In recent years, while the development of technology has made comfortable living possible, it has also had an adverse impact on the environment and we are under pressure to shift to a more sustainable society. The "ERATO Kawahara Universal Information Network Project," led by Professor Yoshihiro Kawahara of the University of Tokyo's Graduate School of Engineering, is attempting to build basic technologies and realize the ideas required for next-generation devices. Dr. Kawahara and his team are attempting to create novel possibilities for coexistence using environmentally friendly 'Goldilocks' tools that are just right in terms of design and performance for users.

Overcoming enslavement to technology

Considering social implementation with 3 themes

With the development of technology, human values and industrial structures have been altered. In the modern era, where sensor networks and IoT devices have become popular, daily life is significantly more convenient and comfortable than before. However, it is not uncommon to be influenced or overwhelmed by complicated functions and excessive information that cannot be mastered. A smartphone, which holds all of a person's information, causes not only physical distress but also psychological anxiety if it is misplaced. Due to these factors, it can be said that people are being dominated by tools.

Professor Yoshihiro Kawahara of the University of Tokyo Graduate School of Engineering established the "ERATO Kawahara Universal Information Network Project" to redefine a better relationship between people and technology and to invent next-generation technologies. "In this project, we have aimed to bring new value to society and make our lives better by creating eco-friendly technology that is convenient for everyone to utilize," he said. Technology has evolved in such a way that an invention is quickly adopted in several fields, instantly altering the technological landscape. He says that if the restrictions pertaining to current tools, such as location, and knowledge can be overcome, new possibilities will naturally be created. Meanwhile, Takram's director Hisato Ogata, who participates in the project as a design engineer, cites the words of Ivan Ilyich, a philosopher who was active in the 1970s, as a guide to analyzing the challenges of modern technology. Ilyich, who was also a critic of civilization, revealed that there are two states, one in which tools maximize human ability and creativity, and another in which the evolution of technology deprives humans of their independence and enslaves them. The transition between these two is described as a "watershed." "Though these are the words of a man that lived more than half a century ago, they accurately indicate the challenges of modern technology. For ERATO, too, it is important to analyze the right level of tool: neither insufficient nor excessive, but one that is just right."

