A research group led by Specially Appointed Assistant Professor Hiroki Miyajima, Specially Appointed Assistant Professor Masaru Mukai, Professor Shoji Maruo and Associate Professor Kazutoshi Iijima of the Faculty of Engineering at Yokohama National University announced that they have successfully constructed microstructured organic−inorganic composite 3D models composed of substances that mimic bone. Microstructured hydrogel models consisting of gelatin derivatives were fabricated via laser 3D printing and surface-modified with an inorganic material. The results are expected to lead to the realization of regenerative medicine by reproducing a microenvironment close to that of a living body. Their achievement was published in the international scientific journal ACS Biomaterials Science & Engineering in the February 12 issue.

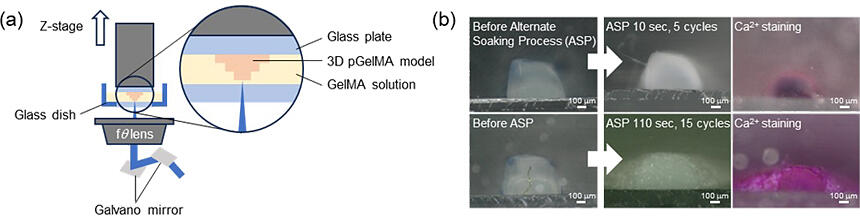

b) Modification of pGelMA line models (600 µm width) with hydroxyapatite.

Provided by Yokohama National University

Bone is known to be an organic−inorganic composite material composed mainly of an organic substance (collagen) and hydroxyapatite, which consists of inorganic substances (calcium and phosphoric acid). Bone marrow, located inside the bone, plays a fundamental role in the maintenance of vital activities as a site for the production of blood cells and immune cells. In the bone marrow microenvironment, hematopoietic stem cells, which are the source of blood cells and immune cells, remain in an undifferentiated state during proliferation as they interact with other cells. However, growing hematopoietic stem cells in a similar manner ex vivo has proven to be difficult.

The research group has been developing 3D bone models that mimic bone, based on the idea that bone composition and internal structure play a significant role in the original function of bone and bone marrow in living organisms. Meanwhile, it is difficult to reproduce the microenvironments found in the body using conventional material extrusion methods due to their low modeling precision.

In this study, the research group constructed microstructured hydrogel 3D models via laser 3D printing of cross-linkable gelatin. They subsequently developed a new method to convert the resulting 3D models into inorganic composites without significant alterations to their structure, effectively coating them with inorganic substances. In particular, a photoinitiator is added to gelatin methacrylate (GelMA), a chemically modified gelatin with excellent biocompatibility. Three-dimensional cross-linked GelMA hydrogel models of arbitrary microstructures were constructed via laser 3D printing with light irradiation. The constructed models were subsequently converted into composites with inorganic substances through alternate soaking in solutions containing calcium and phosphate ions. The research group also confirmed that different inorganic composites were obtained by changing the immersion time and number of cycles.

This method allows for the control of the coating thickness on the microstructured hydrogel and the amounts of inorganic substances within the hydrogel, raising expectations for the creation of a microenvironment that closely resembles that of a living body. Using laser 3D printing to construct microstructures resembling those found in bone, followed by conversion to inorganic composites to create bone-like inorganic biointerfaces, can be expected to pave the way for the development of bone models that mimic the in vivo environment. In the future, the research group aims to create even more precise organic−inorganic composite 3D models and develop bone models that replicate the microstructure found within bones. From these types of models, the research group aims to build 3D bone models that will contribute to regenerative medicine research, such as artificial bone marrow and bone substitute materials.

Iijima stated "The creation of complex structures was made possible by combining microfabrication using light with conversion to inorganic composites. We are attempting to apply this method to construct tissues such as bones, joints and bone marrow."

Journal Information

Publication: ACS Biomaterials Science & Engineering

Title: Microfabrication of Gelatin Methacrylate/Hydroxyapatite Composites by Utilizing Alternate Soaking Process

DOI: 10.1021/acsbiomaterials.3c01046

This article has been translated by JST with permission from The Science News Ltd. (https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.