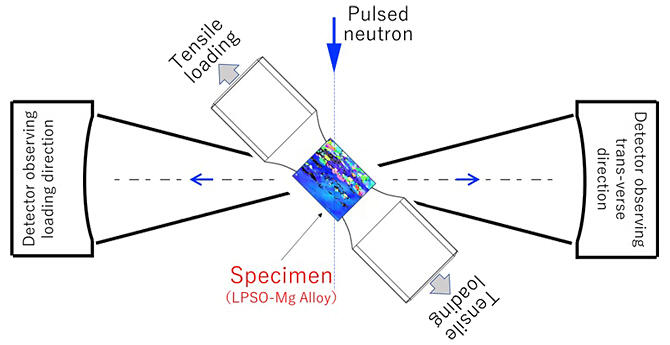

A research group led by Principal Researcher Stefanus Harjo and his colleagues of the J-PARC (Japan Proton Accelerator Research Complex) Center at the Japan Atomic Energy Agency (JAEA), and Professor Michiaki Yamasaki of the Graduate School of Science and Technology at Kumamoto University has developed a high-strength Mg alloy (LPSO-Mg) that exhibits increased strength upon high-temperature extrusion. The group has clarified the mechanism underlying the large increase in strength. The behavior of each structural phase was analyzed by examining the specimen under tensile deformation through neutron diffraction on a high-performance engineering materials diffractometer (TAKUMI) at the J-PARC.

It was found that both Mg and LPSO phases, which constitute the alloy, contributed to the increased strength. This finding is expected to lead to further strengthening, cost reduction, and higher functionality of Mg alloys. The results were published in the 15 August 2023 issue of the international journal Acta Materials.

Provided by JAEA

The high-strength LPSO-Mg alloy developed by Kumamoto University consisted of an Mg matrix phase and a long-period stacking order (LPSO) phase, thus combining the lightweight characteristics of Mg and the strength per density comparable to that of martensitic steel—the strongest steel.

High-temperature extrusion significantly increased the ductility and strength, and the increase in strength was considered to be due to the introduction of kink zones in the LPSO phase during processing. Kink zones are deformed zones where the slip surface is locally bent and can be observed with a scanning electron microscope. The low content of the LPSO phase significantly increased the strength at low extrusion ratios and decreased the strength at high extrusion ratios, which could not be explained by the kink zone alone. The behavior of each phase during the high-temperature extrusion was unknown.

Therefore, to clarify the mechanism by which the strength increases, the research group conducted in situ neutron diffraction experiments on the same alloy that had been extruded at a high temperature at two different extrusion ratios (5.0 and 12.5), while subjecting the alloy to tensile deformation. The stress borne by each phase was measured. For the experiments, alloys with 25% of the LPSO phase were subjected to high-temperature extrusion at 350 ℃. Unprecedentedly, the yield strength of not only the LPSO phase but also the Mg phase was found to increase due to the extrusion processing.

In the case of the lower extrusion ratio of 5.0, the Mg phase is multimodal (i.e., different microstructural forms are mixed within the Mg phase) due to the formation of a Mg phase that is elongated in the extrusion direction and a recrystallized Mg phase consisting of smaller sized grains. Furthermore, this combination was found to effectively improve the strength of the entire sample. In contrast, at the higher extrusion ratio of 12.5, no clear Mg phase was observed. The contribution of the Mg phase toward the strength was smaller at a higher extrusion ratio than at a lower extrusion ratio, while the contribution of the LPSO phase toward the strength was larger.

Mg alloys are prone to defects during casting, and defects are generally reduced by increasing the extrusion ratio. However, this study shows that it is possible to form multimodal microstructures and increase the strength and ductility by reducing the extrusion ratio. The strength can be improved further by controlling the structural morphology of the Mg phase.

Harjo said, "In the future, we would like to prepare various multimodal structures by varying the extrusion conditions and volume conditions of the LPSO phase and investigate their effects on the mechanical properties, and we hope to eventually build a database."

Yamasaki stated, "This achievement indicates the possibility of realizing strength without relying on the LPSO phase (also called the reinforcing phase), which contains expensive and heavy metals like zinc and yttrium. By controlling the heterogeneity, we expect to develop alloys that exhibit both strength and ductility."

Journal Information

Publication: Acta Materialia

Title: Strengthening of αMg and long-period stacking ordered phases in a Mg-Zn-Y alloy by hot-extrusion with low extrusion ratio

DOI: 10.1016/j.actamat.2023.119029

This article has been translated by JST with permission from The Science News Ltd. (https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.