On June 26, a research group at the Backend Device Technology Laboratory of the Advanced Device Research Laboratories of the Corporate Research & Development Center, Toshiba Corporation, announced the development of a compact sensing technology capable of simultaneously measuring all gases contained in a mixture comprising multiple gases, such as carbon dioxide, hydrogen and carbon monoxide, at high speeds in real time.

Provided by Toshiba

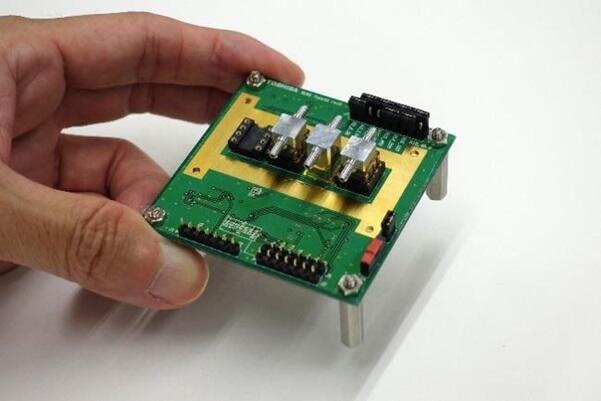

The module size of this technology is less than 1/200 of that of conventional gas chromatography technology, and its monitoring speed is more than 150 times faster than that of conventional gas chromatography. The prototype machine successfully performed simultaneous measurement of three types of gases. The technology is aimed to be commercialized in 2026 and contribute to the realization of carbon neutrality by 2050.

Generally, in CO2 recycling technologies, which are important for achieving carbon neutrality, real-time monitoring of the compositions and concentrations of gases during reactions is essential to achieve highly efficient recycling. However, during the involved gas reactions, byproduct gases and water vapor are typically generated in addition to CO2, and these gases exist in a mixed state.

In principle, conventional gas chromatography requires long columns for separation, resulting in large apparatus sizes, which hinder real-time monitoring and extend the measurement times up to several minutes. Therefore, the research group aimed for detection only using a gas sensor without a column.

First, they examined the possibility of using various types of gas sensors, with a particular focus on thermal conductive sensors with high resistance to poisoning (resistance to gases). Thermal conductivity type sensors generally measure gases according to temperature changes in the membranes of sensor components based on the thermal conductivity specific to each gas type. Thermal conductivity sensors can normally measure a mixture containing up to two gases, but the research group devised a method employing two thermal conductivity sensor elements with different sensitivities. The detection of multiple gases was achieved by developing an algorithm to determine the gas concentration based on the output of each sensor and the inverse function of the respective pre-calibration curves.

Furthermore, using proprietary micro-electromechanical systems (MEMS) technology, they succeeded in simultaneously fabricating multiple thermal conductive gas sensors on a fingertip-sized ultra-compact chip.

A prototype machine was constructed with gas sensors, nozzles for gas introduction, and a dedicated circuit. The size of the prototype machine is approximately 106 square centimeters, less than 1/200 of the average size of conventional gas chromatography equipment. To verify the equipment performance in an actual environment, the research group installed a cell generating CO via CO2 electrolysis, which is assumed in CO2 recycling technology, and simultaneously measured the concentration of each gas contained in a mixture of CO2, H2 and CO gases in a humidified state. Consequently, each gas concentration could be measured accurately with a measurement time of 1.7 seconds, 150 times faster than that with conventional gas chromatography technology.

Although CO is highly toxic, the thermal conductivity type equipment is highly tolerant as it is devoid of a reaction membrane, and they confirmed that CO can be monitored without any practical effects. In the future, based on the acquired results, the research group plans to optimize the structure and algorithm of the sensors and conduct further demonstration experiments with the aim of commercialization in 2026. When monitoring more than three types of gases, the increase in noise is an issue; however, they aim to contribute to the acquisition of highly reliable carbon footprint data for more gas types.

The developed technology is also expected to be applied for stand-alone gas sensing, indoor air monitoring and intestinal environment monitoring using exhaled hydrogen, as well as for leak detection of hydrogen gases.

This article has been translated by JST with permission from The Science News Ltd. (https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.