Syringes offer the convenience of precisely delivering drugs to the optimal site and depth. Recently, needle-free syringes have been developed to address the fear of needles and the spread of infection associated with needle reuse. However, the liquid jets of commercially available needle-free syringes have a diffused shape and a large diameter at the tip. Thus, they have a large contact area with the skin and apply a large vertical force during injection, which can damage skin tissue.

A research group led by Professor Yoshiyuki Tagawa of the Graduate School of Tokyo University of Agriculture and Technology generated a focused liquid microjet with reduced vertical stress applied to the skin, using a jet-generating device, of which patent is owned by the university. In addition to reducing pain, the jet is expected to improve injection efficiency and controllability; however, it has not yet been put into practical use because the factors affecting penetration depth have not been fully clarified.

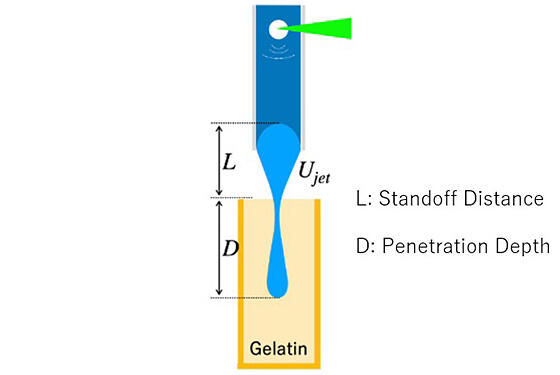

To solve this issue, the research group conducted experiments in which liquid jets were injected into a soft gelatin material that simulates skin by varying two parameters: the inner diameter of the jet injection tube and the distance between the liquid surface and the material. They found that the liquid penetration depth peaked at certain distances from the liquid surface, and the distances shifted further away as the inner diameter of the injection tube increased. Moreover, analysis of the jet velocities confirmed that the jet shape changed with the peak penetration depth and the maximum velocities. Accordingly, the research group introduced a new concept of the "jet pressure impulse," which is the jet force applied to unit area per unit time and found a correlation between the inner diameter of the jet injection tube and the liquid penetration depths.

These findings indicate that use of the jet pressure impulse as an indicator can contribute to the development of safer and less painful injectors. Moving forward, additional studies on the effects of the hardness of the material to be injected and the effectiveness of drugs are expected to pave the way for the practical use of this technology.