A research group of Okayama University and other institutions has developed an adhesive material for easy attachment and detachment to organs during surgery. Until now, the use of surgical sutures/stitches has been the primary method to "stick" organs together. However, the new material allows for quick attachment without requiring a high level of skill and allows detachment without damaging tissues when a large amount of water is poured. According to the research group, if the material is put into practical use, it will help shorten the duration of surgery and be useful for attachment and detachment of implantable devices for the next generation.

A research group led by Professor Takuya Matsumoto, who studies dentistry at the Department of Biomaterials, Graduate School of Medicine, Dentistry, and Pharmaceutical Sciences at Okayama University has been aiming to overcome the problems encountered when surgeons stick organs together during surgery and fix organs in place to ensure a clear view. The stitching technique is time-consuming and depends on the skill of the surgeon. To put the organ back to its original position, stitches have to be removed, and the procedure is complicated. Alternative methods to stitching include a tissue adhesive called "fibrin glue," which sticks biological tissues together; however, it takes time to polymerize for the sake of adhesion and the adhesive strength is weak.

To develop a new, highly useful adhesive material, Matsumoto and colleagues focused on the process of bone formation. During bone formation, chondrocytes are activated at the ends of bone, and spherical minerals in the vicinity attach to each other to form bone. In doing so, the minerals use the surrounding collagen tissue as "glue." Matsumoto approached the problem from a completely new angle and came up with the idea that bone components could be successfully used as an adhesive to stick organs, of which surfaces have an abundance of collagen.

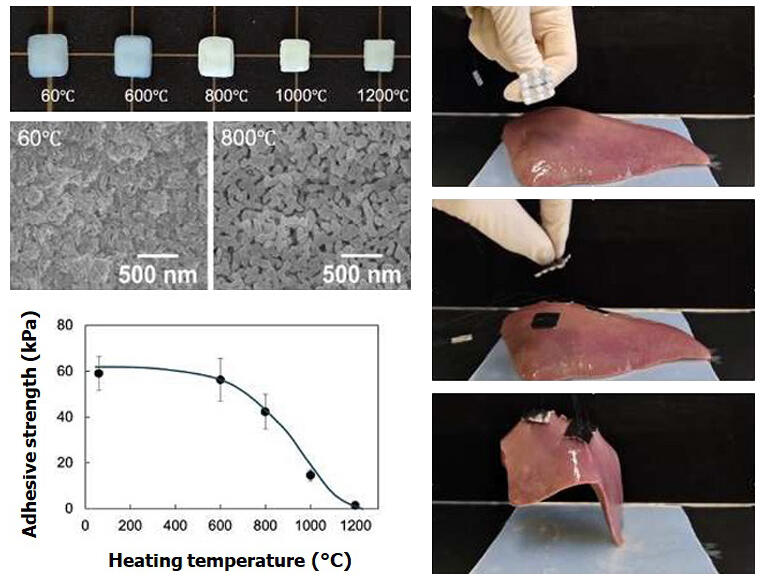

Calcium phosphate (hydroxyapatite), which is the main component of bones and teeth, was used in powder form to make fine nanoparticles, shaped, and then heated at high temperatures. This resulted in a plate with numerous "pores," which are small spaces between particles. The plate was developed as an inorganic ceramic adhesive with dimensions of approximately 5 mm per side. The mechanism is that calcium phosphate absorbs water from biological tissue, whereby collagen components of organs are attracted, and the organs are adhered. The organs were stuck together with only light pressure contact.

Provided by Professor Takuya Matsumoto

Although the material does not adhere to keratinized stratum corneum layers, which have little or no moisture, it adheres to the dermis and organs. This means that it is convenient to use in surgery. Matsumoto said "This works similarly to how rice fulfils the role of glue. When water is absent or there is too much of it, it is not adhesive; when there is a little water, it becomes viscous." The adhesion strength of the new material was found to be three times that of fibrin glue.

The density of calcium phosphate changes with the heating temperature during adhesive formation. The research group also showed that a certain adhesive strength was retained up to 600 ℃, but the adhesive strength decreased as the temperature was further increased. Porosity changes with the change in density. Porosity is responsible for controlling the amount of moisture and the adhesive strength. The observed temperature dependence can be used to produce the material with high and low adhesive strengths in a controlled manner. Furthermore, it will lose its adhesive strength and come off if a large amount of water is poured on it.

Porcine livers were used to test the effect of the adhesive on real organs. When nine pieces of adhesive were placed on the back of a hook-and-loop fastener, they stuck together and came off when exposed to water, fulfilling their role as adhesive. Furthermore, tissue specimens were examined for any changes, and the results showed that no organ injuries or adverse events occurred. The adhesive material also did not break down when washed for sterilization. The group will continue to conduct experiments to apply the proposed technology to humans.

Provided by Okayama University

In Sweden, an increasing number of people have microchips implanted in their bodies for payment and other purposes. Chips implanted in the body are small and must be fixed somehow so that they do not move inside the body. Matsumoto said, "As Neuralink, a company owned by Elon Musk (U.S. entrepreneur) and others, is developing brain implant devices. I think implantable devices in humans will become widespread in the future. If this adhesive material proves usable for humans, it can be used to facilitate device fixation and removal. Furthermore, I think it could be applied to microchips for pets."

This study was supported by a Grant-in-Aid for Scientific Research from the Japan Society for the Promotion of Science and by the Strategic Basic Research Program "CREST" from the Japan Science and Technology Agency (JST). The paper was published in the electronic edition of the American scientific journal Advanced Healthcare Materials on May 1, and the related press release was issued by Okayama University on May 24.

Original article was provided by the Science Portal and has been translated by Science Japan.