Junichiro Kamiya, principal researcher at the J-PARC Center of the Japan Atomic Energy Agency (JAEA), and Nariaki Okubo, principal investigator at the JAEA Nuclear Science and Engineering Research Center, announced that they have developed a technology to use a titanium vacuum vessel as an ultra-high vacuum pump that does not require a power source. Focusing on titanium's ability to adhere or absorb gases (getter performance), the vacuum vessel itself is used as an ultra-high vacuum pump by modifying the surface of the titanium vacuum vessel. When the prototype getter pump was attached to an electron microscope, the researchers confirmed that the vacuum performance was improved by one order of magnitude. This achievement is expected to lead to lower power consumption in a wide range of industrial equipment, paving the way for a carbon-neutral and sustainable society. Their findings were presented at the 22nd International Vacuum Congress (IVC-22) held from September 11 to 16.

Provided by JAEA

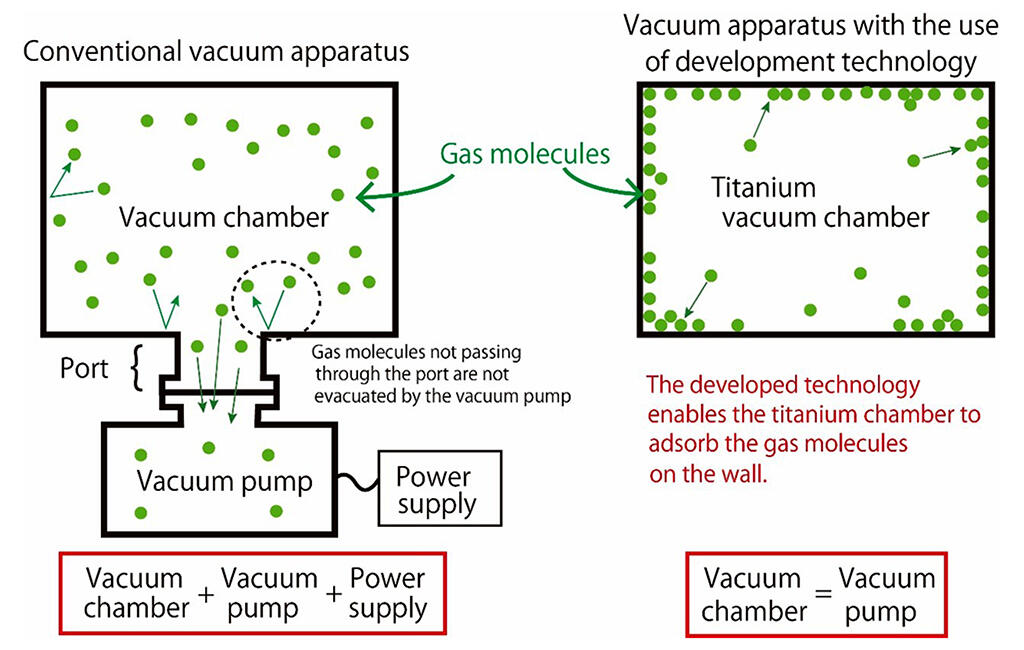

Electron microscope electron guns and accelerator beamlines are designed to maintain an ultra-high vacuum inside a specific device to prevent instabilities caused by adherence of gases. To create an ultrahigh vacuum inside the equipment, it is necessary to continue evacuating it with a vacuum pump that has a high pumping rate because once the equipment is kept in an ultrahigh vacuum, any gases that adhere to surfaces and walls of the equipment are released and the vacuum is no longer maintained. This has resulted in vacuum pumps becoming large and an increase in power consumption due to the larger size of the equipment.

Titanium is a low activation material used in the accelerator beamlines at J-PARC. It has getter performance, but the surface is usually covered with an oxide film which inhibits performance.

The research group has been studying how to reduce gases emitted from the surface of titanium into the vacuum in order to improve the vacuum performance of the beamline. In this study, the research group developed a method to modify the surface of a titanium vacuum vessel covered with an oxide film by processing (sputtering) it to expose the titanium, which is then coated with a metal that has getter performance (getter material) to protect it. Titanium is naturally covered with an oxide film, and even if the oxide film is removed, it will oxidize again. However, by modifying the surface with their method, it is possible to re-establish getter performance by a simple process (activation) of heating the vacuum vessel to about 200°C under vacuum for about one day and then returning it to room temperature, even if the vacuum vessel is opened to the atmosphere.

In conventional stainless steel vacuum vessels, when the gate valve was closed without the evacuation normally performed by a vacuum pump, the pressure decreased over time, dropping to 10-3 pascals (Pa) in one hour. On the other hand, a prototype vacuum vessel made of surface-modified titanium was able to maintain a near ultrahigh vacuum of 10-6 Pa for more than 200 days. This performance could be maintained after repeated opening of the vessel and activation.

The researchers further verified the prototype by attaching it to an electron microscope. They found that the prototype improved to 10-6 Pa, whereas the conventional vacuum pump alone was 10-5 Pa. Normally, when using an electron microscope, one must wait about 10 minutes for the vacuum to be restored when replacing an analysis specimen, but with the prototype connected, they confirmed that the vacuum was instantly restored, allowing analysis to be performed. If the vacuum vessel is heated to room temperature while evacuating, it can function as a gas storage vacuum pump, which is expected to lead to more compact equipment and lower power consumption.

"We expect this technology to contribute to a carbon-neutral, sustainable society," says principal researcher Kamiya. "For example, we expect that it can be used in the J-PARC beamline to reduce the number of existing pumps and improve the vacuum insulation performance of products such as laminated glass and thermos bottles, which are used in everyday life. Moving forward, we would like to understand the behavior of oxygen that enters the getter material to identify the underlying mechanism in greater detail."

This article has been translated by JST with permission from The Science News Ltd.(https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.