The need for bone substitute materials is increasing due to the progression of Japan's hyper‐aged population and the diversification of bone diseases. Bone substitute materials that are mechanically reliable and unlikely to be rejected by bones must have the contradictory properties of 'being strong and flexible' or 'easy to process and resistant to deformation.' However, this is a major challenge in materials science as it is difficult to develop materials that simultaneously manifest these characteristics.

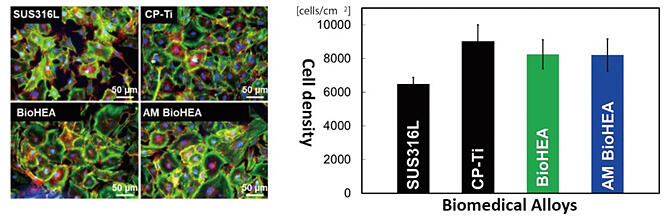

A research group led by Professor Takayoshi Nakano of the Graduate School of Engineering at Osaka University, has succeeded in developing a new 'bio‐high entropy alloy (BioHEA)' that is strong and fits to the body like a bone itself by combining a super multi‐component alloy consisting of six elements and laser metal 3D printing that enables ultra‐rapid cooling, with the aim of developing a strengthening mechanism at the nano‐ (parts per billion) and atomic levels. The alloy is made of titanium, zirconium, hafnium, niobium, tantalum and molybdenum.

BioHEA has typically been a five‐component alloy, but by designing a six‐component alloy to facilitate solid solution formation and using an ultra‐rapid cooling process, the new BioHEA is 1.4 times stronger than that of a cast material of the same composition. Through ultra‐rapid solidification, the researchers succeeded in scaling down the range of phase separation from the usual several tens of micrometers (1/1,000,000) to nanometers, creating a solid solution with atomic orientation. The forced mixing of constituent elements and lattice distortion at the nano‐level resulted in high strength, and the atomic orientation in specific directions is believed to have given it suppleness.

The new BioHEA provides a clue to elucidation of nanomechanical phenomena and is anticipated to be used for implant materials in the fields of orthopedics and dentistry. In addition, as it is composed of elements with high melting points, it is also attracting attention as a heat‐resistant aerospace material.