Group led by Waseda University develops ultra-high molecular weight polyethylene gear

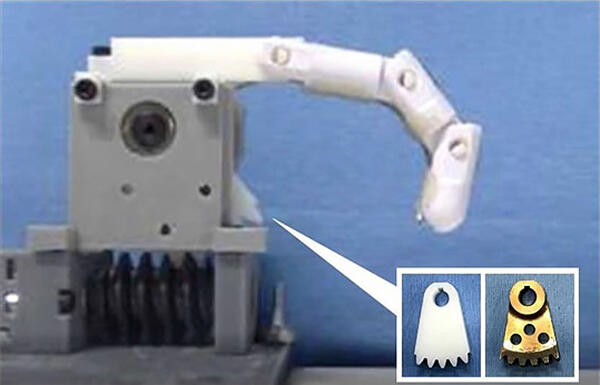

A research group led by Junior Researcher Takuya Otani of the Waseda Research Institute for Science and Engineering, and Professor Atsuo Takanishi of the Faculty of Science and Engineering, Waseda University, in collaboration with hide kasuga 1896 Inc., and Mitsui Chemicals, Inc., announced the development of a lightweight, low-friction robot gear made of ultra-high molecular weight polyethylene (UHMW-PE). The robotic finger equipped with the gear they developed reduces energy consumption by about 3% and weight by about 89% compared to using metal gears. The gear is expected to lead to the development of robots that save energy, make little noise, and can be easily spread to society. The group's research will be presented at an exhibition held at Gallery de Kasuga (Jingumae, Shibuya, Tokyo) on December 16. Their results were published in the September 19 issue of IEEE access, a publication of the Institute of Electronics and Electrical Engineers of America.

Provided by Waseda University

Most of the energy consumed during robot operation is in motor power, which increases as robots becomes larger and heavier. Therefore, to reduce energy consumption, the robot itself must be lightweight. Metal has been typically used for robot parts to support their own weight, but in recent years, there have been efforts to reduce weight by replacing not only the frames but also the gears of the drives with plastic. The research group focused on ultra-high molecular weight polyethylene (UHMW-PE). Polyethylene generally has a very high average molecular weight of 1.0 x 106 and is more resistant to abrasion and impact than other engineering plastics. Since it is composed entirely of carbon and hydrogen atoms, it is lightweight and chemical resistant.

Mitsui Chemicals provided HI-ZEX MILLION (0.93 g/cm2) and LUBMER (0.97 g/cm2), which have high wear resistance and sliding properties among UHMW-PEs, to produce the gears. The gears were about 89% lighter than metal gears (8.8 g/cm2). In order to match the conditions, both UHMW-PE gears were fabricated by cutting, and parameters such as the number of teeth and drive torque, which are related to the efficiency of the worm gear, were made equivalent. The research group incorporated the UHMW-PE gears into the robotic finger and then measured the energy consumed when moving the joints and compared it to metal gears.

They found that the energy consumption of the LUBMER gears fell by about 3% compared to metal gears. The HI-ZEX MILLION gears did not differ significantly from the energy consumption of metal gears. LUBMER has self-lubricating properties, whereas HI-ZEX MILLION does not. LUBMER's sliding properties were seen to reduce friction, leading to lower energy consumption. This property is expected to indirectly lead to oilless robots. Since most robots use gears, the research group found that they could reduce energy consumption simply by changing the material. By reducing the weight of other components, they hope to be able to realize high-speed and dynamic movements.

"This time we fabricated UHMW-PE gears using exactly the same design as the metal gears, but in the future, we would like to study and evaluate a suitable design to maintain strength," explained Otani. "The sliding characteristics of LUBMER also lead to a reduction in the noise level of the robot, which is an important aspect of the robot's suitability for daily use, and we will continue to evaluate this property in the future."

Journal Information

Publication: IEEE access

Title: Energy Efficiency Improvement of a Robotic Finger With Ultra High Molecular Weight Polyethylene Gear

DOI: 10.1109/ACCESS.2022.3207752

This article has been translated by JST with permission from The Science News Ltd.(https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.