Researchers Shun-ichi Funano (member at the time of research), Nobutoshi Ota, and Yo Tanaka (team leader) of the Integrated Biodevices Research Team at the RIKEN Center for Biosystems Dynamics Research have developed adhesive glass substrates that can be repeatedly attached and detached by cleaning their surface with a neutral detergent and applying pressure with a binder clip. They succeeded in producing a microfluidic device that can collect compartmentalized cells using these substrates. Manufacturing glass-based microfluidic devices typically involves the use of chemicals for cleaning and high-temperature heat treatments to induce bonding. In addition to this, removing glass substrates for reuse after they have undergone bonding is normally extremely difficult. Therefore, the research team investigated the feasibility of fabricating reusable microfluidic chips suitable for conducting accurate, high-speed analyses of cells and biological samples within extremely fine microchannels on a palm-sized glass substrate. Adhesives cannot be used owing to their fine structure, and the synthesis of current microfluidic chips involves high-temperature (≥ 400 °C) fusion.

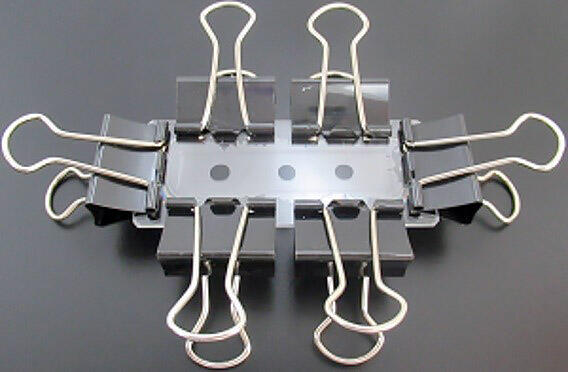

In the developed method, the glass substrates are washed with a neutral detergent, clamped together using a binder clip, and removed using a razor blade. The entire process can be conducted at room temperature. Broadly speaking, the chemical state of the glass surface can be divided into SiOH and SiO (Two silicon based chemical groups found in glass). In general, the greater the amount of SiOH relative to SiO (i.e., the higher the SiOH/SiO ratio), the stronger the adhesion between the glass substrates.

The study showed that glass surfaces washed with water alone showed the highest SiOH/SiO ratio (0.74), and the uncleaned glass surfaces showed the lowest ratio (0.38). When washed with a neutral detergent, the ratio was 0.66, suggesting that the chemical substances in the detergent inhibit hydration. In addition, evaluating the adhesive state revealed that the neutral detergent-washed substrates achieved successful adhesion over 98.1% of the substrate area (compared to 90.8% when washing with water alone). This confirmed that the developed method is effective at removing substances adsorbed on the glass surface. Furthermore, when the pressure resistance performance of the manufactured microfluidic device was verified, the pressure resistance reached almost 600 kPa upon washing the device with a neutral detergent and clamping it with a binder clip at room temperature for 6h. This pressure resistance is equivalent to that achieved using conventional methods. According to team leader Tanaka, "Our objective was to develop a simple method for reversible chemical-based surface adhesion. As glass substrates with smooth surfaces can be bonded to each other, our method can be employed for various industrial applications that require bonding and repairing glassware and fine-structured devices."

This article has been translated by JST with permission from The Science News Ltd.(https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.