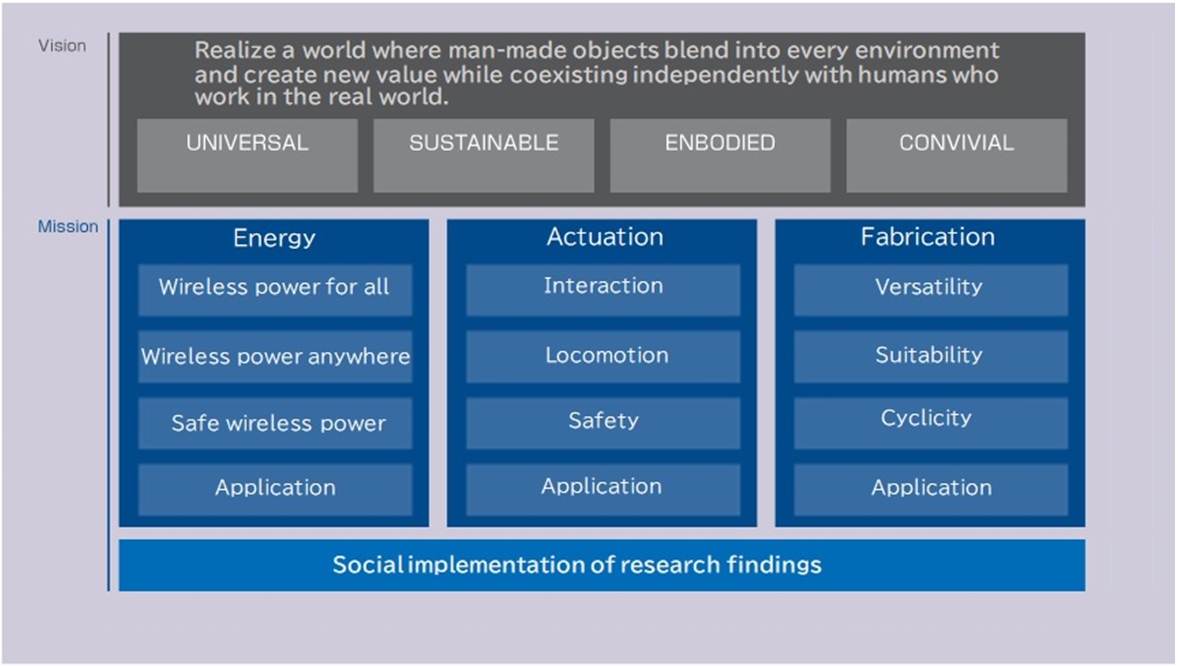

In this project, the elements of tools required in the future are summarized into four points: "universal," "sustainable," "embodiment," and "conviviality." Researchers are actively conducting challenging, creative, and integrated research beyond the extension of existing IoT research (Figure 1). Specifically, researchers are focusing on three themes:"energy" for operating sensors and computers, "actuation" for the mechanism that moves them, and "fabrication" for easily creating sensors, computers, and the prototypes incorporating them. While advancing technologically, they are also studying social implementation methods that cut across that process.

Wireless charging anywhere

Moving to a world where batteries never die

When sensors and computers are utilized, one must first decide how they are to be powered, thereby limiting where they can be used. Large equipment has no needs for mobile use, but in the current age, one can work anywhere with a PC. If electricity can be supplied anywhere, various devices can be utilized without location restrictions.

"One of the answers to this challenge is wireless power supply. We have built a system that allows devices to be charged without an outlet or charging cord," explains Kawahara. By embedding a power transmission mechanism in the walls and floor, a space in which power in the order of several tens of watts can be wirelessly transmitted anywhere in a 3 m2 room has been realized (Figure 2 ). " Regarding wireless charging, some individuals are worried about the effects of electromagnetic waves being dispersed throughout a room. However, this technology solely utilizes the electric and magnetic fields that form electromagnetic waves, which have a relatively lower degree of interference with the human body. We have realized a safe design in accordance with international guidelines and realized a wide range of highly efficient power transmission." If there are no outlets in the room, and no cords for the equipment, then the degree of freedom in its layout will increase.

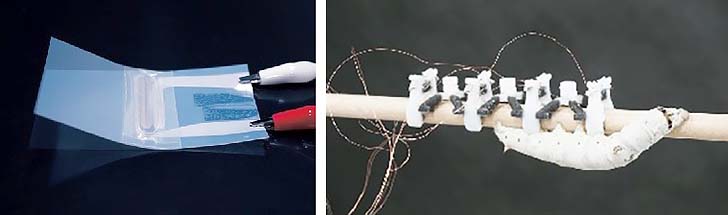

A sheet that enables wireless charging, even when you are away from home, has also been developed. The sheet incorporates coils utilized for the transmission of radio power and can be utilized freely by the user to match the shape of equipment, bags, clothing, etc. (Figure 2). With this sheet, it is possible to transform everything around an individual into a wirelessly chargeable product. In a world where a universal information network is realized, the concept of a "dead battery" no longer exists.

Developing soft robots

Trial and error with prototypes

In a universal information network society it is assumed that sensors move, and robots positively work for the environment. Because they are utilized in human living spaces, it is necessary to devise ways to prevent injury, even if they come into contact with humans. "Soft robots using soft materials are a current trend in robot development. We are not just studying materials but also soft movements," says Ogata. The researchers are also working on the development of materials that can be freely deformed even with a slight exertion of force, and devices that generate mechanical forces using electricity, magnetic force, and air pressure.

One of these is the "pumpless actuator" (Figure 3). When electricity flows through a circuit printed on a sheet that is less than 1 mm thick, the sheet contracts slowly, producing approximately as much force as is required to bend your little finger. We have also developed a hornworm-type soft robot, modeled on a hornworm that can move around freely, even in places where humans cannot go, such as on thin branches at high altitudes or on electric wires (Figure 3). Modest movements that could not be reproduced by conventional robots with heavy and hard materials have become possible. "It may seem like a toy at first glance, but novel ideas and technologies are needed to reproduce this movement. Based on these products, novel ideas will be developed and increasingly used," says Ogata.

