The sulfated polysaccharide sacran, which was discovered in Suizenji nori (a type of Japanese seaweed) by university researchers 14 years ago, is a supramacromolecule with a molecular weight of more than 10 million daltons. Soon after, the molecule was used as a moisturizing and film-forming agent in a variety of domestic and foreign products, including the Sacre™ product line.

Background and overview of Suizenji Nori and Sacran

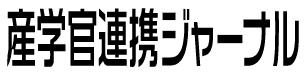

Sacran, a novel sulfated polysaccharide discovered by the authors in 2007, is currently used in several products as a moisturizer and is as a substance with the characteristic of producing a certain commodity value. Sacran is isolated from Suizenji nori (scientific name: Aphanothece sacrum), which is a cyanobacterium (blue-green alga) that is indigenous to Japan (Fig. 1, left). Suizenji nori is cultivated in northern Kyushu using groundwater/spring water and is used in food. Among more than 2000 known algal species, only Suizenji nori can be eaten, cultivated, and used in the mass production of sacran. The authors' research group, which is investigating the use of biomass feedstock for plastic production, is considering cyanobacteria as a raw material for producing biomass plastic, which is an essential commodity to sustainable societies.

While screening cyanobacteria for useful substances, we noticed that the wash water layer from the liquid-liquid extraction process contained a large amount of "gelatinous substances". After precipitation with alcohol, the gelatinous substances were recovered as hard and fibrous cellulose-like materials (Fig. 1, right). We speculated that these substances were polysaccharides and analyzed their structures. The polymer was composed of a novel constituent sugar, a sulfated muramic acid, which was named "sacran".

Since Suizenji nori can yield as much as 50¬-70% sacran per unit of dry weight, we hypothesized that sacran could be a useful indigenous source of biomass in Japan. However, there were risks associated with using this new substance, and it was difficult for most companies to include it in their products. Therefore, we launched a venture company that received support from the National Research and Development, Japan Science and Technology Agency (JST)--once in 2008, as part of the Industry-Academia Joint Seeds Innovation Business Realization Stage, and again in 2018, as A-STEP (Adaptable and Seamless Technology transfer Program) Functional Verification Phase. The funds were used over a period of 10 years to advance the structural analysis, functionalization, and practical application of the substance. Sacran is currently used as a moisturizer in various countries in Central and South America, Europe, and Asia. The details are described below.

Sacran structure and function

Elemental analysis, spectroscopy, and chromatography revealed the following about the structure of sacran:

- Sulfate content of approximately 12 mol% per sugar residue

- Carboxylic acid content of approximately 27 mol% per sugar residue

- Eight or more constituent sugars, including neutral sugars, amino sugars, and uronic acid

- Weight-average molecular weight of at least 107 g/mol (polyangular static light scattering method: absolute method)

In other words, sacran molecules are supramacromolecules that are composed of up to 100,000 sugars linked together and that possess negative charge contents of 39 mol%, which is equivalent to up to 30,000 negative charges in each molecular chain. The most characteristic function of sacran is its high water-retention capacity. Although it is common to use coarse materials such as kitchen paper to evaluate water retention, in an effort to quantify the water-retention capacity of a substance before it undergoes chemical cross-linking, we established an improved tea-pack method. This measured the amount of unbound water that passed through an 8-μm fine filter paper upon which an aqueous sacran solution was placed. According to this method, hyaluronic acid could hold 1200 times its own weight in water. However, sacran was capable of holding approximately five times this amount, or 6100 times its own weight. When saline was used, the water-holding capacities of hyaluronic acid and sacran were reduced by 10- and 2400-fold, respectively. In addition, the amount of artificial urine retained by sacran was 2600 times its weight, which is approximately 50 times higher than the retention capacity of macromolecular absorbers used in diapers. Since sacran attracts both water and polyanions, the gel is formed via strong interactions with cationic polymers, such as collagen and metal ions.

Sacran molecules also have the ability to form helical configurations and water-dispersing, multi-walled carbon nanotubes. The high molecular weight of sacran is responsible for its extremely high solution viscosity. However, sacran also exhibits reversible pseudoplastic properties: it becomes smooth and free flowing when a shearing force is applied and returns to a viscous state when left standing. When drying sacran in a narrow space, it was also found that its high viscosity results in a unique self-organizing tendency; it forms oriented films that bridge the walls that separate these narrow spaces. In addition, sacran exerts anti-inflammatory effects.

Along with Associate Professor Ngatu Roger (formerly Kochi University School of Nursing, currently Kagawa University School of Medicine), we tested the water-holding and film-forming abilities of sacran in humans and found that sacran markedly reduces transepidermal water loss (TEWL) and exhibits remarkable moisturizing and antipruritic properties (Inhibition of itching sensation). Sacran application can protect the stratum corneum and reduce skin dryness and itching, which aggravate atopic dermatitis.

Sacran as a new material

In Suizenji nori, sacran is secreted as an extracellular matrix that protects cell bodies. In other words, sacran exists as a gel in Suizenji nori and functions as a scaffold for cell division. If this property is the basis of the fundamental role of sacran, the best use of the substance would likely be related to cell culture scaffolding and wound dressing. Hydrogels can be formed by chemically cross-linking sacran molecules. However, the use of highly irritating cross-linkers is undesirable for biomaterial applications.

