Professor Masashi Miura of the Graduate School of Science and Technology at Seikei University, together with Honorary and Institute Professor Hideo Hosono and Professor Hidenori Hiramatsu of Tokyo Institute of Technology, has fabricated an iron-based superconducting SmFeAsO1-xHx thin film through a new material design guideline, namely the integration of carrier density control and flux pinning point control. The thin film achieved the highest critical current density among iron-based superconducting materials under a high magnetic field of 25 Tesla at 4.15 K. Moreover, this world's highest critical current density was achieved with different types of superconducting materials using the material design guideline, confirming its validity. The results were published in Nature Materials.

Provided by Seikei University

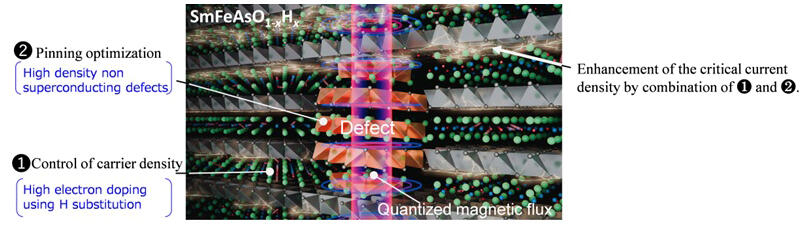

The range of practical application of the critical current density is indicated by the region determined by three parameters: critical temperature, irreversible magnetic field, and critical current density. Widening the region thus determined will broaden the range of applications. A major challenge is to dramatically increase the critical current density in magnetic fields for many superconducting materials. It is known from past research that the introduction of a flux pinning point (nonsuperconducting phase), which suppresses the motion of quantized magnetic flux entering a superconducting body, is effective in improving the critical current density.

The research group used thin films made of high-temperature superconducting materials comprising copper oxide to clarify that the improvement in the depairing current density, which is the theoretical limit of the critical current density, has a significant effect on the improvement of the critical current density. Recent studies have also revealed that controlling tuning parameters, such as carrier density, chemical pressure, and strain, is the key to improving the depairing current density.

In response to this, they aimed to dramatically improve the critical current density in a magnetic field through the new material design guideline, namely: "the integration of carrier density control and flux pinning point control," in which the carrier (electron) density is controlled by adjusting the extent of hydrogen injection in SmFeAsO1-xHx thin films and then introducing a magnetic flux pinning point. By selecting hydrogen instead of fluorine as the injecting element, they succeeded in injecting carriers (electrons) in the iron-based superconducting thin films by a factor of three or more and dramatically improving the depairing current density and critical current density (without external magnetic field). Furthermore, as a result of successfully introducing high-density flux pinning points by proton beam irradiation, the world's highest critical current density among iron-based superconducting materials was successfully achieved.

The thin films achieved the highest in-field critical current density of any iron-based superconducting material, even under a high magnetic field of 25 Tesla at the boiling temperature of liquid helium (4.15 K). This property is comparable to that of YBa2Cu3Oy thin films, a high-temperature superconducting material made of copper oxide with the highest critical current density among superconducting materials. Moreover, when other iron-based and yttrium-based superconducting thin films were tuned according to this design guideline, the depairing current density and critical current density in magnetic fields were improved. The newly developed thin films are expected to be used as superconducting materials in high magnetic fields, such as those used in large hadron collider accelerators, nuclear fusion power generation, nuclear magnetic resonance devices for molecular structure analysis, research MRI devices, and linear motor cars.

Journal Information

Publication: Nature Materials

Title: Quadrupling the depairing current density in the iron-based superconductor SmFeAsO1-xHx

DOI: 10.1038/s41563-024-01952-7

This article has been translated by JST with permission from The Science News Ltd. (https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.