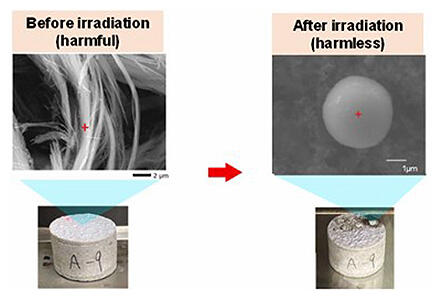

NTT has confirmed that the shape of asbestos can be transformed from a fiber to a sphere through irradiation with a high-power laser. Furthermore, using a diffractive optical element (DOE), they have developed a laser irradiation technology to suppress the scattering of asbestos dust.

During work that involves the removal of building materials containing asbestos, there is a risk of inhaling harmful asbestos dust, which can cause diseases such as lung cancer and malignant mesothelioma in workers. NTT have said that they transformed asbestos into a harmless spherical shape using the developed technology, and at the same time, made it possible to significantly reduce the health risk of workers due to the amount of scattered dust that could be suppressed. The content of this technology was reported at the International Society for Optics and Photonics (SPIE) Photonics West On-demand, which was held from February 21st to 27th.

Provided by NTT

Asbestos has been widely used as a heat-insulating material in buildings, etc.; however, it has become apparent that when inhaled by humans, asbestos can cause lung cancer and malignant mesothelioma. As a result, asbestos is currently banned in many countries. It is believed that asbestos is harmful due to its extremely thin and pointed shape. Furthermore, when inhaled by the human body, it can be easily deposited in the alveoli, resulting in possible long-term lung tissue damage. This can lead to genetic abnormalities and cause cells to become cancerous. When removing asbestos during the demolition of an old building, asbestos removal tools, such as power tools, can scatter harmful dust around. Thus, workers and the area around the work site need to be protected from exposure to asbestos dust.

Therefore, to fundamentally avoid such exposure risk, there is a demand for asbestos removal technology that can detoxify harmful dust. The high-power laser used by NTT for development was expected to heat-melt asbestos at the irradiation point and change its shape. The laser irradiation experiment conducted by NTT confirmed, for the first time in the world, that the shape of asbestos changed. In this experiment, as a result of melting the asbestos by using a laser contained in the building material, the harmful fiber shape of the asbestos changed into a harmless spherical shape. Furthermore, by using a DOE to control the power density and beam shape of the high-power laser that irradiates the asbestos-containing coating material, the company also succeeded in suppressing the amount of dust during laser irradiation.

Provided by NTT

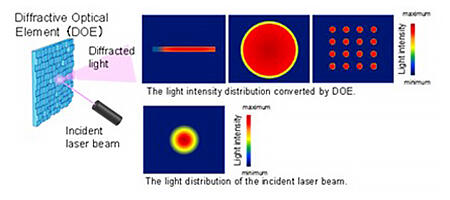

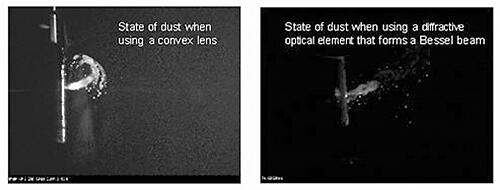

The DOE is a device that can freely change the shape of the laser beam by utilizing the diffraction phenomenon of light. By using this DOE, the laser light is formed into a Bessel beam (a non-diffraction beam that does not spread due to the diffraction phenomenon), reducing the risk of exposure by significantly reducing the amount of dust scattered during laser irradiation. NTT has realized a DOE that is compatible with 10 kW class high-power lasers with low-cost silicon. Additionally, it will be possible to reduce the cost of the laser irradiation device for asbestos detoxification in the future. Furthermore, a lighter and smaller version of the laser irradiation part (laser head) can be manufactured by using the DOE.

Provided by NTT

This article has been translated by JST with permission from The Science News Ltd.(https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.