Sustainable aviation fuel, or SAF, is a jet fuel made from renewable or waste materials, reducing greenhouse gas (GHG) emissions compared with fossil fuels. The Green Power Development Corporation of Japan succeeded in producing 100% biomass-derived SAF (neat SAF) for the first time in the world from nonstandard inedible coconut oils using a catalyst developed in collaboration with the Tokyo University of Agriculture and Technology and HighChem. Neat SAF has been approved as meeting the international quality standards of ASTM, a U.S. standards organization. The results of this project, which is run by the New Energy and Industrial Technology Development Organization (NEDO) have demonstrated the possibility of the mass production of SAF, which is excellent in terms of production efficiency, cost, and environment, and have made notable progress toward a scale-up demonstration.

Masato Fujii (General Manager of the Green SAF Division and Strategic Project Director at the Green Power Development Corporation of Japan), explained, "From the beginning, our goal for SAF was to use vegetable oils that do not compete with food, and after exploring various raw materials, we decided to use nonstandard inedible coconuts." He also stated that the market for waste cooking oil, which is now being used as a substitute for petroleum-based fuels, is expected to become more competitive in the future due to its high value in SAF, that finding new raw materials for SAF has become an important issue, and that inedible coconuts are of use as such a raw material.

Provided by NEDO

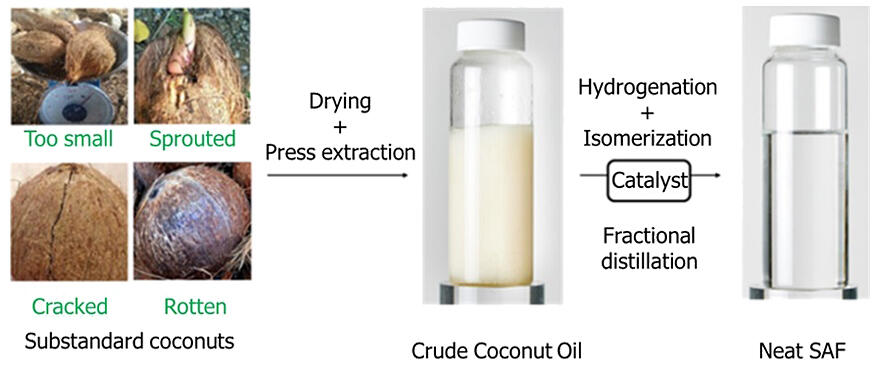

Crude coconut oil (CCO) extracted from coconuts is advantageous for use as an SAF raw material because the number of carbon atoms in fatty acids in it is similar to that in hydrocarbons that make up jet fuel. The advantage of using CCO is that less hydrogen is required to separate hydrocarbons, which is necessary for processing the oil into SAF fuel, thereby reducing GHG emissions. The entire coconut, from its outermost shell to the inner seeds, can be used for power generation and fuel production and thus has great potential for GHG reduction. Of this, the pulpy part in the seed (approximately30% total) is used for SAF preparation. The pulp is pressed to make CCO, which is then catalytically hydrogenated to produce hydrocarbons. The manufacturing process involves distilling the resulting liquid to separate hydrocarbons and extract neat SAF.

The company also established a standard for inedible coconuts (small, sprouted, cracked, and rotten) so as not to compete with edible coconuts. In March this year, this standard was registered on the positive list of the "Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA)." This scheme is a system for managing GHG emission reduction in international aviation formulated by the International Civil Aviation Organization (ICAO). The standard that the company established was recognized as an internationally accepted standard. The catalyst required for the production of neat SAF was developed jointly with the Tokyo University of Agriculture and Technology and HighChem. In June of this year, it was confirmed that this catalytic manufacturing technology complies with one of the eight standards established by ASTM and was recognized as a manufacturing technology that complies with international standards.

Currently, 70 million tons of coconut are produced annually worldwide, of which it is estimated that 30% or approximately 20 million tons is nonstandard. The company's business model for nonstandard coconuts involves the local procurement of nonstandard coconuts from Indonesia, the Philippines, and other major coconut-producing countries as raw materials and local production of CCO for export to Japan. Japan manufactures neat SAF from imported CCO and sells it to SAF-manufacturing companies, which then make jet fuel mixed with neat SAF for sale and distribution to domestic and foreign airlines.

"The cost of raw materials for SAF is currently 300-400 yen per liter, and there is a need to develop raw materials that are cheaper than this. We plan to start operations at our CCO production plant in Indonesia in 2027 and to have a commercial plant operational with an annual production capacity of 80,000-100,000 tons of neat SAF by 2030. We will work to achieve a cost that is competitive with other raw materials by then, but I don't think it will be easy, and I think that government support will be necessary at the beginning of the business," said Mr. Fujii, who is looking forward to the commercialization of the product.

This article has been translated by JST with permission from The Science News Ltd. (https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.