A research group consisting of Senior Researcher Dai Kutsuzawa, Senior Researcher Takeshi Kobayashi, and Senior Researcher Seiki Komiya of the Energy Transformation Research Laboratory of the Central Research Institute of Electric Power Industry (CRIEPI) has successfully developed a technology for fabricating all-oxide solid-state batteries at lower temperatures than previously possible.

Credit: CRIEPI

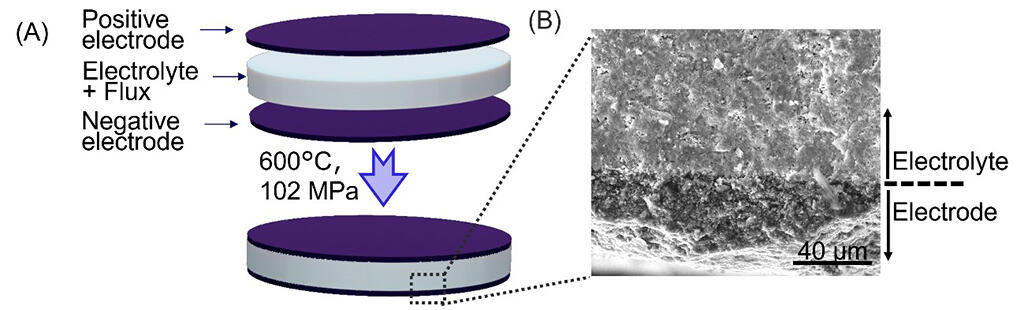

The research group fabricated a symmetric oxide solid-state sodium battery consisting of a solid electrolyte layer of Na3.1Zr1.95Mg0.05(SiO4)2(PO4), a NASICON-type oxide, sandwiched by an electrode layer consisting of Na3V2 (PO4)3 active material, also a NASICON-type oxide. By mixing Na2B4O7・10H2O, which melts at low temperatures, into the solid electrolyte layer in advance as a sintering aid, they were able to fabricate an all-solid-state oxide battery at 600°C, a lower temperature than previously possible. Cross-sectional observation of the fabricated battery showed that the electrolyte layer was sintered with few gaps and the electrode layer was tightly bonded to the electrolyte layer in spite of the low temperature fabrication.

Next, they examined the charge-discharge performance of the fabricated all-solid-state battery and obtained a discharge capacity of 78 mAh/g (approximately 66% of the theoretical capacity) in the first discharge. After 99 cycles, the discharge capacity remained approximately the same value, and they confirmed the coulombic efficiency to be nearly 100%. This is the lowest degradation compared to all-solid-state oxide sodium batteries reported to date, indicating that the low-temperature fabrication method may also lead to favorable battery characteristics.

"This research result came about in the course of experimenting with various glassy materials," says Dr. Kutsuzawa. "Moving forward, our first goal is to further lower the fabrication temperature. We want to reduce the temperature by another few hundred degrees as the fabrication temperature has a significant impact on cost and CO2 emissions during manufacturing. In addition, we aim to extend the life of the battery to a level that will enable it to withstand operation for 20 years, with a view to using it as a storage battery for power."

■ NASICON: Abbreviation for "Na superionic conductor," a generic name for a group of materials with structures similar to Na1+xZr2(SiO4)x(PO4)3- that exhibit excellent Na ion conductivity. The NASICON-type oxides, which exhibit the best Na ion conductivity, have conductivities in the 1 mS/cm range at room temperature.

■ Active material: A material in which electrical energy and chemical energy are mutually exchanged by charging and discharging (oxidation-reduction reaction).

This article has been translated by JST with permission from The Science News Ltd.(https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.