On July 12, a research group at Toshiba Corporation's Mechanical Systems Laboratory, part of the company's Corporate Research & Development Center, announced that it had conducted a demonstration test with the Fukuoka-Kitakyushu Expressway Public Corporation to demonstrate the performance of technologies for analyzing and visualizing the internal soundness of bridge decks, which cannot be confirmed externally. By applying methods used in seismic source surveys, weak waves generated on the road surface when a vehicle travels over a bridge are acquired and analyzed by sensors installed on the undersurface of the deck. Degrees of internal damage that cannot be visually confirmed are visualized and presented as a soundness map. The company aims to make this technique into a service available from FY2024 and will continue to conduct demonstration tests. It is hoped that this technique will help extend the life of societal infrastructure.

Courtesy of Toshiba Corporation

Courtesy of Toshiba Corporation

Much of Japan's infrastructure was built during the period of rapid economic growth. As a result, according to the Ministry of Land, Infrastructure, Transport and Tourism, 63% of bridges will be 50 years old in 2033. Rebuilding so much infrastructure at once is difficult, especially due to Japan's declining labor force. These circumstances mean a shift to preventive maintenance is required, rather than just repairing accidents after they occur.

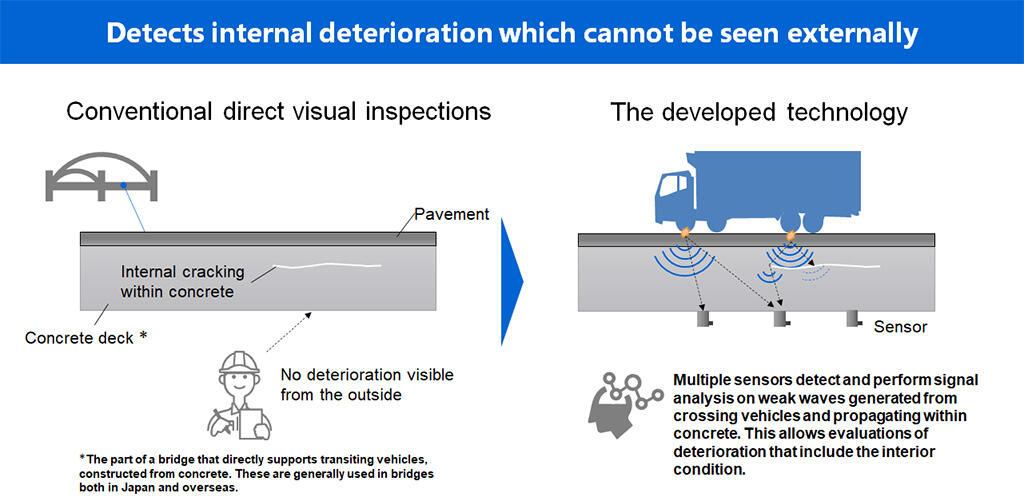

The Road Act was revised in 2014 in response to the ceiling of the Sasago Tunnel collapsing in 2012. Since then, bridges and tunnels must undergo a visual inspection every five years. However, internal cracks in concrete structures cannot be visually identified.

The group developed a technology to visualize deformations inside bridge decks using sensing technologies to address this issue. By installing multiple acoustic emission (AE) sensors under the deck, the sensors can detect elastic waves from vehicles driving on the asphalt and analyze the distribution of the seismic source to visualize the degree of soundness. If there are internal deformations, the wave propagation is attenuated by features such as cracks, enabling areas with deformations to be identified.

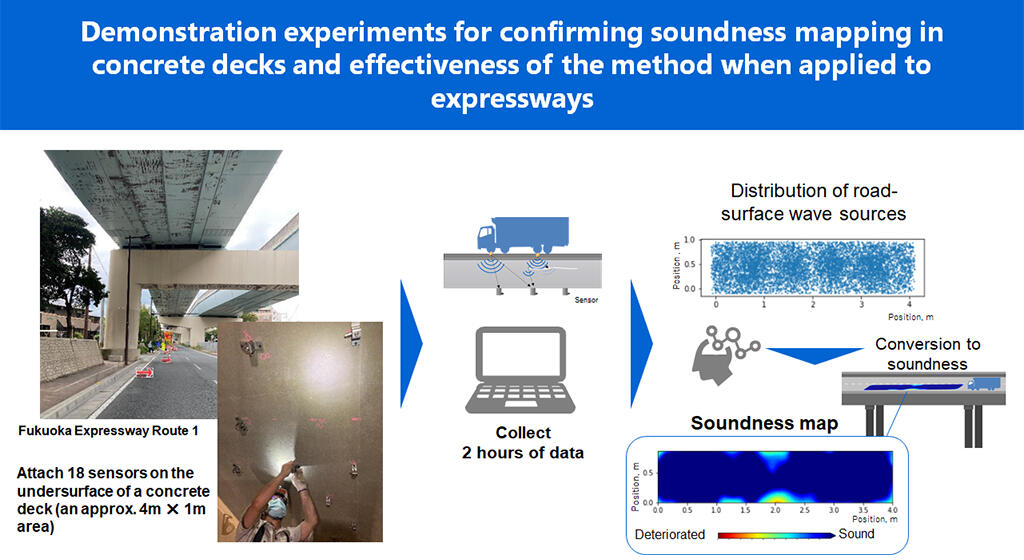

The soundness map indicates the degree of damage with colors ranging from red (damaged) to blue (undamaged). Although the map cannot determine features such as crack depth, the degree of deformation will be displayed if there are any deformations in the direction of the crack's depth. The company used its proprietary signal processing technologies for noise elimination.

Demonstration experiments were conducted between 2021 and 2022. Researchers began by installing 18 sensors on the underside of the concrete deck (approximately 4 m x 1 m) of Fukuoka Expressway No. 1. Signals were then continuously measured for two hours. Data analysis showed that the deck was generally sound, with slight damage.

To evaluate the validity of the measurement, four holes of approximately 10 mm in diameter were drilled from the underside of the deck at four locations in the measurement area (three locations detected as sound and one as slightly damaged), and the holes were examined. 0.2 mm cracks were discovered in the areas indicated on the soundness map as slightly damaged (yellow).

To verify whether the technology could be used to evaluate the effectiveness of a repair quantitatively, a second demonstration test was conducted on Fukuoka Expressway Route 2, which required repairs. The same procedure was used to measure the aged deck, with many areas displayed in red on the soundness map before the repair. After repairs were made using resin injections, the measurement was performed again. Researchers confirmed that the soundness map showed that all surfaces had their soundness restored, being displayed in blue.

Toshiba Plant Systems & Services Corporation plans to provide this service to road operators in 2024. The company will conduct future verification tests, aiming to use the system not only on bridges but also on various other types of concrete structures, evaluating soundness through detecting internal cracks and other problems.

■ This newly developed technology includes results from the "Robot and Sensor System Development Project for Infrastructure Maintenance and Disaster Surveys," a research project commissioned by the New Energy and Industrial Technology Development Organization (NEDO).

This article has been translated by JST with permission from The Science News Ltd.(https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.