The research group composed of Research Fellow Tomoki Iwama, Assistant Professor Yuanyuan Guo, Associate Professor Kumi Inoue, and others of the Center of Innovation (COI), Tohoku University, succeeded for the first time in the world in the mass production of "bipolar electrochemical microscopy (BEM)" electrode elements by a thermal drawing method in which heat and tension are applied to a thermoplastic material to mass-produce fibers with an arbitrary cross-sectional design. Furthermore, the group succeeded in manufacturing a tapered BEM electrode element with a concave tip by the same method and succeeded in demonstrating the principle of magnified imaging that visualizes a small area as a greatly magnified optical image.

Microscopic technology that visualizes biomolecules makes it possible to understand biological phenomena and contributes to the elucidation of disease mechanisms and the development of therapeutic methods. BEM, which has been developed in recent years, can visualize the molecular concentration distribution with a high resolution by using a high-density electrode substrate and optical signals. However, a method for the stable mass production of electrode substrates for microscopes had not been established, and this has become a bottleneck for basic research and practical application.

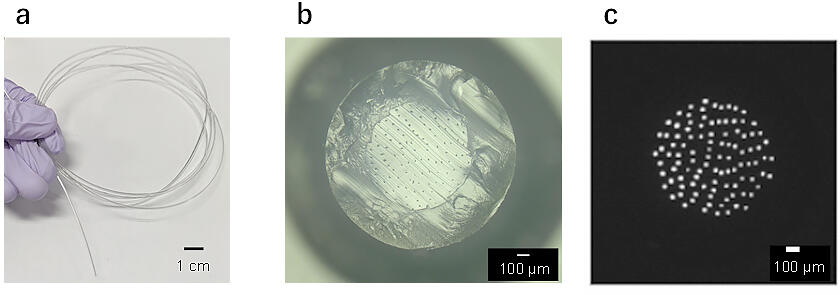

The research group aimed to establish a mass production method for BEM electrode elements that would accelerate the research and development of BEM and put it into practical use. Therefore, the research group focused on a thermal drawing method that can be performed by applying heat and tension to a thermoplastic material and stretching an electrode fiber with an arbitrary cross-sectional design. By stretching a mold containing 104 carbon electrode materials inside, a fiber-shaped BEM electrode element could be fabricated. This is the same principle as that used for making Kintaro-ame (a candy made by stretching). The fibers that can be produced at one time are several hundred meters long, and it is possible to recover more than 20,000 BEM electrode elements by cutting at any point. Furthermore, by heat-stretching the manufactured electrode element again, a tapered BEM electrode elementwith a tapered tip could be manufactured, which was unprecedented worldwide.

Provided by Tohoku University

As a result of this, the group succeeded in demonstrating the principle of magnified imaging (magnification factor 4.7 times) for observing the molecular concentration of a small area at the squeezed tip as a greatly magnified luminescence image. Associate Professor Inoue stated, "A technology for visualizing the dynamics of biomolecules is required in a wide range of fields, such as life science, medicine, and pharmacy. Using the thermal stretching method, we could produce fibers containing approximately 100 carbon electrodes, and we could demonstrate a method for the mass production of BEM electrode substrates. In the future, it is expected that BEM will become widespread as a powerful biomolecular imaging technology that accelerates life science research by increasing the density of electrodes."

This article has been translated by JST with permission from The Science News Ltd.(https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.