The fabrication techniques required for making these products independently have also been developed simultaneously. Conventionally, specialized and dedicated equipment have been required for manufacturing, but by utilizing digital data, it has become possible to manufacture in large quantities at low cost. The project attempts to refine this fabrication to an intuitive level without the need for expertise in the field using eco-friendly materials. "It is very important to try making things first and then repeatedly iterate through trial and error," he emphasizes.

An example of this is the 3D printer, "Dynablock" which can freely output three-dimensional shapes within a timeframe of seconds to tens of seconds (Figure. 4). Stacked 9 mm size blocks are extruded from the bottom only where necessary, to create a three-dimensional shape." These blocks contain magnets that can be manually recombined and granularly modified, even after they have been modeled. If the blocks are small, they will also be applicable to authentic product design," he said. In addition, "Proto Mold," which aspirates a thermoplastic resin that can be utilized repeatedly, and fixes and cures it in a mold, is expected to be applied to packaging materials (Figure 4). There is no doubt that the landscape of next-generation 3D manufacturing will change significantly in the future.

Next-generation vehicle "poimo"

Lightweight and portable

The personal mobility vehicle "poimo" is the result of embodying the three themes of "energy", "actuation", and "fabrication" (Figure 5). It is a next-generation vehicle that connects small distances from public transport to the individual's destination. The body is inflatable and can be folded and carried in a bag when deflated. It is also possible to create a vehicle that fits the user size, by simply having them assume a riding pose on the device. There are high expectations from entities in this industry that this device will enable everyone to choose a safe means of transportation that suits them.

"Because the body is soft, it will not cause a severe accident if it hits someone. The sofa type was popular with the test riders. Due to the current COVID-19 pandemic, we received several inquiries from overseas," says Ogata, talking about the magnitude of the response to their invention. As there are still challenges to be considered for practical application, Dr. Kawahara concludes that it is not a finished product and that it was presented with "room for improvement." This is because opinions from outsiders may inspire new research themes and joint research. Dr. Kawahara's own experience of identifying the base properties, while flexibly alternating between the field and theory is applicable. Dr. Kawahara points out that people's reactions are quite different when a thing is abstractly explained, as opposed to when they are faced with it in reality.

Those who actually experienced the test drive and other events proposed several of their own conceptions of the future of poimo. "Currently, the possibility of autonomous driving and rental services is being considered," he said. Currently, research is underway for practical use, in collaboration with Mercari (Minato-ku, Tokyo), an operator of flea market apps.

Challenge with a mixed team

Joint research where 1 + 1 = 3

Individuals from a wide range of fields such as mechanical engineering, information and communication, LSI technology, and design are involved in the project, which continues to expand in various fields, and more than 100 students have participated. The researchers are also actively working with individuals from foreign countries. More than 10 researchers have been dispatched to or accepted from overseas. "A mixed team of engineers, scientists, artists, and designers is taking on the challenge of developing a variety of basic technologies centered on the three themes of energy, actuation, and fabrication," said Kawahara.

Research themes are different, but the objectives of the project have been checked and aligned from time to time. When project members complete a product or concept, they create a postcard or video to present their ideas. Photographs and videos are taken by the researchers themselves and accompanied by a message to accurately convey the technical content and core ideas to viewers. "Before the pandemic, we had regular weekly meetings and yearly training camps, " says Ogata. "There are certain observations that can only be made by getting together in the same place, having each team present their ideas, and discussing amongst one another. "Currently, Web conferencing tools are being utilized, and mentors are now able to respond more individually and carefully in these large group sessions. "Although research themes may overlap, we are also discussing how to develop joint research projects that will make 1 + 1 = 3, so to speak. If two teams can publish three papers, there will be mutual benefits," he says.

The activities of the project will be completed at the end of 2021, but some of its research will continue at the University of Tokyo Research Institute for an Inclusive Society through Engineering (RIISE), which was established in 2020. The researchers aim to leverage the seed companies born at the university into corporate collaborations. Drs. Kawahara and Ogata aim to build a better relationship between people and technology and will continue to create "Goldilocks tools" for the next generation.