When general chemical fibers are produced, polymers are dissolved by applying high temperatures or using organic solvents, extruded under high pressure, and then solidified into fibers using high temperatures or organic solvents. Silkworms, on the other hand, produce fiber from water-soluble silk at room temperature. If it was possible to mimic this production method, it would lead to the development of an environmentally friendly and energy-efficient spinning technology; however, this has yet to be achieved. One reason for this is that the process through which silkworms rapidly create solid fibers from an aqueous solution is still unknown.

A joint research group comprising Associate Professor Yu Suzuki of the Department of Engineering at the University of Fukui, Emeritus Professor Akira Naito of Yokohama National University, and Specially Appointed Professor Tetsuo Asakura of the Faculty of Engineering at Tokyo University of Agriculture and Technology (at the time of the research), succeeded in tracking in real time how silk changes from its pre-fiber structure to its post-fiber structure under pressure. A natural silk aqueous solution produced by silkworms was used in this method. These results were published in the Journal of the American Chemical Society.

Provided by the University of Fukui

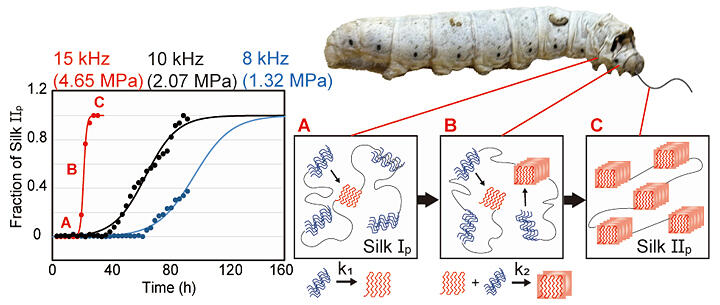

The joint research group focused on the pressure exerted at the silkworm's spout as a factor that causes the transformation of silk from an aqueous solution into fiber. The group used solid-state NMR (Nuclear magnetic Resonance) measurements to track in real time the process by which the natural silk aqueous solution present in the body of a silkworm changes from its pre-fibrotic structure (Silk 1) to its post-fibrotic structure (Silk II) under pressure. To obtain a high-resolution spectrum in solid-state NMR, the sample tube was rotated at high speed during measurement (magic angle spinning).

In this study, they successfully tracked the real-time structural transition of silk molecules under pressure by utilizing the pressure derived from the centrifugal force applied to the sample during magic angle spinning. Next, they performed the measurement for observing components with relatively low mobility and the measurement for observing highly mobile components repeatedly and alternatively. Thereby, they succeeded in tracking the structural changes in Silk I and Silk II separately.

They have demonstrated the presence of an intermediate structure during the structural transition. It is proposed that this intermediate structure is a monolayer lamellar structure. In addition, a strength change of the post-fibrillation structure was observed during real-time monitoring, which indicated that the structural transition consists of two stages: lag time and fibril growth. Furthermore, as the pressure was increased, the lag time became shorter, and the fibril growth rate increased. This indicates that the structural transition rate was pressure dependent. These results indicate that the pressure-induced structural transition of silk can be explained by a two-step autocatalytic reaction mechanism. This is the first research to experimentally demonstrate that pressure, in addition to shear stress and tension, is an important factor for fiber formation in the silkworm fiber production process.

Journal Information

Publication: The Journal of the American Chemical Society

Title: Real-Time Monitoring of the Structural Transition of Bombyx mori Liquid Silk under Pressure by Solid-State NMR

DOI: 10.1021/jacs.3c04361

This article has been translated by JST with permission from The Science News Ltd. (https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.