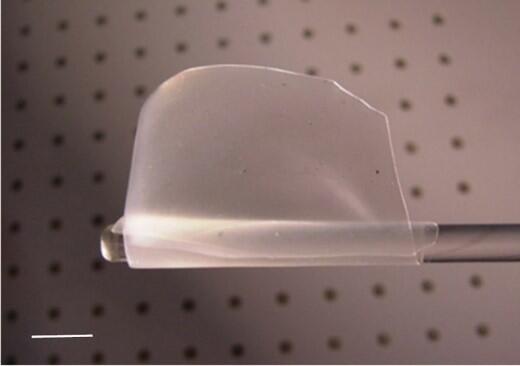

Therefore, we developed a method by which sacran is formed into cast films, cross-linked by heat treatment, and then gelled. When film-like sacran gel sheets are heat-treated at 70-140 °C, different degrees of swelling (with fluid) are observed at different temperatures (Fig. 2). Moreover, the gel sheets exhibit anisotropy, mainly swelling longitudinally and very little laterally. Such gel sheets could be utilized as protective agents for wound sites and as cosmetic pack agents. Research into the cell culture scaffolding function of sacran revealed that L929 murine fibroblast cells were able to extend along the liquid crystal orientation of sacran. Our laboratory is now mixing sacran with other polysaccharides to develop transparent, flexible, and strong complex films. The development of the application of this film as a polymer absorber and wound dressing is planned in the future.

Mixture of sacran and rayon fibers

Together with commercial corporations, we have also developed a new ingredient, Sacre™, which incorporates sacran into rayon fibers. We believe that sacran is able to mix with rayon because it has the following features:

- Major structural features of a glucan (similar to cellulose)

- Alkaline tolerance of pH 14

- Heat resistance of about 110 °C

- Resistance to acid degradation

Sacre™ is prepared as follows.

Cellulose is subjected to sodium hydroxide treatment, left to stand, mixed with carbon disulfide, which results in the production of sodium cellulose succinate and the loss of intramolecular hydrogen bonds, and dissolved to form a colloidal solution.

This colloidal solution and an alkaline aqueous sacran solution are mixed, and the resulting cellulose-sacran solution is spouted from fine holes into dilute sulfuric acid and wet-spun.

The sodium cellulose succinate then converts back to cellulose and regenerates as fibers via intramolecular hydrogen bonding.

We believe that sacran is blended into rayon during this process.

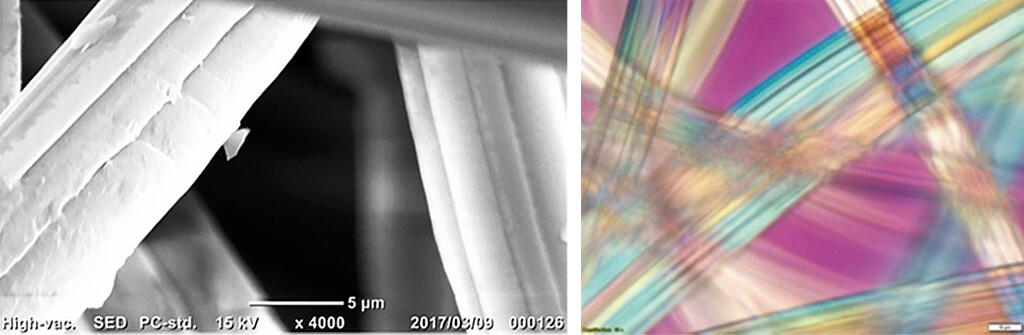

Scanning electron microscopy revealed that the introduction of sacran affects the surface structure of rayon fibers by generating nano-scale irregularities (Fig. 3 left). This confirms that sacran is present on the surface of the rayon fibers, which are otherwise smooth. Measurement of the water absorption capacity of Sacre™ revealed that the addition of sacran improved the amount of water absorbed by rayon fibers by approximately 28% (Fig. 3 right). Indeed, Sacre™ exhibited hydrating/moisturizing properties that far exceeded the conventional rate of rayon fiber hydration. In addition, the unique soft texture of the rayon fiber is not impaired because the sacran is kneaded into the rayon fiber and the notable water-holding capacity of sacran improves the product's soft texture without affecting washability. Therefore, when Royne Co., Ltd. (Shinagawa, Tokyo), a clothing manufacturer and distributor, knitted a fabric blend that contained 30% Sacre™ and cotton-blended bare tenjiku, the fabric's moisture absorption and desorption properties were increased by 20%. Therefore, we began to produce underwear using Sacre™ and created products that target individuals with easily irritated skin, such as the elderly, infants, and individuals with sensitive skin. These products have been sold on the market for over a continuous period of 2 years.

Summary and Perspectives

Sacran is a unique material with a variety of characteristic structures and functions that, as a novel polysaccharide, can be developed into high-value-added materials. Since sacran is derived from a species that is native to Japan, it can also be considered a Japan-derived type of biomass. Sacran has already been used as a raw material for many cosmetics, as a moisturizer, and as a coating agent, and the range of practical applications has been increasing on a yearly basis. We also look forward to using sacran in polymer composites, such as Sacre™.

We envision that sacran can be used in a variety of material forms, including films and gels, and we are particularly interested in developing such materials for medical applications. Therefore, it is crucial to reduce the cost of Suizenji nori as a raw material. By focusing our efforts on the practical application of these organisms as plant factories, we have achieved significant milestones and believe that our target can be achieved in the near future. Finally, we expect that these efforts will facilitate the conservation of Suizenji nori, which is an endangered species.

Tatsuo Kaneko

Professor, Environment and Energy Area, Graduate School of Advanced Science and Technology, Japan Advanced Institute of Science and Technology

Maiko Okajima

Industry-academia collaborative researcher, Cyanobacterial Engineering, Graduate School of Advanced Science and Technology, Japan Advanced Institute of Science and Technology