A research group led by Associate Professor Hiroki Ota and Associate Professor Kazuhide Ueno of Yokohama National University has created a lithium-ion battery that can be bent and stretched. This highly deformable, flexible and stretchable battery is expected to be used in the next generation of wearable devices. The results of the group's research were published in ACS Applied Materials & Interfaces.

Provided by YNU

Provided by YNU

Stretchable electronics is expected to be a fundamental technology underlying next-generation wearable devices. Although various stretchable sensors and interfaces have been proposed, rigid and large lithium-ion batteries are a major challenge in making devices and systems. Stretchable lithium-ion batteries capable of high output have been developed, but they cannot be used in air as is. This is because rubber is used for the exterior material, which allows gas and moisture to permeate.

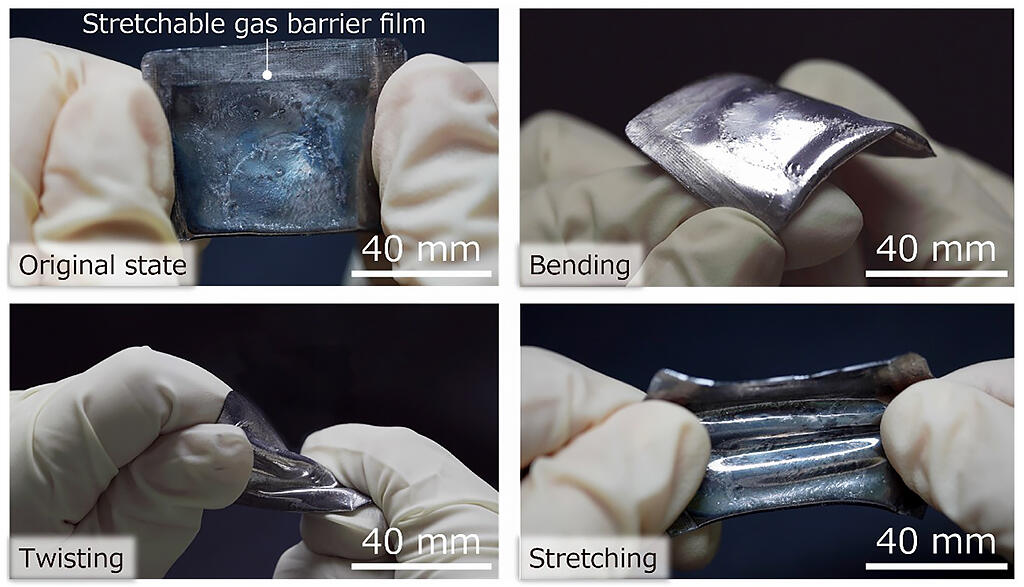

The research group solved this problem by using liquid metal as a packaging material to create a stretchable lithium-ion battery that can be used in ambient conditions.

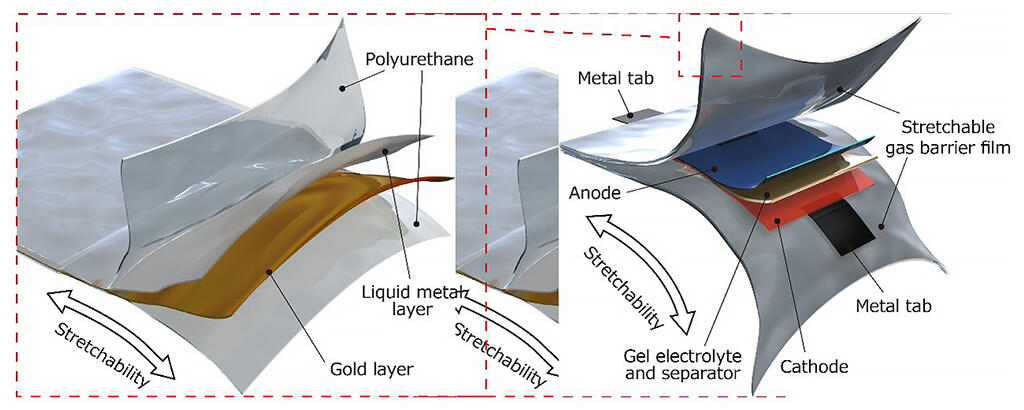

To make the battery, gold is first deposited on polyurethane rubber, and then liquid metal is coated on top. Although the gold film cannot withstand the expansion and contraction of polyurethane, the liquid metal coats the polyurethane rubber, inhibiting the permeation of gas and moisture. They used porous SBS (styrene-butadiene-styrene) as the electrode base material, and LTO (Li4Ti5O12) and LFP (LiFePO4) as the active materials for the anode and cathode, respectively. A gel separator was used as the separator to give the battery elasticity. Each material is then laminated on top of the other. The group created a stretchable lithium-ion battery by packaging these materials with the gas barrier film they developed.

When ordinary rubber materials were used as packaging materials, the battery voltage dropped within two hours in air, but the new gas barrier film used to package the battery held a higher voltage for more than 15 hours.

This article has been translated by JST with permission from The Science News Ltd.(https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.