The National Institute for Materials Science (NIMS) has demonstrated a principle that further improves recording efficiency in "heat-assisted magnetic recording (HAMR)" technology for hard disk drives (HDDs) by localized laser heating. The principle utilizes temperature differences within the recording medium for the improvement of recording efficiency. By placing a layer of manganese-platinum beneath a layer of iron-platinum, they harnessed previously unused heat to create a "spin torque" that changes the direction of magnetization. This technology is expected to contribute to increasing HDD capacity and reducing power consumption in the future.

Provided by Senior Researcher Shinji Isogami, NIMS

HDDs are used as information storage media in all computers and data centers. They consist of magnetic substances thinly spread in film form on hard disks. The electrons in these thin film materials possess magnetic properties (spin) that align in a specific direction due to temperature differences or electric currents, and this orientation is recorded as information. The image is of tiny magnets arranged in small sections on the disk, with each section's orientation (whether North or South pole) recorded as 0 or 1 information.

Provided by Senior Researcher Shinji Isogami, NIMS

Research has progressed toward increasing recording density, as packing information into smaller sections allows HDDs to store more data. However, as recording density increases, spins begin to fluctuate even at room temperature, making information writing more difficult.

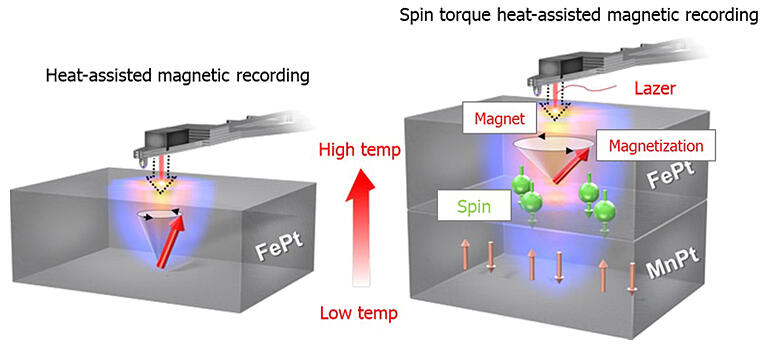

As a solution, heat-assisted magnetic recording using localized laser heating to write to iron-platinum thin films was proposed and commercialized by Seagate Technology, a U.S. HDD manufacturer, in 2020. Mass production began in 2024. However, the repeated rapid heating consumes significant energy for data writing.

Provided by Senior Researcher Shinji Isogami, NIMS

Senior Researcher Shinji Isogami who studies Magnetic Engineering at NIMS's Research Center for Magnetic and Spintronic Materials and his colleagues focused on the temperature difference that occurs between the front and back sides of the medium during laser irradiation. They considered that by using manganese-platinum thin films, which have recently gained attention for generating spin, they might be able to utilize heat that wasn't being used for recording.

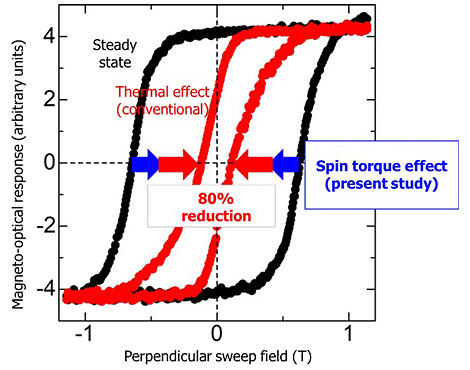

When they inserted a "manganese-platinum antiferromagnetic layer" beneath the iron-platinum recording layer, the force maintaining magnetism was reduced by up to 80% compared to conventional heat-assisted magnetic recording, making writing easier. They also found that 35% of this reduction was due to spin torque created by injecting, into the iron-platinum layer, spins generated by temperature differences in the manganese-platinum layer. This demonstrates that the thermal energy required for writing can be reduced.

Provided by Senior Researcher Shinji Isogami, NIMS

Isogami stated that this "spin torque heat-assisted magnetic recording is expected to improve HDD durability and reliability." Future challenges include controlling the increased thickness of the film resulting from layering iron-platinum and manganese-platinum.

The research was supported by the Japan Society for the Promotion of Science's Grants-in-Aid for Scientific Research and the Japan Science and Technology Agency (JST)'s Strategic Basic Research Programs, conducted in collaboration with Seagate. The research results are published in the electronic version of the scientific journal Acta Materialia on January 13.

Original article was provided by the Science Portal and has been translated by Science Japan.