties.

Silk is produced by a pair of silk glands found in the bodies of silkworms. Silk thread is comprised of 70% fibroin, a type of protein made of two porous fibers, and 30% sericin. The tensile test carried out by the team measured the modulus of longitudinal elasticity and tensile strength and achieved a positive outcome without separating the fibroin and sericin.

Because the group succeeded in creating a silk bicomponent filament in which the CNF orientation is aligned, there are expectations that the material can be combined with plant-based resin to create a green composite using aligned CNF. It is expected that the bicomponent filament can be mass produced by raising silkworms on CNF. This will expand the range of potential applications and also serve to invigorate the silk industry.

(Credit: ©Tohoku University, Shimadzu Corporation)

This article has been translated by JST with permission from The Science News Ltd.(https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.

This article has been translated by JST with permission from The Science News Ltd.(https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.