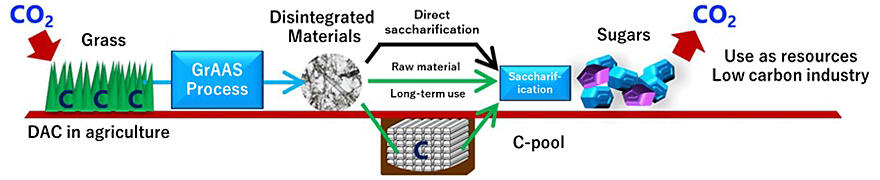

Ken Tokuyasu, Leader of the Biomaterials Development Group, Division of Food Processing and Biomaterials Research, Institute of Food Research, NARO and his colleagues, in collaboration with Saitama University and the University of Tokyo, announced on January 26 that they have developed a new technology, the GrAAS (Grass Upcycling by Activated Acid into Sugar pool) process, in which acid treatment at room temperature is used to unravel stem and leaf fibers. Moreover, they have clarified the characteristics of the fibers produced with this technique. This process improves the saccharification of plant fibers, allowing them to be converted into biofuel and other products. The technique is expected to lead to the creation of low-carbon and decarbonized industries. The study results were published in the international academic journal Bioresource Technology Reports.

Provided by NARO

The scientists at NARO conducted research to convert stems and leaves, which are prone to decay and alteration, into fibers that can withstand long-term use. In the past, a method of decomposing wood and other materials into sugars via the action of hydrogen chloride gas was developed. The problem was that the decomposition reaction was too fast, and the fibers fell apart.

In this present study, a hydrogen chloride gas generation method, in which a calcium chloride solution is mixed with hydrochloric acid, was used to derive a milder reaction. Consequently, the "GrAAS (grass upcycling by activated acid into the sugar pool) process" was developed. The process grinds straw powders modified by activated hydrochloric acid under a liquid or vapor phase condition, resulting in a suspension that is highly dispersible in water. Enzymatic saccharification of this suspension results in a higher recovery of sugars than that obtained from the control suspension (in which calcium chloride solution was used instead of the reaction solution).

Converting underutilized stems and leaves into fiber will increase the efficiency of paper, cardboard, and lignocellulosic nanofiber (a highly functional fiber material made by micronizing cellulose without highly refining it) production and provide a carbon pool suitable for long-term use. The fibers can be enzymatically saccharified to recover their sugars, which can then be converted into biofuel or bioplastic materials, contributing to a low-carbon economy and decarbonization. Additionally, the new stem/leaf-derived material, from which sugars can be recovered after long-term use, can be stored for a long time as a "sugar pool" and converted into fuel, feed, or food when needed.

As an example of social implementation, assuming that 5,000 tons of rice straw is collected from approximately 1,000 hectares of rice paddies, the amount of fiber produced will be 3,500 tons, assuming a yield of 70%. In the case of producing "sugar bars" as a sugar pool, the production scale would be 2,800 tons (equivalent to approximately 4,100 tons or 9.7 million units of CO2) at an 80% yield rate.

Tokuyasu said, "We have been conducting research with the aim of converting polysaccharides such as cellulose, the main component of rice straw, into a resource that can be made edible. In addition to its use as a fiber or another type of material, we would like to accelerate the development of its applications, including the possibility of fermenting it and converting it into vitamins and functional ingredients or using it as a dietary fiber or feed."

Journal Information

Publication: Bioresource Technology Reports

Title: Hydrogen chloride treatment of rice straw for upcycling into nanofibrous products for sugar pool

DOI: 10.1016/j.biteb.2023.101717

This article has been translated by JST with permission from The Science News Ltd. (https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.