A study group led by Associate Professor Akihiro Takezawa of the Faculty of Science and Engineering, Waseda University announced that they have developed a technique to reduce the thermal distortion of metal 3D printing. The deformation of the product modeled in the experiment was successfully reduced by optimally designing and forming the lattice structure (hollow structure) inside. The especially large deformation seen during the molding of large structures is expected to be reduced using this new method. The groups' findings were published in the November 6 issue of the international scientific journal "Additive Manufacturing".

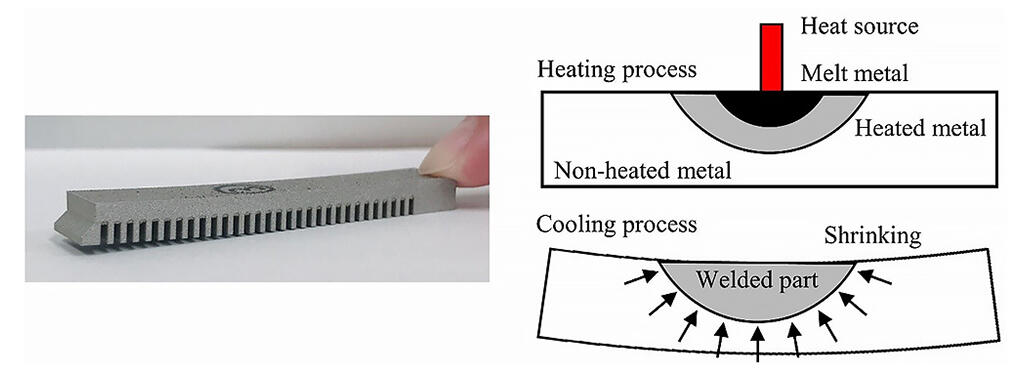

There have been recent advances in the use of metal 3D printing as a next-generation processing technique. In the most popular type of metal 3D printing, the three-dimensional structure is formed by repeating the process of melting and solidifying a thin layer of metal powder with a laser. However, a large shrinkage strain is generated in the melt-solidified portion when subjected to cooling.

When the modeled object is separated from the base at the time of fabrication, the strain causes a large warpage, which causes defective products. To mitigate this issue pre-heating of the fabrication bed to reduce the temperature difference between the melting and cooling phases, and scanning with a short beam pass were effective.

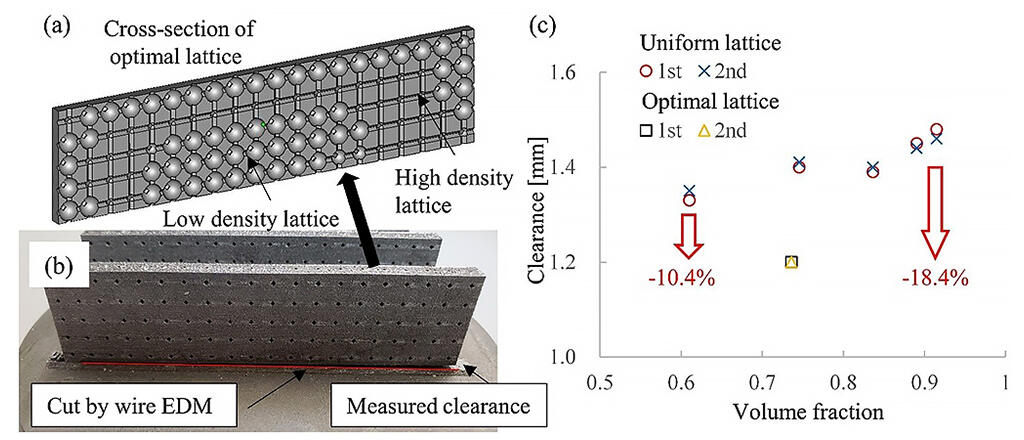

With the aim of further reducing thermal distortion, the research group has developed a method for designing a hollow structure called a lattice structure inside a metal-3D-printed object. It was experimentally confirmed that the thermal distortion could be reduced by fabricating the modeled object and arranging the lattice structure optimally. In general terms, simply designing a hollow structure inside the object will disperse tension and reduce the thermal distortion. When an object with a uniformly distributed lattice structure and one with an optimally distributed lattice structure produced by the developed method were compared, the amount of warpage could be reduced by 10% or more in optimally dispersed model.

In the development of this method, the inherent strain method expressed by a simple recursive formula that approximates welding deformation was used. Furthermore, by utilizing the algorithm of topology optimization, which is a method of structural optimization, the researchers have succeeded in developing a technique for optimally determining the coarse and dense distribution of lattice structure to reduce thermal distortion.

In this method of 3D metal printing, a hollow spherical lattice structure is formed inside the modeled object. In this study, a spherical lattice structure was formed, but its shape differs depending on compatibility with the 3D metal printing equipment. The modeled objects can have sparse lattice regions where several lattice structures are distributed and dense lattice regions where there are no lattice structures. A lattice-shaped hollow structure connected to the lattice structure is also formed inside the modeled object, which is used to remove metal powder when fabricating the hollow structure.

An even better thermal distortion reduction effect can be expected by using this method together with existing reduction techniques. Associate Professor Takezawa commented, "We are currently studying the optimization of the scanning path of the laser, which is an existing technology. We believe that using this in conjunction with the newly developed technology will further improve thermal distortion."

This article has been translated by JST with permission from The Science News Ltd.(https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.