A research team led by Associate Professor Toshihiro Isobe of the School of Materials and Chemical Technology and Associate Professor Manabu Fujii of the School of Environment and Society at the Institute of Science Tokyo has developed a system that can reduce perfluoroalkyl and polyfluoroalkyl compound (PFAS) levels below environmental standards. PFAS has been widely used in various applications, such as surfactants, semiconductor antireflectants, water repellents, and polymer processing aids. However, due to its resistance to decomposition in the natural environment, its high persistence, and concerns over its impact on human health and ecosystems, its production and use are increasingly regulated in Japan and abroad. According to a survey conducted by the Ministry of the Environment and Ministry of Land, Infrastructure, Transport and Tourism, the concentrations of PFOS and PFOA among PFAS have exceeded the provisional target values at 111 locations in rivers and groundwater in 16 prefectures across Japan, with 74 of these cases being observed in groundwater.

Provided by Science Tokyo

Currently, research and development on the use of activated carbon to remove PFAS via adsorption are in progress. However, secondary issues, such as leaching from activated carbon stored after treatment into the environment, have been reported. Meanwhile, membrane separation technologies, including reverse osmosis membranes (RO membranes), are being considered for PFAS removal, but their running costs are high.

In these developments, the research group focused on the membrane distillation method. Membrane distillation is a water treatment technology that utilizes the difference in the boiling points between water and the material being separated. In this method, contaminated water is brought into contact with the membrane and heated. Water vapor passes are allowed to permeate through the membrane, but solutes or solids are not. Compared to water purification via distillation, this method can operate at lower temperatures and exhibit the same level of high-water purification performance, and it requires less power than RO. Furthermore, although few studies have used membrane distillation for PFAS removal, no separation membranes specifically developed for PFAS removal have been reported.

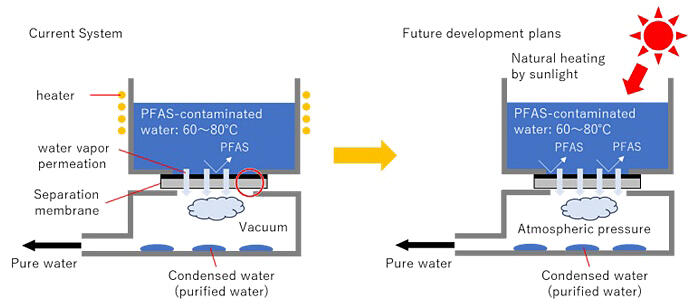

In response to this, the group worked on developing a separation membrane for membrane distillation (a carbon membrane) made of carbon, which was resistant to heat and salt damage. The developed carbon membrane has a pore size of approximately 0.1 micron and a water contact angle of approximately 117° and exhibits porosity, water repellency, and high heat resistance, making it a suitable separation membrane for membrane distillation. When pseudo-contaminated water (PFOS concentration: approximately 500 ng/L) was brought into contact with the developed carbon membrane and heated at approximately 80℃, it was confirmed that evaporated water permeated through the membrane. When the permeated liquid was analyzed via liquid chromatography-mass spectrometry, its impurity level was below the measurement limit (approximately 3 ng/L). This is below the water quality control target (50 ng/L) and U.S. environmental standard (4 ng/L). Furthermore, the pore size can be controlled by regulating the carbon membrane production conditions, and the pore size is correlated to the treatment amount per unit time. The carbon membranes used in this study were made from glucose, but they could be made from commercially available edible sugar. The team plans to work on purifying contaminated water in actual soil and to develop technology to increase the amount of water treated per unit of time. The current system uses a heater to heat pseudo-contaminated water and a vacuum pump to promote water evaporation. In the future, they aim to switch to a heating method that uses sunlight and expand the proposed system to a completely electric-power-free system that does not use heaters or vacuum pumps.

This article has been translated by JST with permission from The Science News Ltd. (https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.