On October 4, a research group led by Senior Researcher Satoshi Wakai of the Institute for Extra-cutting-edge Science and Technology Avant-garde Research, Japan Agency for Marine-Earth Science and Technology (JAMSTEC), in collaboration with the National Institute for Materials Science (NIMS), the Central Research Institute of Electric Power Industry (CRIEPI), Nippon Steel Corporation, and the Japan Atomic Energy Agency (JAEA), has announced that they started the development of diagnostic technologies for metal corrosion caused by microorganisms. The technologies to be developed are intended to cover a wide range of applications from use in the decommissioning environment of the Fukushima Daiichi Nuclear Power Station to in the general industry environment. During the research period that will last until the end of fiscal year 2026, they aim to develop a prototype simple diagnostic kit for on-site use establish a diagnostic protocol within 1−3 years after the aforementioned period ends.

Provided by JAMSTEC

Microbial corrosion is a phenomenon in which metallic materials are corroded at an accelerated rate due to the presence and action of microorganisms. Causal microorganisms have been found in recent years. However, no diagnostic technologies are available for metal corrosion, and the affected materials are repaired after corrosion has occurred. As a result, microbial corrosion causes environmental pollution and significant economic losses, estimated to amount to about 6.6 trillion yen annually in Japan.

The research is conducted under the Problem-Solving-type Decommissioning Research Program of the "Center of World Intelligence Project for Nuclear Science and Technology and Human Resource Development" commissioned by the Ministry of Education, Culture, Sports, Science and Technology. The goal is to consolidate the constituent technologies to JAMSTEC after they are advanced by participating research institutions and develop various diagnostic technologies for use in different settings. During the course of the research, knowledge related to the prevention of or countermeasures for metal corrosion is also expected to be accumulated through screening. The developed technologies are expected to be necessary and used for the safe decommissioning of the Fukushima Daiichi Nuclear Power Station (1F) and to contribute to the preservation of facilities such as petroleum and chemical plants and public facilities around us.

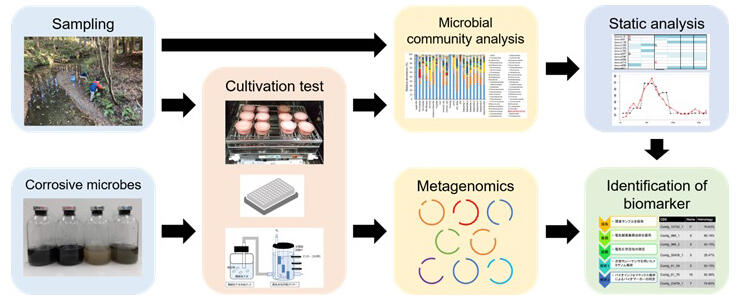

Previously, JAMSTEC has succeeded in capturing changes in microbial populations during microbial corrosion by evaluating microorganisms as a population. In 2022, they revealed that sulfate-reducing bacteria, the presence of which had been considered to be an indicator of microbial corrosion, were found minimally in the initial process. Instead, the abundance of iron-oxidizing bacteria was shown to be high and change over the corrosion process. They also worked on developing constituent technologies, including methods for specific accumulation of highly corrosive microorganisms, isolation of novel corrosive microorganisms, and identification of biomarkers.

With the aim of developing various diagnostic technologies for a wide range of on-site applications from ultra-sensitive diagnosis to simple diagnosis, JAMSTEC is collaborating with the NIMS, the CRIEPI, Nippon Steel Corporation, and the JAEA. Under this collaborative scheme, the NIMS is developing a corrosion assay system to test multiple specimens simultaneously, the CRIEPI is conducting experiments using a high corrosion test reactor that simulates a 1F environment, Nippon Steel Corporation is conducting statistical analysis of data on metal corrosion and community structure of microbial populations, and the JAEA is conducting corrosion tests under radiation environments.

Wakai said, "Microbial corrosion is involved in many areas, in which a common issue is structural integrity. It is important to understand the deterioration phenomena, such as corrosion, to deal with the ever-changing environment. Through our research, we want to develop technologies for demonstrating the integrity and safety of the decommissioning environment with scientific evidence to rationally proceed with decommissioning rather than exposing the risk of microbial corrosion in the 1F environment. If we find a risk of microbial corrosion, we will need to take proactive measures, so I think it is important to first investigate the risk with concrete evidence."

This article has been translated by JST with permission from The Science News Ltd. (https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.