A research group led by Senior Researchers Yuya Sato, Tomoyuki Hori and research group leader Hiroshi Habe of the Environmental Management Research Institute, National Institute of Advanced Industrial Science and Technology (AIST), has collaborated with manager Teruhiko Miwa and researcher Takuto Akachi, IAI Corporation, Professor Hiroyuki Futamata, Shizuoka University, Senior Researcher Keita Murofushi, Industrial Research Institute of Shizuoka Prefecture, and Principal Researcher Hiroshi Takagi, Numazu Technical Support Center, on the successful development of technology to consistently and efficiently produce organic liquid fertilizer for use in hydroponic farms. The fertilizer feedstock is wastewater from food processing, which contains high levels of protein.

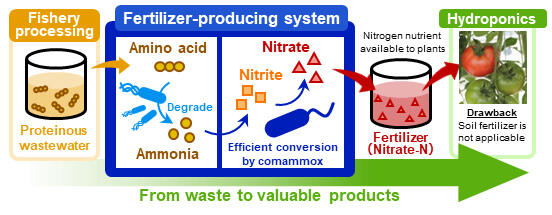

(Wastewater discharged from fish processing plants is rich in protein. In this system, amino acids, produced by the decomposition of proteins, are degraded to ammonia; this reaction can be carried out by a variety of microorganisms. In contrast, only a few microorganisms can perform the conversion of ammonia to nitrate via nitrite (i.e., nitrification). Notably, comammox, a unique bacteria discovered recently, efficiently converts ammonia to nitrate in this system. The high-quality nitrate solution produced can be used as a fertilizer for hydroponic cultivation of tomatoes and other crops.)

Organic farming that eschews the use of chemical fertilizers is gathering much public attention. However, few organic fertilizers for hydroponic farms have been developed. The reason is the difficulty of producing organic nitrate-nitrogen that can be used on plants without using scientific methods. IAI already produces eco-friendly nitrate-nitrogen organic liquid fertilizer from food processing wastewater using microbes as a raw material, but no stable maintenance method has been established due to the lack of knowledge about the state of microbes inside the liquid fertilizer production apparatus.

The research group therefore ran IAI's liquid fertilizer production apparatus for a period totaling more than one year. They found it could continuously produce over 100 liters of stable, highly concentrated liquid fertilizer per day. In addition, in the first 70 days of running the equipment, the team analyzed the microbial communities within two reactors and found that each had formed separate flora. Moreover, the search for key microbes within the apparatus revealed that the microbe known as Comammox, a unique, recently discovered microbe, was efficiently producing nitrate-nitrogen.

Sato explains that, "We have expanded the scale of the trial with liquid fertilizer production equipment (about seven times larger) and confirmed that the fertilizer we make is able to hydroponically grow consistent tomatoes. In future, I hope to proceed with analyzing the properties of this liquid fertilizer."

This article has been translated by JST with permission from The Science News Ltd.(https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.