The collaborative research team composed of the RIKEN Center for Advanced Photonics Neutron Beam Technology Team Research Scientist Kunihiro Fujita and Team Leader Yoshie Otake, and the Principal Researcher Hiroyuki Noda of JFE Engineering Technology Headquarters Research Institute has developed a system for non-destructive imaging and quantitative evaluation of the deterioration of reinforced concrete decks under asphalt pavements. Because neutron scattering can be used to non-destructively inspect aging concrete structures such as bridges and tunnels, it is expected to lead to better social infrastructure longevity and the prevention of accidents. Fujita said, "This technology will be an effective means of addressing aging infrastructure, which has become a social issue. We want to be able to apply it outdoors to an actual site in around three and a half to four years."

The floor slab under the asphalt of a road bridge is an important aspect that supports the load of cars and people. If the concrete inside deteriorates and becomes sediment, a serious accident may occur; therefore, it must be inspected regularly. The trigger for sedimentation is the intrusion of water and the accompanying creation of space in the material. However, with current visual inspections, the asphalt must be removed after each inspection.

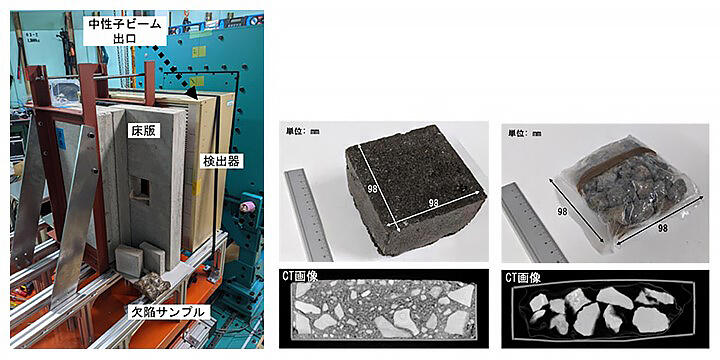

With these developments, the joint research team used the developed neutron imaging device and RIKEN accelerator-driven compact neutron source RANS II to perform non-destructive measurement of concrete decks with simulated internal deterioration. As a result, the team succeeded in visualizing sedimentation (moisture/voids (a gap caused by air)), quantitatively evaluating the size of the deteriorated part, and separating and identifying deterioration containing both moisture and. In particular, the neutron yield distribution was measured in the healthy state and defective state of the concrete, and the ratio was taken to quantitatively evaluate the type and volume of the defect.

Provided by RIKEN

Team Leader Otake said, "When using this technology in the field, it is possible to evaluate defects based on the most deteriorated part of the structure with the assumption of various construction methods and the passage of time." To determine whether the defect is moisture, a void, or both, the team focused on the time difference between the neutrons propagating inside the concrete (the velocity differs depending on the concrete, moisture, and space) and established a data analysis method using time information from neutron generation to detection. The proton beam generated from the RANS II accelerator is guided to the lithium target, where a neutron beam is generated by a nuclear reaction. The deck was irradiated by a fast neutron beam with an intensity of approximately 104 cm2/s and a diameter of 40 mm. Irradiation was conducted with this fast neutron beam for five minutes per sample setting.

Measurements were performed for neutrons scattered by the position-sensitive helium-3 proportional counter of the detector. By analyzing the results, it was found that the amount of water and the size of the gap can be quantitatively evaluated. The research team is currently developing a small accelerator, RANS III, that can be mounted on a trailer and aims to put it into practical use in an actual site by repeating demonstration experiments and obtaining permission from regulatory authorities.

This article has been translated by JST with permission from The Science News Ltd.(https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.