Special Professor Yoshihiro Ohba and Professor Hidemitsu Furukawa, members of the Academic Assembly of Yamagata University, are taking on the challenge of developing soft robots that will change the conventional idea of robots. They are carrying out initiatives that make the best possible use of the functions of organic materials, and, at the same time, bringing each outcome together to establish the concept of "soft matter robotics," which in the near future will become a new key industry. Careful consideration is being given to the process of developing soft robots so that they do not compromise the natural environment, or the ability of future generations to maintain sustainable communities. Their aim is to create a one of a kind, world first global research hub at Yamagata University that will also involve local institutions and industry.

Representative for "soft mechanics" projects, and Yoshihiro Ohba (right), Special Professor, OPERA Consortium Manager since 2016, Academic Assembly, Yamagata University

Working towards a hub for cutting-edge research and development in Yonezawa, the birthplace of artificial silk

Yamagata University's Faculty of Engineering is located in Yonezawa City, known as the birthplace of rayon (artificial silk), which was first developed in Japan by Itsuzo Hata in 1915. In 2016, Special Professor Yoshihiro Ohba, a member of the Academic Assembly of Yamagata University who works as the Consortium Manager in OPERA's Soft Matter Robotics Consortium (SOFUMO) , established a world-leading education and research base for organic material systems in Yamagata University, which inherited Itsuzo Hata's entrepreneurial spirit. "When we talk about organic material systems, we are referring to a concept that embraces every process, from basic research to social implementation. We aim to bring about technological innovation in each organic materials process and realize a society in which everyone makes everyone else happy."

Yamagata University successively established a base for organic electronics research and a hub for applied research in 2011, a place for demonstration experiments with to the goal of commercialization in 2013, and a hub for integrated and interdisciplinary research in 2015. Speaking about the transformation so far, Special Professor Ohba says, "In 2016, we established a new Graduate School of Organic Materials Science, which has become a great hub where around 500 people, including university faculty members, students, and engineers from companies, participate in organic material systems."

Setting up projects by calculating backwards from the end goal,and working towards industrial application by combining fundamental technologies

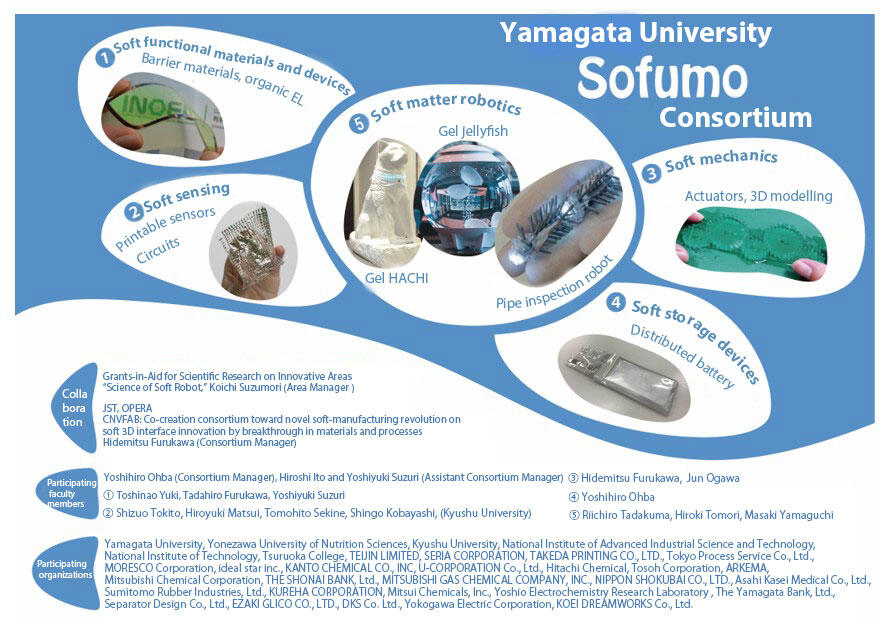

In 2016, when facilities were readied, JST started OPERA, aiming to cultivate new key industries through industry-academia collaboration. As many as 22 companies (26 as of January 2021) participated in the program under Yamagata University, refining fundamental technologies in the areas of soft functional materials and devices, soft sensing, soft mechanics, and soft storage devices. A fifth theme, soft matter robotics, was also established by combining the outcomes from the other four themes, with the aim of further industrial innovation (Fig. 1).

