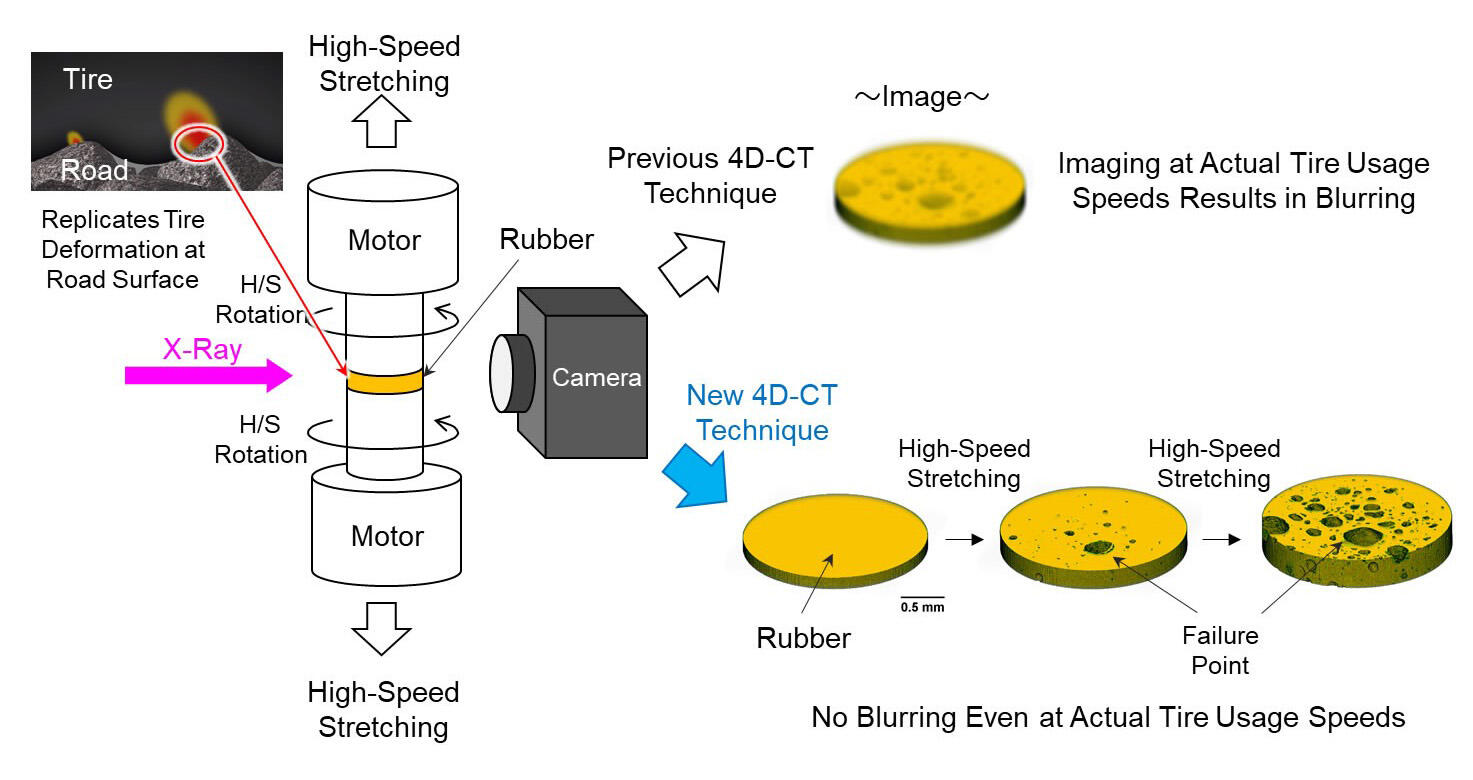

In a joint research project between industry and academia, a research group including Sumitomo Rubber Industries and Associate Professor Wataru Yashiro of the Institute of Multidisciplinary Research for Advanced Materials, Tohoku University, has improved their 4 dimensional x-ray CT (4D-CT) methodology developed using Spring-8, which is in turn based on Advanced 4D Nanodesign, a proprietary new materials development technology unveiled by Sumitomo Rubber in 2015, and by doing so, have accelerated image capture speed by approximately 1,000 times. The group succeeded in making 4D observations of the actual failure of the rubber in tires, at a range of speeds, for the first time in the world.

4D space-time (three dimensions of space and one of time) in the millisecond order encompasses a vast range of knowledge that is inaccessible to even cutting-edge measurement technology. According to Yashiro, "In order to achieve micro x-ray CT scans with a time resolution in the order of milliseconds, you must use an extremely strong source of synchrotron radiation and spin the sample at an extremely high speed (of thousands to tens of thousands of rpm)."

The research group has been working on developing high speed 4D-CT technology to solve the issue. Considering that the area which can be captured to produce a single 3D image is tiny at only 5 mm square, making it difficult to capture material failure, they enabled image capture at approximately 1,000 times the speed, or under roughly 0.01 seconds. By doing so, they were able to capture the process of rubber failure, close to the point when tires wear out, in 4D both continuously and at a variety of speeds.

If the synchrotron radiation facility currently under construction in Sendai City, Miyagi Prefecture is utilized, it is theoretically possible to capture micro x-ray CT images at a time resolution higher than a millisecond. However, there are several problems incurred involving controlling the environment around the sample. For example, samples can warp due to centrifugal force when spun at high speeds, while fluid samples cannot be used at all.

The research group's achievement was realized through the combination of Sumitomo Rubber's abundant knowledge of rubber and the world's fastest x-ray CT technology possessed by the Institute of Multidisciplinary Research for Advanced Materials at Tohoku University.

According to Yashiro, "We have succeeded in capturing millisecond x-ray CT images without spinning the sample by using multibeam synchrotron radiation as part of the JST/CREST Project. We will further improve the technology moving forward and not only use it to understand a variety of non-reversible and non-equilibrium system in the physical and life sciences, but we also hope to contribute to general society, such as by developing materials for a sustainable society."

This article has been translated by JST with permission from The Science News Ltd.(https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.