A research team led by Professor Ippei Maruyama of the University of Tokyo's Graduate School of Engineering, Engineer Koichiro Noritake and Group Manager Yoshinobu Hosoi of Rigaku, and Sub-leader Haruka Takahashi of Taiheiyo Consultant Co., Ltd has developed a simple device to evaluate the amount of fixed CO2 in materials made from cementitious materials such as concrete. The method of trapping CO2 in concrete is beginning to be used in various contexts as an important technology to achieve carbon neutrality; however, measuring the amount of fixed CO2 has been time-consuming and labor-intensive. It is expected that the development of this device will lead to the appropriate implementation of carbon taxes and emission trading. The results are published in Journal of Advanced Concrete Technology.

Provided by the University of Tokyo

Currently, 4.5 billion tons of cement are produced annually worldwide (as of 2015), and approximately 800 kg of CO2 is emitted to produce one ton of cement. Fifty percent of this emission is due to the decomposition of calcium carbonate to obtain calcium, and the rest is owing to fuels involved in transportation and calcination. It is estimated that 5%-8% of CO2 emissions from human activities to date have originated from cement production. As a measure to reduce emissions, mixing calcium carbonate in concrete and precipitating it through reactions for use in a long period of time is considered effective. It is being evaluated and studied as a method to offset CO2 emissions.

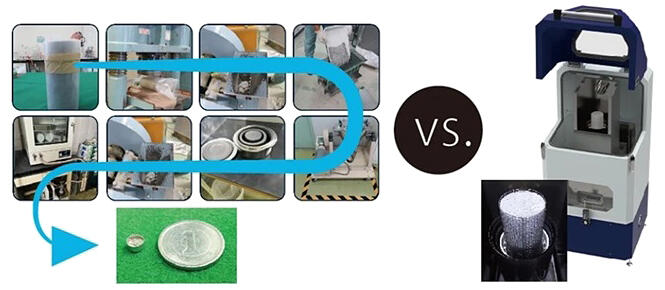

Meanwhile, concrete is a composite material comprised of coarse aggregates, and fine aggregates, cement, water, and admixture material. It is made of various materials of different dimensions. In the construction field, a typical concrete specimen for use in buildings has a diameter of 100 mm and a height of 200 mm, given that the coarse aggregate of the constituent materials is as large as 20 mm. When measuring the amount of CO2 fixed in it, it is necessary to perform a complex and time-consuming process to crush all these large specimens for preventing them from reacting with air and making them uniform.

Therefore, research and development was conducted to develop a device that can drastically solve this issue. For this purpose, the University of Tokyo was in charge of the concept of the device and items required for the device, Rigaku was in charge of the actual device development, and the University of Tokyo and Taiheiyo Consultant were in charge of the verification of the fabricated device. The newly developed device can measure the amount of CO2 contained in a concrete specimen by placing and heating a specimen of typical dimensions without pulverizing it and measuring the CO2 concentration in the gas generated by heating. The results measured using the equipment are in good agreement with the theoretical values calculated from the material composition ratio when the concrete was mixed and respective CO2 amount in the constituent materials.

Specifically, the concrete specimens were divided into 16 sample groups for comparison of the following cases: pulverization performed by the conventional method to measure the CO2 amount, theoretical values calculated from the constituent materials at the time of fabrication, and the results of measurements using the present measuring device. The conventional method shows a large variation, while the results obtained from the present device are closer to the theoretical values. This result indicates that the amount of CO2 fixed in a representative sample can be measured efficiently and with high accuracy, not only when CO2 is uniformly dispersed in the specimen, but also when the amount of fixed CO2 varies between the specimens.

After confirming the applicability to concrete samples and identification of the measurable range, it is expected that the equipment will be marketed and will contribute to healthy emission trading and other activities in the concrete sector.

Journal Information

Publication: Journal of Advanced Concrete Technology

Title: Development of a Large-scale Thermogravimetry and Gas Analyzer for Determining Carbon in Concrete

DOI: 10.3151/jact.22.383

This article has been translated by JST with permission from The Science News Ltd. (https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.