Conventionally, mainstream robotics gave the impression of being hard and cold, but as we work towards a future in which humans and robots coexist as a matter of course, in recent years people have called for the development of safe robots that are nice to touch. "We thought that organic materials were exactly the thing to accomplish this. Accordingly, we created the concept of soft matter robotics--a departure from the normal robot field--and aimed to create robots using only organic materials in OPERA," says Special Professor Ohba. As Robotics is called comprehensive synthetic engineering, a wide variety of inter-disciplinary technologies are required for this field. By establishing easy-to-understand goals, the research team has skillfully integrated four types of independent fundamental research projects, enabling them to foresee the practical application of their outcomes.

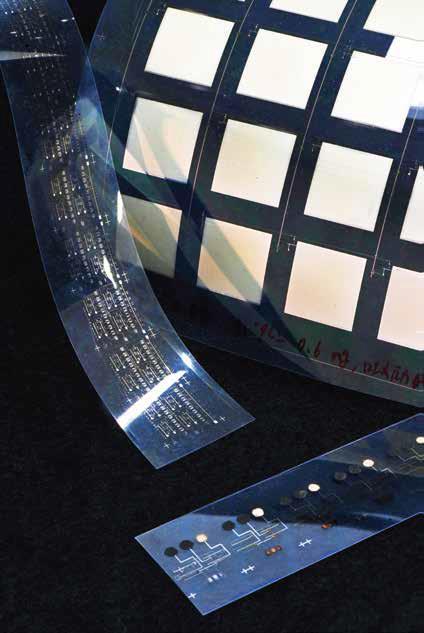

For example, in OPERA, the research team has focused on mass production technology for thin film devices that have been low-cost, flexible, and durable in the past. Low-cost, flexible, and durable thin film devices can be mass-produced by fabricating circuits using 3D printing technology on large-area plastics, and then finished by affixing sealing or barrier films that protect organic semiconductors from moisture and oxygen. "This doesn't just improve printing technology; its system, which integrates everything from optimal circuit design to product evaluation, is its strength" explains Special Professor Ohba.

In addition, the research team has developed small, lightweight lithium-ion batteries with enhanced safety by using a semisolid electrolyte. The development of small contact and temperature sensors with low power consumption and the perfect power adjustment to make sushi and pick up tofu was another success (Fig. 2). They have also achieved successive successful outcomes for pipe inspection robots, which move freely through the inside of narrow water or gas pipes and check for damaged areas (Fig. 3). The pipe inspection robots carry out their task while creating a map of the inside of the pipes, and even return by themselves to the pipe entrance. All the electronic components inside are airtight, so these robots do not break down even if they get wet, and their snake-like shape, made with small connecting units, allows each unit to freely change direction and rotation; this prevents them becoming entangled with dirt and floating substances in the pipes. All this technology was developed with the aim of being installed in robots, but research that looks to apply it on its own is also progressing.

"We decided in advance that the application of this project would be the creation of soft robots, and so the researchers set themselves goals one level higher than they had in the past. That inevitably raised the quality of our outcomes, " Special Professor Ohba says proudly.

Realizing the gap between research sites and society

Emergence of new issues through product development

In soft mechanics, the research team is focusing on developing soft actuator technology using 3D printing, which is a sustainable process that produces zero waste. Professor Hidemitsu Furukawa, a member of the Academic Assembly of Yamagata University, plays a central role in this area. He explains, "Unlike machines, living things can move their bodies flexibly and efficiently with very little energy, without generating heat or making noise. Our ultimate dream is to realize this by using soft organic materials known as gels." His team is trying to create artificial muscles using gels and 3D printers.

In OPERA, the team has succeeded in developing a robot to grab things without electricity--they have managed this by using 3D printers and sticking two types of gel together, then making use of the different rates of heat expansion between the inner part and the outer part. "If we can develop technology that freely sticks different materials together to improve functionality, that will lead to the development of soft actuators that run with low power consumption," says Professor Furukawa.

Professor Furukawa went on to talk about the untold story of the development of the "gel jellyfish" robots, which were made using gel and 3D printers (Fig. 4). "We created gel jellyfish that give off a highly efficient glow by packing sensors that we had developed together with light-emitting devices. After these were completed, we planned to accompany the Japan Agency for Marine-Earth Science and Technology on an ocean survey and have them detect ocean temperatures and pollutants in the water," he says, explaining the initial research plan. Since the research was progressing favorably, they decided to show the gel jellyfish to a jellyfish specialist and took a prototype to Kamo Aquarium (Tsuruoka City, Yamagata Prefecture), which is famous for its jellyfish. Although the head of the aquarium evaluated it as being the spitting image of a real jellyfish, the team was asked to make something that was closer to an actual jellyfish, rather than adding features such as making it glow and measure things. That being the case, the team worked to devise ways to replicate a jellyfish's floating movements, using moon jellyfish as their model, and ways to add tentacles.

