A research group led by Associate Professor Kazuhiko Ninomiya of the Radioisotope Research Center at the Institute for Radiation Sciences, Osaka University, in collaboration with International Christian University, Kyoto University, the Institute of Materials Structure Science at the High Energy Accelerator Research Organization, the Advanced Science Research Center at the Japan Atomic Energy Agency, the National Museum of Japanese History, and others, has announced the development of a technique for non-destructively quantifying trace amounts of carbon in steel using muons, one of the elementary particles. This advancement is expected to be applied to the analysis of iron and steel cultural assets. The results were published in the January 20, 2024 issue of the international academic journal Scientific Reports.

Provided by Osaka University

The primary component of steel is iron (Fe), with properties such as hardness adjusted by incorporating various elements as required. Among the elements influencing the properties of steel, carbon holds particular significance. It exists in steel at concentrations as low as less than 2%. Excessive carbon content renders steel hard but prone to chipping, while insufficient amounts result in a softer material that is easier to machine.

While determining the carbon content in steel is crucial for understanding its properties, traditional methods like X-ray fluorescence analysis, commonly employed for non-destructive analysis, are inadequate for carbon detection. As a result, non-destructive analysis of carbon in steel was not feasible. The problem of X-ray fluorescence analysis is inapplicability to valuable items such as cultural assets.

In this study, the research group successfully analyzed trace amounts of carbon in steel in a position-selective and non-destructive manner using the world's most intense muon beam from the Muon Science Establishment (MUSE) at the Materials and Life Science Experimental Facility (MLF) within the Japan Proton Accelerator Research Complex (J-PARC).

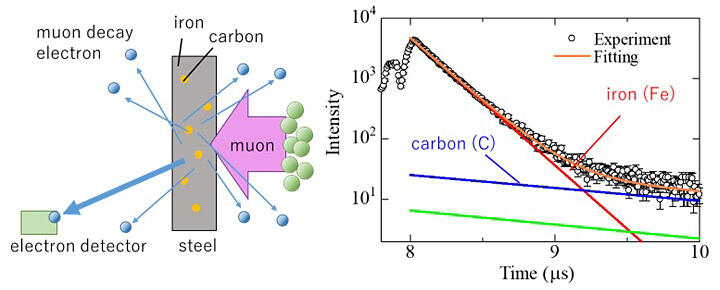

When muons are injected into a material and subsequently stopped, they capture atoms within the material, resulting in the formation of strange atoms called muonic atoms. The process of muon decay into electrons competes with the reaction of muons being absorbed by nuclei after forming muonic atoms. It is understood that the apparent lifetime of a muon varies depending on the type of atom by which the muon is captured. For example, the apparent lifetime is 200 ns when muons are captured by iron, whereas it extends to 2 µs when captured by carbon. Recognizing that the lifetime of a muon varies for each atom, a study was conducted to investigate whether information about the elemental composition of materials could be obtained by measuring the electrons emitted during muon decays.

Muons are quantum beams known for their high penetrating power, and the depth at which they can be stopped (and subsequently analyzed) within a material can be controlled based on their energy level. It has been confirmed that utilizing muons enables the non-destructive quantification of carbon content in steel, even at concentrations of less than 1%. In principle, this method can be applied to areas beyond the analysis of carbon in steel and can also be used for analyzing oxygen in metals.

Ninomiya said, "Typically, non-destructive analysis of light elements like carbon within materials is challenging. However, our study demonstrates the feasibility of utilizing the advanced quantum beam 'muon' to investigate carbon in steel. Steel is a material familiar to us all. I will be glad if this advancement can pave the way for increased utilization of quantum beams in industry."

Journal Information

Publication: Scientific Reports

Title: Development of a non-destructive depth-selective quantification method for sub-percent carbon contents in steel using negative muon lifetime analysis

DOI: 10.1038/s41598-024-52255-5

This article has been translated by JST with permission from The Science News Ltd. (https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.