A research group comprised of Professors Yoji Mine and Kazuki Takashima of the Faculty of Advanced Science and Technology, Kumamoto University, has successfully achieved precise measurements of the mechanical properties (tensile strength and ductility) of crystalline phases found in iron meteorites that are finer than a strand of hair, for the first time in the world, using a proprietary micro tensile testing technology they developed.

(Credit: Kumamoto University)

Previously, cracks and cavities in iron meteorites had interfered with the measurement of the true tensile strength and ductility of the component phases. By applying their micro tensile testing technology, they were able to collect test specimens while avoiding those defects, enabling them to measure the mechanical properties of each component phase.

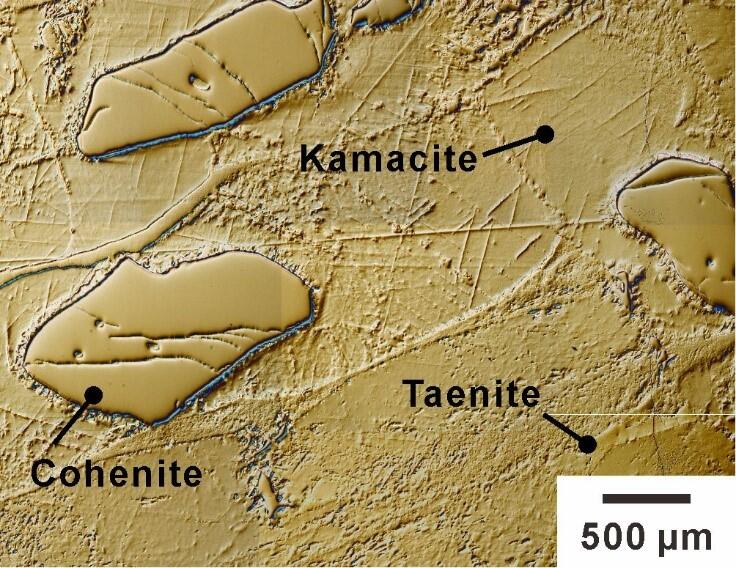

Iron meteorites are comprised of alloys of iron and nickel. The most common structures found in the meteorites are kamacite, a body-centered cubic crystal structure, taenite, a face-centered cubic crystal structure, and cohenite, an orthorhombic crystal structure. The sample used for this research was a Canyon Diablo meteorite. The group measured the yield strength of the kamacite at which plastic deformation begins, and the ductility before breaking, finding values of 350 MPa and 19% respectively. The values found for taenite were 935 MPa and 65%.

Normally, large amounts of nitrogen cannot be included in the various nickel containing steel materials made on Earth, but it was found that the taenite in the iron meteorites contains a high percent of nitrogen (1.35% mass) that contributes to the mechanism by which it achieves high strength and ductility.

According to Mine, "A major challenge for the development of modern high tensile steel is the development of high tensile austenite that can compensate for the risk of hydrogen brittleness under severe environmental conditions. We hope that the discoveries in our research will be helpful for the development of advanced high tensile steel, and serve as motivation for research to understand the relationship between nitrogen and nickel content in steel."

This article has been translated by JST with permission from The Science News Ltd.(https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.