Professor Hitoshi Soyama, Assistant Professor Kousuke Hiromori, and Professor Naomi Shibasaki-Kitakawa from the Graduate School of Engineering at Tohoku University announced that they have demonstrated technology to extract caffeic acid from coffee grounds while simultaneously defibrating coffee bean cellulose into micro-order fibers using hydrodynamic cavitation. This technology is expected to be applicable to various food wastes and could contribute to the extraction of valuable substances and the value-added utilization of biomass. The valve-type hydrodynamic cavitation device developed in this study is currently under patent application. The researchers' results were published in the international academic journal Ultrasonics Sonochemistry on April 25.

Provided by Tohoku University

More than 10 million tons of coffee beans are produced annually, generating large amounts of spent grounds after extraction. These grounds contain valuable substances including caffeic acid, which is used in anticancer drugs, but no industrial extraction method has been established, and most grounds are discarded as waste.

The researchers focused on the hydrodynamic cavitation phenomenon. Cavitation is a phenomenon that occurs inside pumps and valves in factory equipment, generating strong, localized impact forces that can deform even metals when bubbles collapse. While this was traditionally considered harmful to equipment, recent research has been advancing the utilization of this impact force, with hydrodynamic cavitation showing particularly high energy efficiency.

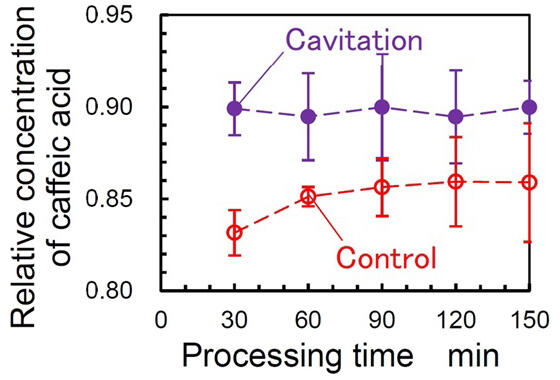

The researchers investigated whether it would be possible to efficiently extract caffeic acid from coffee grounds through the chemical effects of hydrodynamic cavitation, while simultaneously defibrating the fiber components in coffee grounds into micro-order cellulose fibers that could be used for industrial materials through its physical effects. Using a Venturi tube-type hydrodynamic cavitation device and valve-type hydrodynamic cavitation device developed by Soyama's team, they generated and collapsed fine bubbles in an ethanol aqueous solution mixed with coffee grounds (unused), applying strong impact treatment. Subsequently, Hiromori and Shibasaki-Kitakawa measured caffeic acid concentrations and produced freeze-dried samples of the aqueous solution. Soyama used the samples to analyze cellulose fiber structures through scanning electron microscopy observation.

The extraction amount was compared with conventional Soxhlet extraction using 60 vol% isopropanol aqueous solution at 95℃. As a result, the researchers successfully improved cavitation impact energy by 20 times through the optimization of pressure in the cavitation collapse field. They confirmed that significantly more caffeic acid could be extracted and that defibration into micro-order cellulose fibers was possible.

Soyama commented: "Previously, when processing biomass with cavitation, it had to be finely ground and classified through sieves and could only be processed at concentrations below 1 wt%. By improving the pump and components for cavitation generation, we made it possible to process coffee grounds at high concentrations of 20 wt% or more without grinding."

Journal Information

Publication: Ultrasonics Sonochemistry

Title: Simultaneous extraction of caffeic acid and production of cellulose microfibrils from coffee grounds using hydrodynamic cavitation in a Venturi tube

DOI: 10.1016/j.ultsonch.2025.107370

This article has been translated by JST with permission from The Science News Ltd. (https://sci-news.co.jp/). Unauthorized reproduction of the article and photographs is prohibited.