To reduce carbon dioxide emissions, which is a global issue, light-weight automotive bodies have attracted attention for improving the fuel efficiency of automobiles and other transportation equipment. In recent years, the use of adhesives has attracted attention as an alternative technology for joining dissimilar materials owing to their high productivity and cost-effectiveness. However, since these technologies are planned to be used in transportation equipment and can thus significantly jeopardize human life, investigating their reliability and durability has proven challenging.

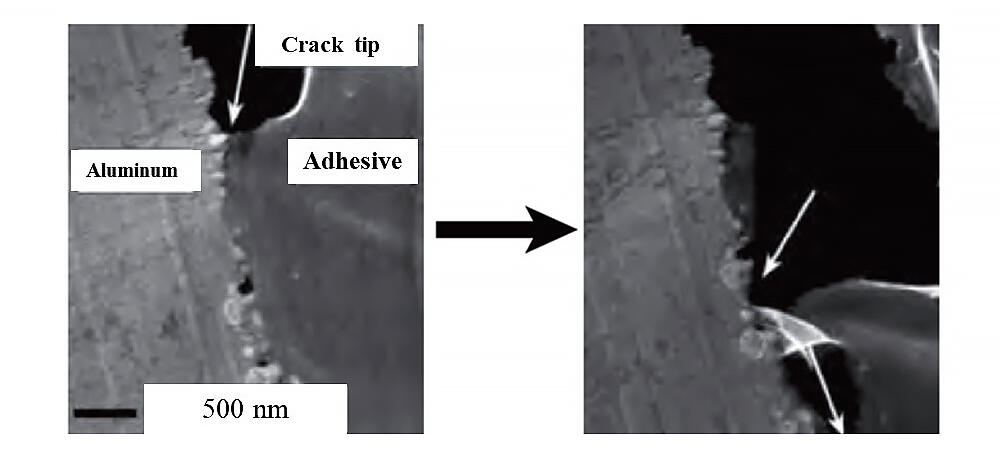

For the first time, using a transmission electron microscope (TEM), which can detect even minute deformations, a joint research group led by Shin Horiuchi, Chief Senior Researcher at Nanomaterials Research Institute, National Institute of Advanced Industrial Science and Technology, succeeded in the real-time observation of the breakage in adhesive joints at the nanometer level. Specifically, a 100-nm thick sample of adhesive-bonded aluminum alloy, which is sufficient for the electron beam to pass through, is cut and formed. Then, both ends of the sample are pulled slightly to create a small strain inside the adhesive. Researchers used TEM to observe a series of processes, wherein the strain evolved into cracks, reached the adhesive/metal interface, and resulted in fracture. To observe the origin of fracture in adhesive bonding through TEM, the joint research group is proceeding with detailed analysis and aims to clarify the complex mechanisms of adhesive fracture in the future. Based on these findings, the researchers plan to develop durable adhesives, optimize surface treatments for adherends, and evaluate and demonstrate reliable adhesive joints.