Upon heating, particles bond with each other (i.e., undergo sintering) at temperatures lower than their melting point. Because the surface area of nanoparticles is very large relative to their volume (and the area corresponding to the surface occupies a large portion of the particles), dust or moisture in the atmosphere, which do not typically affect sintering, can influence the sintering behavior of nanoparticles. This means that it is difficult to directly observe the changes in the appearance of such particles during sintering.

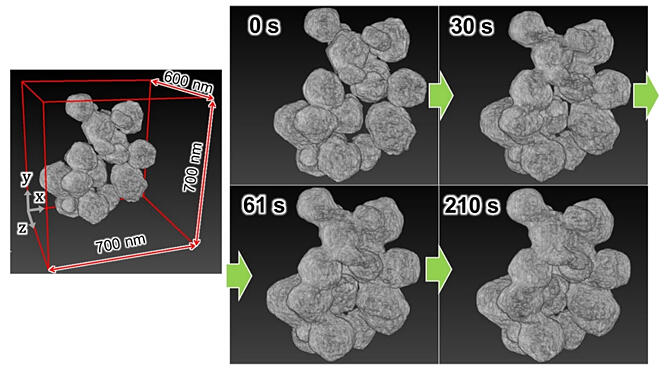

A research group comprising Assistant Professor Shiro Ihara, Associate Professor Hikaru Saito, and Professor Mitsuhiro Murayama of the Institute for Materials Chemistry and Engineering at Kyushu University; Mizumo Yoshinaga of the Interdisciplinary Graduate School of Engineering Sciences (IGSES) at Kyushu University (currently at Toppan Printing); Graduate Student Kota Wada (a master's student) and Professor Satoshi Hata at the IGSES; and President Hiroya Miyazaki of Mel-Build has developed a transmission electron microscopy (TEM) sample holder for in situ analysis with heating. The sample holder can be used to three-dimensionally analyze the sintering of copper nanoparticles with an average size of 150 nm. Thus, a four-dimensional (4D) analysis of the sintering was performed by adding time as a variable to the three-dimensional (3D) space. A 4D analysis of the sintering of nanoparticles at the nanoscale level was performed for the first time and the results were published in Nanoscale.

Provided by Kyushu University

TEM analysis is performed by irradiating samples with electron beams; this electron beam irradiation causes small impurities to deposit and agglomerate on sample and equipment surfaces. Such contamination hinders sintering. In addition, 3D TEM analysis requires collecting numerous images from various angles, similar to medical X-ray computerized tomography (CT) imaging. Consequently, electron beams can induce sample contamination. This is a considerable drawback, particularly for experiments that add time as a variable for data acquisition.

Therefore, the research group developed a TEM sample holder for in situ observations while heating. The tip can be stored in the axis of the holder. The tip features a rubber ring that can seal the holder when the tip is retracted.

A dispersion of copper nanoparticles in ethanol was dropped onto a microelectromechanical systems (MEMS) chip in an argon-filled glove box, and then it was stored inside the TEM holder. The sample was observed without exposing it to the atmosphere by simply inserting the holder into the TEM instrument.

The MEMS chip was equipped with a current-carrying microheater with a low thermal capacity, which promotes rapid temperature changes and allows for instantaneous temperature control. This allowed researchers to observe changes in morphology during sintering at ≥ 350 ℃, followed by an abrupt decrease in temperature, which temporarily stopped the progress of sintering.

In this study, changes in morphology were observed while the sample was heated to 200 ℃ to avoid sample contamination by electron irradiation as much as possible; however, the progress of sintering was not observed at this temperature. The copper nanoparticles (manufactured by Mitsui Kinzoku) used in this study presented a core−shell structure. The copper nanoparticles featured numerous shell particles with an average diameter of ≤ 10 nm surrounding a core particle with an average diameter of 150 nm.

The TEM images show that during heating, the surrounding shell particles underwent diffusion, the shells formed aggregates, and sintering was initiated. This is a critical finding for understanding low-temperature sintering of nanoparticles. To avoid sample contamination, the electron dose was decreased considerably, and the noise was increased. However, the increase in noise was mitigated by using a BM3D noise filter.

Because omnidirectional imaging similar to that achieved using medical CT instruments could not be performed, erroneous calculations caused by insufficient tilt angles were mitigated by adopting a reconstruction algorithm that incorporated compressed sensing. These allowed the use of the lowest electron dose for all 3D TEM experiments using electron microscopes.

By combining the construction of a transport system that prevents atmospheric exposure with low-electron-dose observations, researchers can observe the time evolution of copper nanoparticles, a material sensitive to sample contamination, in the 3D space, i.e., they can perform 4D analyses. This method is expected to have further applications for analyzing the synthesis of materials fabricated using highly reactive or anaerobic substances.

Journal Information

Publication: Nanoscale

Title: In situ electron tomography for the thermally activated solid reaction of anaerobic nanoparticles

DOI: 10.1039/D3NR00992K

This article has been translated by JST with permission from The Science News Ltd. (https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.