A joint research team led by Senior Researcher Kota Shiba of the National Institute for Materials Science (NIMS), Professor David A. Weitz of Harvard University, and Professor Luyi Sun of the University of Connecticut, has designed and fabricated a simple device that colors gases according to their properties when they flow into it, and demonstrated that gases can be identified by their color. This is a new method to easily visualize and identify any gas by using the pressure generated by the inflow of the gas to produce structural colors. It is anticipated that it will be used in various fields such as the environment, safety, and health care. The group's research was published in the online edition of Advanced Science.

Provided by NIMS

Nearly all gases are colorless and invisible. Gas has previously been visualized by targeting its flow and using methods based on temperature changes using an infrared camera or dispersing fine particles called tracer particles in the gas. However, these methods require special equipment, and it was difficult to visualize any gas uniformly and analyze the properties of a gas from the visualized image.

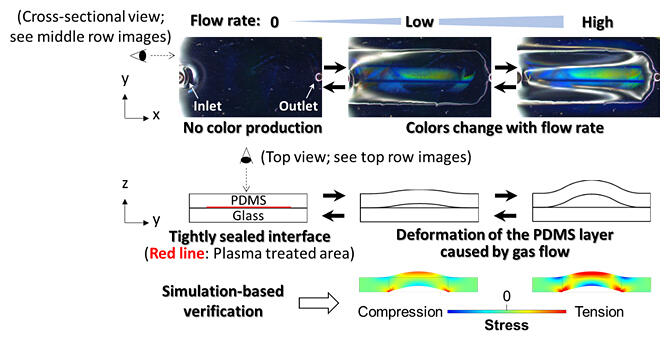

The research team fabricated a device capable of imaging and differentiating various gases using a wide range of colors (structural colors) by shaping polydimethylsiloxane (PDMS), a soft material, into a slab, treating part of the slab surface with argon plasma, and then adhering the surface to a glass substrate.

The plasma treatment promotes bridging inside the PDMS, resulting in the formation of a film on its uppermost surface that is several hundred times harder than untreated PDMS. When a compressive force is applied to the two-layer structure with significantly different hardnesses on the top and bottom surfaces, the uppermost surface is specifically deformed to form a periodic wrinkle-like structure. Structural color appears because this periodic length takes a value (several hundred nanometers to several micrometers) close to the wavelength of visible light (380 to 780 nm).

The device is designed so that the argon plasma treated PDMS surface and the glass substrate are in perfect contact with each other, and only the part through which the gas passes is deformed (compressed) when the gas is allowed to flow in by forcing the surfaces open. This deformation, under the condition of a constant temperature, depends on the physical phenomenon of flow-derived pressure, and therefore occurs no matter what gas passes through the system. Therefore, in principle, it is possible to identify any gas. The PDMS can also be applied to on/off display technology, because if the gas flow stops, the PDMS will adhere to the glass as it was before, and the color will disappear completely.

The structural color in this case depends on the flow rate, viscosity, and density of the gas, so if the type of gas is known, the device can be used as a flowmeter. In addition, since the structural color depends on both viscosity and density, the complex dependence of the structural color can be used for identification. Specifically, if multiple gases are injected sequentially at a constant rate, each gas will develop a unique color according to its characteristics (viscosity, density), and this can be used to identify the gas. Using this approach, "learning data" can be obtained by measuring numerous gases in advance using these as independent variables, which can be used to qualitatively and quantitatively analyze unknown gases.

In future research, the group hopes to improve and optimize the sensitivity of the device with the aim of identifying ambient gases and biological samples.

Journal Information

Publication: Advanced Science

Title: Visualization of Flow-Induced Strain Using Structural Color in Channel-Free Polydimethylsiloxane Devices

DOI: 10.1002/advs.202204310

This article has been translated by JST with permission from The Science News Ltd. (https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.