Agricultural mulch films are used to cover the surface of fields when growing vegetables to retain moisture and temperature and prevent weeds and pests. In recent years, the use of biodegradable plastic mulch film that is decomposed by being plowed into the field after use is expanding to save labor at agricultural sites. However, in this application, because it is necessary to maintain strength during cultivation, biodegradable plastic with high strength is used, which take long periods to decompose.

To address this, a research group in the Division of Climate Change Mitigation Research of the Institute for Agro-Environmental Sciences at the National Agriculture and Food Research Organization (NARO) has undertaken the challenge of developing a technology to decompose degradable plastic mulch films quickly by using a decomposing enzyme derived from yeast that lives in rice straw and spraying a suspension of the same enzyme after use. The research group recently announced the development of the technology and the successful demonstration of its effectiveness in a field. The results were published in the international academic journal Scientific Reports.

Provided by NARO

A research group led by Hiroko Kitamoto (Former Assistant Group Leader), Principal Scientist Hirokazu Ueda, and Principal Scientist Yuka Yamashita believe that farmers would prefer using agricultural mulch film if the film's decomposition could be accelerated at the timing desired by the user, and they have focused their efforts in this direction.

The research group has succeeded in isolating and culturing the yeast 'Pseudozyma antarctica,' which secretes an enzyme that actively decomposes biodegradable plastics. This bacteria was endemic to rice. The group has named the enzyme secreted by the bacteria 'PaE.' The researchers have selected microorganisms that decompose rapidly and developed mass culture methods.

Biodegradable plastics are polymers composed of ester bonds between alcohols and organic acids. PBSA, PBS, PBAT, and PLA are typical materials that are widely used. Among them, PBSA has the fastest biodegradation rate, and the following materials have the rate slowing down in the order of mention.

Agricultural mulch film and other products are manufactured by mixing and molding these materials. Predicting the decomposition rate is difficult due to a variety of factors, including the blend ratio of materials, additives, type of vegetable to be grown, growing season, environment, weather conditions, and decomposition capacity of the field.

In this study, the research group confirmed that 'PaE' can randomly cleave not only PBSA and PBS but also PBAT, which decomposes slowly, to monomers. Three commercially available biodegradable mulch films and films made solely from each material (PBSA, PBS, and PBAT) were confirmed to be decomposed by immersion in PaE solution (27 U/50 ml buffer).

PLA, which is the most difficult material to decompose, can be decomposed if it is non-crystalline; however, the decomposing rate of crystallized PLA was found to be about 1/1000 times that of PBSA. Furthermore, based on the results of these indoor experiments, the researchers conducted demonstration experiments in actual fields.

When the PBSA film was sprayed with PaE suspension in a plastic greenhouse, it was observed that the film decomposed from the point of liquid accumulation, and that as it dried, the entire film cracked and deteriorated overnight.

Next, the commercially available biodegradable mulch film was tested. It is more difficult to decompose than the PBSA film in the field (open-field cultivation), and the treated and non-treated areas were spread in the field for two months without growing vegetables on 15-meter ridges. Then, the treated areas with PaE and the non-treated areas without PaE were placed in alternating rows.

In this experiment, calcium carbonate powder was mixed with the PaE solution to maintain pH conditions conducive to enzyme action.

As a result, the treated mulch film became thinner the next day, and visual and electron-microscopic observations revealed that cracks increased, and that the strength of the film was reduced. The number of cracks on the film surface increased with increasing PaE concentration.

It is recommended that biodegradable mulch film be plowed into the soil immediately after use.

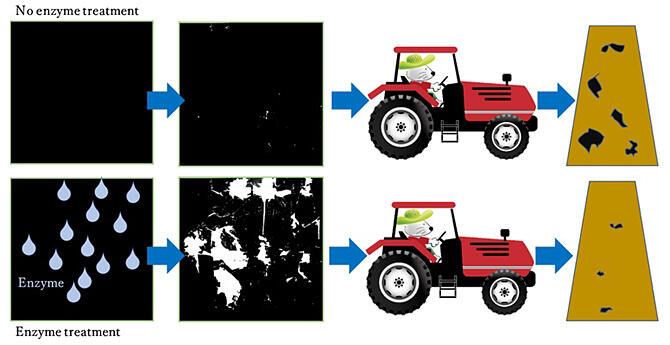

The day after the PaE treatment, all fragments of each mulch film from the PaE-treated and non-treated areas were dug up and collected by plowing with a tiller, and fragment size and total weight were compared for the two areas.

Results confirmed that in the PaE-treated area compared to the non-treated area, the number of large fragments decreased, the size of the fragments decreased, and the total weight of the fragments decreased.

It was also confirmed that the PaE treatment was effective on several commercially available biodegradable mulch films with different compositions, even under the temperature conditions of around 31 ℃ in early summer and 14 ℃ in late autumn.

The enzymes need an appropriate amount of water to work, and hence, enzymes spraying is performed at times when heavy rains and daylight hours should be avoided.

Currently, with the cooperation of farmers, the research group is conducting trials at actual cultivation sites and verifying the changes in decomposition rate of the mulch film in the soil after plowing. They will continue to consider scaling up the culture scale.

Journal Information

Publication: Scientific Reports

Title: Accelerated degradation of plastic products via yeast enzyme treatment

DOI: 10.1038/s41598-023-29414-1

This article has been translated by JST with permission from The Science News Ltd. (https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.