Senior researcher Yasunori Minami of the Silicon Chemistry Team, Interdisciplinary Research Center for Catalytic Chemistry at the National Institute of Advanced Industrial Science and Technology (AIST), has developed the world's first depolymerization method that can break down polyetheretherketone (PEEK), a high‐performance thermoplastic polymer known as a super engineering plastic, into monomers.

Provided by AIST

Although PEEK is produced in smaller quantities than other plastics, it is highly stable and is an essential material for advanced products. However, there are no examples of its chemical recycling, which is problematic from the perspective of resource recycling. To solve this problem, researchers have tried to develop technology to depolymerize PEEK.

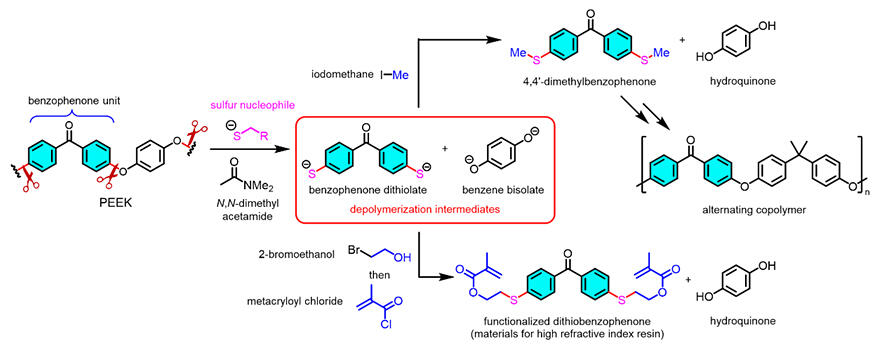

The technology uses the organic sulphur compound thiols and bases as depolymerising agents, which can break down PEEK into monomers in less than 19 hours at a much lower temperature of 150℃ than the typical thermal decomposition temperature of 600℃ ‐1,500℃ for resins. The process results in yields of the precursor of the polymerizable monomer (dithiobenzophenone) and the raw monomer of PEEK (hydroquinone) as high as 93% and 95%, respectively. The process can also selectively break down the PEEK component, whether it contains resins such as polypropylene or polyamide, or composite PEEK materials such as carbon fiber‐reinforced PEEK.

Various polymers, such as benzophenone‐bisphenol A‐alternating copolymers, can be synthesized from the resulting monomers.

The new technology is expected to pave the way for the chemical recycling of PEEK. It can also be applied to the depolymerization of super engineering plastics other than PEEK, thus contributing to the circular economy of stable resin materials.

"In the development process, it took a lot of trial and error until we were able to break it down into monomer units in high yields," said Minami. "In the future, we would like to use the results as a gateway to develop efficient depolymerization technologies for various super engineering plastics other than PEEK and other stable plastics, and for the development of new catalysts, with the aim of implementing them in society."

■ Super engineering plastic: High performance resins with very high heat resistance and mechanical strength. They can be used for extended periods of time in high‐temperature environments at temperatures of 150℃ and above. They are used as an alternative material to metal due to their light weight and high mechanical strengths.

■ Polyetheretherketone (PEEK): A thermoplastic resin that offers high performance and is a leading super engineering plastic. However, it is also an expensive material.

Journal Information

Publication: Communications Chemistry

Title: Depolymerization of robust polyetheretherketone to regenerate monomer units using sulfur reagents

DOI: 10.1038/s42004‐023‐00814‐8

This article has been translated by JST with permission from The Science News Ltd. (https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.