Professor Yoshihito Kawamura of Kumamoto University's Magnesium Research Center and his team developed a new magnesium alloy that exhibits flame resistance and yield strength 1.7 times higher than conventional general-purpose high-strength magnesium alloys. Kawamura stated, "In this research, we found that kink strengthening (a strengthening method that reduces the probability of deformity by bending the crystal) can be applied even if hard layers are dispersed throughout the material. As this method can be extended to other metallic materials and ceramics, we would like to develop this finding as a new academic field."

Provided by Kumamoto University

Lightweight and strong materials are important because achieving weight reduction in transportation equipment directly correlates to a reduction in energy costs. Magnesium has attracted significant attention being the lightest practical metal. There is fierce competition around the world to develop high-strength magnesium alloys. However, until now, its drawbacks are that its mechanical strength is lower than that of aluminum alloys and it is flammable.

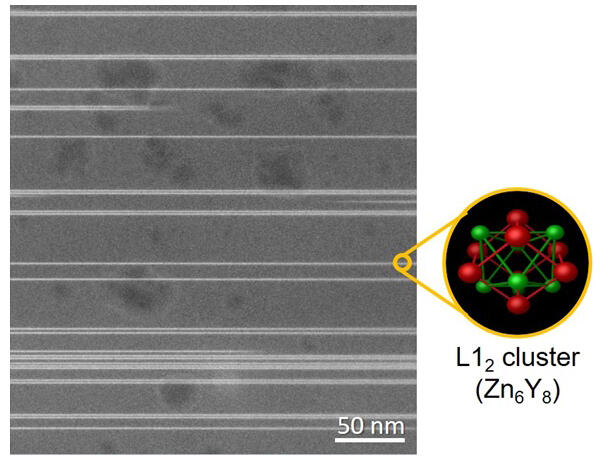

In the 2000s, Kawamura and his team discovered a new method for material strengthening called kink strengthening, the first discovery of its kind in half a century. However, alloys to which kink strengthening could be applied were limited to KUMADAI heat-resistant magnesium alloys with a long-period stacking structure. This long-period stacking structure has a dense hard and soft layered structure comprising periodically stacked hard cluster-arranged layers (CAL) of approximately 1 nm thickness (four atoms thick) and soft magnesium layers of less than 1 nm thickness.

After four years of trial-and-error investigations of different alloy compositions and manufacturing processes, the research group succeeded in developing a magnesium alloy in which CAL is distributed sparsely throughout the material. This alloy has an average CAL interval of 12 nm. Further, the research group discovered that kink strengthening can be applied even when the average CAL interval is more than 12 times wider than this alloy's CAL. Despite the fact that it has only half the alloy additive content compared with KUMADAI heat-resistant magnesium alloys, the developed magnesium alloy was reinforced with a low extrusion ratio of 6, demonstrating an extremely high yield strength of 418 MPa, which is more than 1.7 times that of conventional high-strength magnesium alloy extrusions. Furthermore, the alloy is flame resistant and has an ignition temperature of 770℃. This hard and soft layered structure is referred to as a mille-feuille structure, named after the mille-feuille cake. The developed alloy was named the "mille-feuille-type magnesium alloy."

Kawamura added, "In the future, by accelerating joint research into practical applications, we would like to expand this finding to high-end applications in fields such as the space and aviation fields. We would also like to establish a theory for kink reinforcement by clarifying, through experiments and computations, the largest possible interval between CALs where kink reinforcement is applicable."

Journal Information

Publication: Journal of Alloys and Compounds

Title: Kink bands and strengthening of millefeuille-structured magnesium alloys by cluster-arranged nanoplates (CANaPs): The case of Mg-0.4Zn-1.0Y alloy

DOI: 10.1016/j.jallcom.2022.168607

This article has been translated by JST with permission from The Science News Ltd. (https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.