They also had support from a company that anticipated that the jellyfish would be visually soothing and talks to commercialize them went ahead. However, when the company representative saw the prototype, they rejected the tentacles, which they thought were "eerie," and in the end only the jellyfish bell was commercialized. "We know about the 'uncanny valley' phenomenon, in which people see androids made to look exactly like humans and feel uncomfortable, but I was surprised that the uncanny valley effect could be caused by other living creatures," Professor Furukawa says with a wry laugh.

There were more inquiries than expected about the gel jellyfish that were released for sale--25 units have been sold so far, mainly to hospitals, care facilities, and for bank waiting rooms, and all have received positive reviews. Thinking about this example, both Special Professor Ohba and Professor Furukawa agree that "Researchers and engineers have a tendency to slavishly seek to create something that performs well and is exactly like the real thing. That is not a bad thing for research. Nevertheless, we learn that when thinking about practical applications, societies do not necessarily want the performance and ideals that researchers aim for. When developing this product, many different people offered us their opinions, and we were able to improve it--this was a good experience."

Creating value with softness and exploring new needs in exhibitions

Special Professor Ohba and his research team have brought industry, academia, and government together, focusing on four fundamental technologies that will help to realize soft matter robotics. The culmination of their efforts has led to the development of Gel HACHI (Title Image). This robot was modeled on the Tsuruoka Hachiko statue, a plaster statue in safekeeping that was created as a prototype for the Shibuya Hachiko statue.

The head and front paws are made from a soft gel material using 3D printers and were designed to make people instinctively want to touch them. There are tactile sensors embedded in the robot, so it can detect when people are touching it and stroking it. It also has systems that employ artificial intelligence to analyze the emotions of the people who talk to it based on their voices. Gel HACHI's collar glows blue if someone's voice sounds lonely, and red if it sounds upbeat, and the noises it makes also change. Professor Furukawa looks back at when it was exhibited in Shibuya Hikarie in the Super Welfare Exhibition held in 2019: "The visitors were surprised to learn that they could communicate with Gel HACHI, and, at the same time, they would start trying to deepen their interactions with it. Because it has an emotional analysis system, Gel HACHI likely made people feel as if it was cuddling close to them."

In 2020, an improved version of Gel HACHI was once again exhibited at the Super Welfare Exhibition. As this was held in the middle of increasingly strong measures against the spread of COVID-19, the research team explored merits other than being nice to touch. Professor Furukawa clarifies his team's aim: "We attached an infrared sensor to the collar and added a function that would casually measure visitors' temperatures. We knew from the previous exhibition that people would naturally gather around Gel HACHI, which would lead to interactions, and so we made use of that." The response from the exhibition was that if Gel HACHI was placed at the entrance to elementary schools or facilities, people would probably cooperate and have their temperature taken without feeling uncomfortable. "Since it feels nice to touch, a lot of visitors wanted to touch Gel HACHI. Just making a thing soft gave it enormous value," notes Special Professor Ohba. Hearing the evaluations of users in the exhibition space, the team really felt the power of soft materials and the possibilities of organic materials.

In November 2020, the team presented another improved version of Gel HACHI called Gel Hachiroid, which has an even more enhanced soothing effect. Its body feels soft and warm to the touch, and its eyes, made from a newly developed gel material, can shed tears. It was designed to feel more affectionate and like a living creature, bringing it one step closer to being used in care facilities and homes. The team will continue their research, aiming to create a robot that people will want to live with, based on user opinions.

Cultivating personnel across the region: working towards a global research hub

Plans to accelerate the commercialization of these outcomes are in motion. The OPERA project entered its final phase in FY2020, but Yamagata University says it will maintain the system that unites a wide range of personnel, including students, young company researchers, and engineers, and allows them to flexibly participate in research projects. Special Professor Ohba and Professor Furukawa both agree that "We will enhance the system even more, working towards the cultivation of research personnel and world-leading research. Through the product development we have carried out to date, we have learned that there are a lot of people with many different skills around the University."

If the research team can involve people who have not yet had contact with the University, they will be able to achieve research and development from a wider range of perspectives as they work towards commercialization. They are still in the process of creating a structure for this but will go ahead with a project that involves the participation of local people, aiming for Open Innovation 2.0, which will solve issues through multilayered collaboration between industry, academia, and government. Special Professor Ohba and Professor Furukawa continue to move forward so they can make the whole region centered on Yamagata University a global platform for organic material systems.