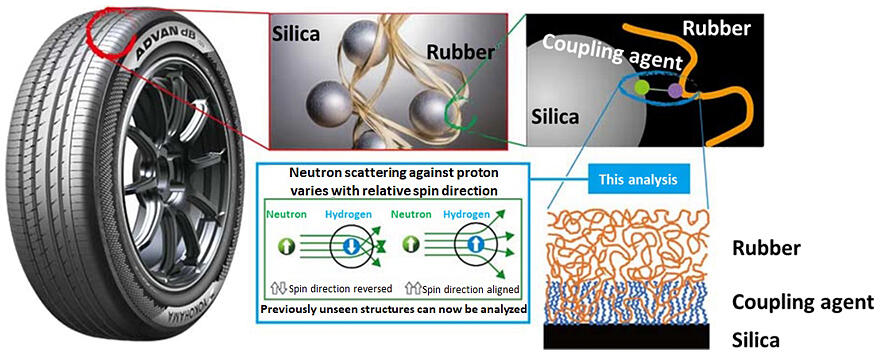

To create organic−inorganic hybrid materials, nano-level bonding is important between dissimilar materials. In automotive tires, silica nanoparticles are added to enhance the performance of rubber materials and coupling agents are added to strengthen the bond between rubber and silica. To understand the functioning of this coupling agent, it is necessary to observe the interface between different materials. However, previous methods did not allow direct observation. A joint research team led by Principal Researcher Takayuki Kumada of the J-PARC Center/Materials Sciences Research Center at the Japan Atomic Energy Agency (JAEA), Associate Professor Shotaro Nishitsuji of Yamagata University, Deputy Chief Engineer Kazuhiro Akutsu of the Comprehensive Research Organization for Science and Society, Professor Naoya Torikai of Mie University, Director Naoya Amino of The Yokohama Rubber Company and Professor Mikihito Takenaka of Kyoto University successfully observed the formation of a monolayer of the coupling agent at the interface between rubber and silica nanoparticles using spin-contrast-variation neutron reflectivity.

Kumada said "In this study, we found that the bonding method changes depending on the sample preparation method. We would like to improve the selection of silane coupling agents and manufacturing processes and further develop various hybrid materials." The results were published in The Journal of Physical Chemistry.

Provided by JAEA

Spin-contrast-variation neutron reflectivity is a method developed by JAEA in 2019 to precisely determine the structure of a material by identifying reflections in multiple planes via aligning the spins of hydrogen in the material in one direction when bombarding it with neutrons. Two types of samples were investigated in this study: simultaneously coated and sequentially coated. In the simultaneous coating sample, a mixed solution of rubber material (polybutadiene) and silane coupling agent was spin-coated on a silicon substrate rotating at a high speed, followed by heat treatment at 120℃. For sequentially coated samples, the silicon substrate was impregnated to a silane coupling agent solution and then spin-coated with a polybutadiene solution.

Analysis revealed that in the simultaneously coated sample, the silyl groups of the silane coupling agent form a monolayer linked to silica on the silicon substrate surface layer and alkyl groups on the opposite side of the silane coupling agent interpenetrate with polybutadiene chains. In contrast, in sequentially coated samples, the 20-nanometer-thick polybutadiene layer peeled off when the samples were cooled and polybutadiene chains were detached.

Journal Information

Publication: The Journal of Physical Chemistry C

Title: Interpenetration of Rubber and Silane Coupling Agent on an Inorganic Substrate Revealed by Spin-Contrast-Variation Neutron Reflectivity

DOI: 10.1021/acs.jpcc.4c00963

This article has been translated by JST with permission from The Science News Ltd. (https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.