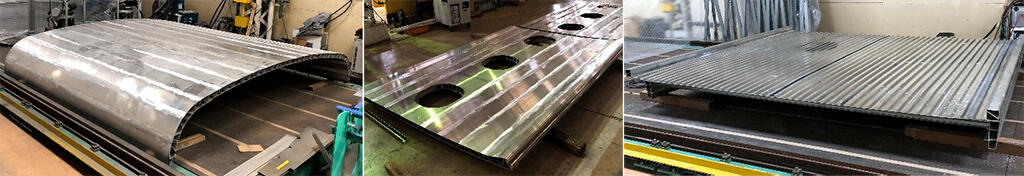

Under the "Research and Development of Innovative Structural Materials" project promoted by the New Energy and Industrial Technology Development Organization (NEDO), the Innovative Structural Materials Association (ISMA) created a large partial structure with a height of 2.9 m, width of 3.4 m, and length 5.0 m. This structure was used to simulate the parts of the cabin where loads are repeatedly applied when a Shinkansen train enters and exits a tunnel. A total of 147,000 airtight fatigue tests were performed; these are equivalent to 20 years of tunnel entry and exit, i.e., the design life of the vehicle. The results confirmed that the partial structure using a flame-retardant magnesium alloy could withstand long-term operation.

Credit: NEDO

The partial structure is made of a magnesium alloy with improved flame retardancy, and its specific gravity is at least 30% lower than that of lightweight aluminum. This means that both a significant weight reduction and high reliability of the vehicle can be achieved.

In the future, they aim to cultivate the market and apply the flame-retardant magnesium alloy to structures with a total length of 20 to 25 m for next-generation Shinkansen trains by extending the application of flame-retardant magnesium alloys to passenger interior materials and equipment covers of railway vehicles.

Currently, a lightweight aluminum alloy is generally used to construct the vehicle structure of high-speed railways, such as the Shinkansen. However, with the increasing importance of speeding up transportation and saving energy, the need for further weight reduction has increased in recent years.

Magnesium, which has a specific gravity that is at least 30% lower than that of aluminum, has attracted attention for achieving weight reduction. Early commercialization of large structures using magnesium alloys is expected not only in railways but also in the fields of automobiles and space/aviation. However, materials made of magnesium alloy have a relatively low flame retardancy, corrosion resistance, and moldability. Therefore, the material is mostly used for small parts, such as electronic housings and machine parts, and there are few examples of its application in large structures.

To this end, NEDO has been working on the "Research and Development of Innovative Structural Materials" project since FY2014. Under this project, ISMA has developed a flame-retardant magnesium alloy with improved strength, ductility, and processability for application to high-speed vehicles, which tend to be large structures. As a result, in 2016, they succeeded in prototyping a panel for the side structure of a vehicle using the flame-retardant magnesium alloy. By 2018, they succeeded in prototyping a partial structure (height 2.9 m × width 3.4 m × length 1.0 m) of a high-speed rail car whose cross section is of the same size as the current Shinkansen train, demonstrating that a large structure using magnesium alloys can be manufactured. Here, to check the fatigue strength against repeated loads when entering and exiting the Shinkansen tunnel, a larger partial structure was constructed, and an airtight fatigue test equivalent to tunnel entry and exit considering a design life of 20 years was conducted. Consequently, it was confirmed that the partial structure using the flame-retardant magnesium alloy could withstand long-term operation.

This article has been translated by JST with permission from The Science News Ltd.(https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.