The Kyoto University CiRA Foundation (CiRA Foundation) began operation of a facility in April to manufacture induced pluripotent stem cells (iPS cells) derived from a patient's own cells that can be transplanted without immune rejection. The facility will reduce costs by fully automating cell manufacturing in closed culture systems. Clinical research and trials in humans could begin as early as 2028. The Foundation aims to eventually provide "my iPS cells" for therapeutic use at approximately 1 million yen per donor, focusing primarily on the treatment of intractable diseases where immunosuppressants cannot be used and rare pediatric diseases.

(located within Nakanoshima Qross in Kita Ward, Osaka City)

While iPS cells show promise for use in regenerative medicine, cell transplantation therapy, and drug development, the current manufacturing process relies on manual labor, making it time-consuming and costly. The CiRA Foundation was established in 2019 with the philosophy of " delivering optimal iPS cell technology at a reasonable price."

The Foundation previously provided clinical research-grade iPS cells manufactured from the blood of healthy volunteers with HLA (Human Leukocyte Antigen) types that are less likely to cause immune rejection, as well as iPS cells with reduced risk of immune response through genome editing technology.

From an immune rejection perspective, creating iPS cells from a patient's own cells for "autologous transplantation" is optimal. However, creating new iPS cells from a patient currently requires a team of more than four people working for several months at a cost of tens of millions of yen. To address these time and cost challenges, the Foundation launched the "my iPS Cell Project." The aim of the project is to "establish a facility capable of manufacturing cells for 1,000 people annually and providing them at approximately 1 million yen per person, with the goal of practical implementation around March 2025."

(located within Nakanoshima Qross in Kita Ward, Osaka City)

According to Masayoshi Tsukahara, Executive Director of the Research and Development Center at the CiRA Foundation, closed-type culture systems and full automation are necessary to solve the challenges of time and cost. Closed systems allow for simplified worker garbing procedures. Eliminating manual labor through automation reduces the risk of contamination and human errors such as mishandling. It also enables small-lot, multi-product manufacturing. Tsukahara said, "While I acknowledge the benefits of manual work, to industrialize iPS cell manufacturing, it's necessary to quantify and automate what skilled workers have been doing so that anyone can do it."

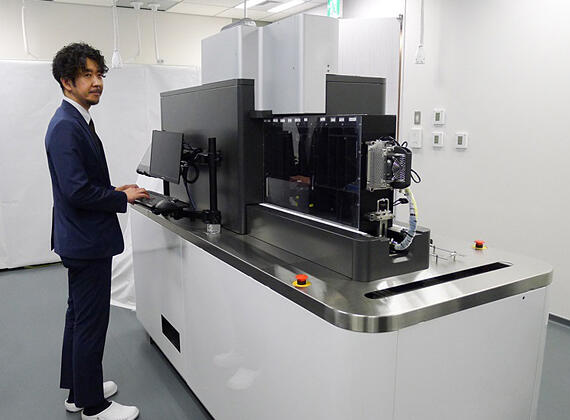

The facility will initially use 13 automated culture devices designed for CAR-T cell cancer treatment to manufacture iPS cell stocks from blood that can be cryopreserved. The Foundation is also working with Canon and Canon Medical Systems to develop new devices for automated culture.

(located within Nakanoshima Qross in Kita Ward, Osaka City)

Even after a patient's iPS cells are created, they must be differentiated into cells that can be used in the organs and tissues requiring treatment, and their safety must be confirmed, including checking that they do not become cancerous. Cell differentiation and monitoring will be handled by the "my iPS Research Institute," which was established before the manufacturing facility in Nakanoshima Qross in Kita Ward, Osaka City. The institute is currently conducting research on methods to differentiate stored iPS cells into specific cell types.

(located within Nakanoshima Qross in Kita Ward, Osaka City)

The manufacturing facility includes exhibition space about the history, manufacturing, and utilization of iPS cells, and visitors can observe the clinical grade iPS cell manufacturing facility through glass windows. The facility underwent a compliance inspection by the Pharmaceuticals and Medical Devices Agency (PMDA) on April 10. It is planned to be operated as a clinical-grade autologous iPS cell manufacturing facility under the Act on the Safety of Regenerative Medicine. The Foundation plans to hold an opening ceremony on June 20, inviting Tadashi Yanai, Chairman and President of Fast Retailing, which operates the Uniqlo chain, who donated 4.5 billion yen to the my iPS Cell Project.

Original article was provided by the Science Portal and has been translated by Science Japan.