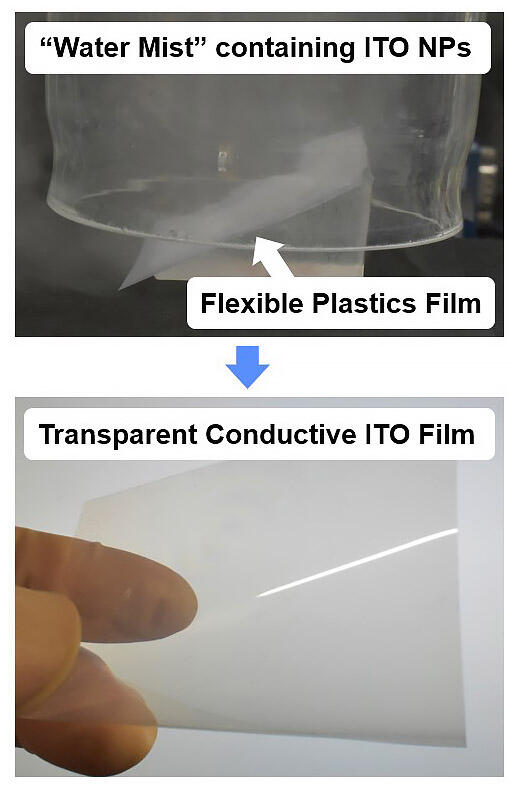

Professor Kiyoshi Kanie of the Institute of Multidiscipline Research for Advanced Materials, Tohoku University and Nikon's research group have independently developed indium tin oxide (ITO) nanoparticles that can be stably dispersed in water. They succeeded in manufacturing a transparent conductive thin film by mist deposition, which is a film formation method with low environmental impact.

Printable electronics comprises methods to manufacture the components of electronic devices, typically manufactured by the vacuum plasma process, via a process using ink as a raw material. Since it is difficult to form an ITO film at a low temperature in an atmospheric environment, the development and use of Ag nanowires as an alternative material are being considered. It is, however, expensive to use Ag nanowires because of the requirement of noble metals and deterioration due to electromigration, which have posed challenges to their development. According to Dr. Kanie, "The transparent and electrically conductive ITO thin film is a key material for display devices such as televisions and smartphones, but an environmentally friendly manufacturing process is required." In response to these challenges the research group developed a mist deposition method, in which a mist containing ITO nanoparticles is applied to the film under normal temperature and pressure.

In mist deposition, it is necessary to develop ITO nanoparticles that disperse stably in water. The research group confirmed that the hydrophilicity of the particles can be improved by preparing the ITO nanoparticles in a spiky, protruding shape. Such particles were observed to disperse stably for a long time compared to conventional products. In addition to this, in the coating solution where ITO nanoparticles are used as a raw material, it is not necessary to use an additive, which would require high-temperature treatment with an organic solvent or a surfactant or a high resistivity. As a result, it has become possible to produce aqueous inks. This means that solvent or surfactant removal at high temperatures (as required by conventional particles) is unnecessary, allowing for low-resistance transparent conductive membranes to be obtained at low temperatures (below 150 °C) and atmospheric pressure; further, resin films in conventional use can be employed as substrates. Combined with mist deposition, it was possible to obtain a membrane with a specific resistance of 9.0 × 10-3 Ω cm on polyethylene naphthalate (PEN) substrates at 150 °C.

Credit: Tohoku University, Nikon

- Prof. Kanie noted: "Mist deposition is much less environmentally harmful than conventional sputtering and ink coating, and significantly contributes to achieving carbon neutrality. When applied to other nanoparticles, this method can be expected to become a new manufacturing method for various highly functional thin films."

- ITO nanoparticles are nanosized particles that can be formed into ITO thin films using ink, without the need for expensive vacuum equipment. The developed films can be used in the same manner as typical ITO thin films, such as those used in transparent electrodes and heat reflection.

- Membrane formation is a gas-liquid mixing process, in which mist-like raw materials are transported through gas by spraying ultrasonic waves of several megahertz in a raw material solution.

This article has been translated by JST with permission from The Science News Ltd.(https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.