Expectations are growing for new devices such as electronic fibers and electronic skin, which can be used to monitor health conditions while being worn. A highly sensitive strain sensor is essential for the development of such devices. Sensors that utilize the piezoresistive effect of materials have the advantages of high stability, high durability, and low cost. In particular, semiconductor materials, which exhibit a piezoresistive effect several tens of times that of pure metals, can be applied to the microelectromechanical system (MEMS) technology. They are therefore expected to be used to create ultrasensitive materials that can detect extremely small strains, such as pulse and heartbeat.

A research group comprising Program-specific Assistant Professor Yinli Wang at Kyoto University (graduate student at the Graduate School of Engineering, Tohoku University at the time of the research), Professor Yuji Sutou at the Graduate School of Engineering (also at AIMR), and Professor Fumio Narita at the Graduate School of Environmental Studies at Tohoku University measured the piezoresistive effect of a thin film of amorphous Cr2Ge2Te6 semiconductor (CrGT) deposited on a flexible polyimide substrate. The research group observed an extremely large gauge factor of 60,000, discovering that the material exhibits sensitivity several hundred times higher than other semiconductor materials. It was found that the huge change in resistance observed for this thin film is caused by the creation and propagation of cracks in the CrGT thin film due to strain. A distinctive resistance change in response to a pulse was confirmed using a simple strain sensor using this thin film. CrGT thin films can be deposited on flexible substrates via general sputtering methods and do not require subsequent heat treatment. They are expected to be utilized as ultrasensitive strain sensor materials that can be applied to various flexible substrates. The results are published in Materials Horizons.

Provided by Tohoku University

In this research, a mechanical and electrical measurement system made up of a tensile tester, a semiconductor measuring instrument, a laser microscope, and a Raman spectroscope was constructed to attempt to clarify the mechanism of the resistance change of amorphous CrGT thin film sample deposited on polyimide due to strain loading and unloading. The results show that the main cause of the huge resistance change is the creation and propagation of cracks due to tensile strain. The researchers also found that within the strain region of the elastic deformation range of polyimide, the significant resistance value increase is caused by cracks created in the CrGT thin film due to strain loading; however, the cracks completely close when the strain is unloaded, and the resistance value returns to its initial value. It was also found that repeated use is possible within that strain range. This indicates that huge and reversible resistance changes beyond the limits of existing materials can be achieved via the creation and opening/closing of cracks in amorphous CrGT thin films.

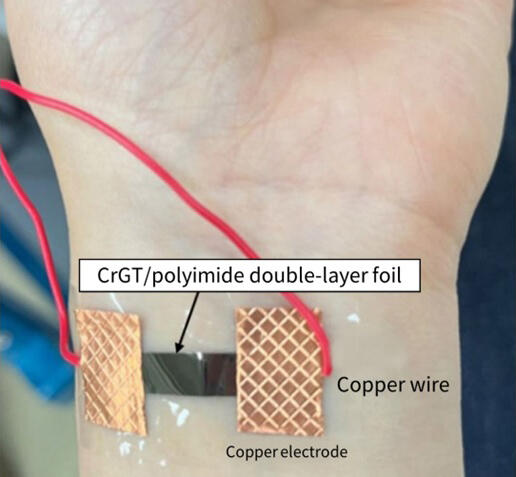

In this study, the researchers also proposed a simple strain sensor in which an amorphous CrGT thin film is disposed on polyimide. They demonstrated that it can clearly detect arterial pulse waves, showing its potential for use in health monitoring systems. The proposed new thin film is expected to be applied to a wide variety of sensors, including health diagnostic systems, because of its ability to achieve ultrahigh sensitivity with a simple device structure. In addition to the quantitative evaluation of cracks in amorphous CrGT thin films and verification of their durability, the research group will focus on piezoresistive effects in brittle semiconductor thin films other than CrGT.

This article has been translated by JST with permission from The Science News Ltd. (https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.