Ahead of the 2025 Japan World Exposition (Expo 2025 Osaka, Kansai, Japan), all eyes are on Science and Technology Innovation developments (STI for SDGs) to achieve the Sustainable Development Goals (SDGs). Kansai is a region of commerce, and many companies and organizations aim to contribute to the SDGs worldwide by using their unique technologies. We introduce Smileyearth (Izumisano City, Osaka), which has reduced the environmental burden of towel production, and the Research Center for BNCT of Osaka Prefecture University (Sakai City), which leads industry-academia-government collaboration towards the spread of new cancer treatment methods.

The Challenge of the Towel Company Began in Japan's Dirtiest River

"Monozukuri Nippon Grand Award," sponsored by METI, the Ministry of Economy, Trade and Industry, shines a light on people who take on the challenge of manufacturing in the new era. Smileyearth, which won the 7th METI Minister's Prize in 2018, has only five employees but has had a strong presence with its enthusiastic efforts toward the SDGs, including winning the Excellence Award at the JST-sponsored "STI for SDGs" Awards in 2019.

The Senshu area of Osaka is the birthplace of Japan's towel production and boasts a history and tradition of about 130 years. Tatsumasa Oku, the president of Smileyearth, was born and raised in this area as the third generation of a towel manufacturer. In 1998, the Kashii River, which runs through the area, was ranked lowest in a nationwide survey of river water quality conducted by the Ministry of Environment. Oku, who was in the fifth grade at the time, felt pained to learn that his family's towel business was one of the reasons for this.

Generally, a large amount of water is used in towel production. Towels are highly absorbent, but their raw material, cotton, contains oil and repels water. This resulted in massive spills of treated water from the chemical agents and dyes used to remove oil and impurities.

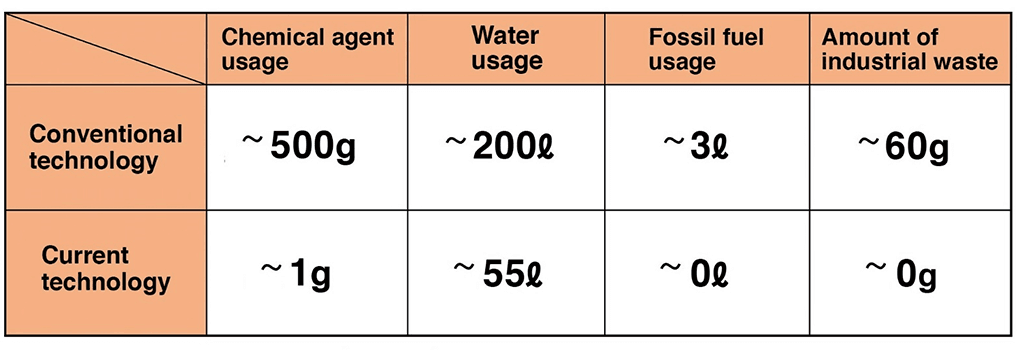

"It is said that 500 grams of chemicals are needed to make one kilogram of towels. At times, annual production was tens of thousands of tons, and half that amount of chemicals were also used."

Japan's towel industry peaked around 2000 but has been shrinking ever since. Dominated by inexpensive imported products, the number of towel-related companies in Senshu, which used to be over 700, has now fallen to less than 100. However, Ryuichi Oku, the father of Mr. Oku, turned this challenge into an opportunity.

Unique technology that focuses on cotton's natural purification

Towel manufacturing is generally divided into companies that make yarn from cotton, weave companies, and dye companies. While many of his competitors went out of business, Ryuichi bought their machinery and equipment and established an integrated production system at his company. He also approached Yuichi Kashiwada, who was undertaking organic cotton cultivation in Uganda at the time. Tatsumasa, the current president, also went to Uganda after graduating from university, and this was when the challenge of creating a genuinely organic towel began.

In general, even organically grown cotton is treated with chemicals when being made into towels. Oku questioned whether such towel production was "truly organic" and started to investigate on his own. He discovered that cotton has a self-purification function and then developed the "self-cleaning cotton method" that maximizes this function. He achieved the same effect as the conventional chemical-based scouring process using only cotton and water, reducing the amount of water used to about one-fourth and the chemical agents to one-fifth.

(Prepared based on the image provided by Smileyeath)

Smileyearth is pursuing sustainability of towel production and the global environment with STI for SDGs. As an "SDGs manufacturer," the company has set nine goals to tackle ― "Responsible consumption and production" "Life below the water," and others ― out of the 17 SDGs goals.

Ultimately, Oku hopes to build a recycling system that reuses treated water as a water resource for cultivating crops and other purposes to realize a "Nature Towel Factory," a towel factory for a new era. Now, people connected through "water," like local farmers and fishermen, push him forward.

Boron sheds new light on cancer treatment

The SDGs also include the goal of "Good health and well-being for all." There is growing hope for STI for SDGs in the medical field as well. The Research Center for BNCT at Osaka Prefecture University is playing a central role in industry-academia-government collaboration to promote the spread of a new cancer treatment method called Boron Neutron Capture Therapy (BNCT). The BNCT drug the center developed obtained pharmaceutical approval for the first time globally and then got covered by insurance in 2020.

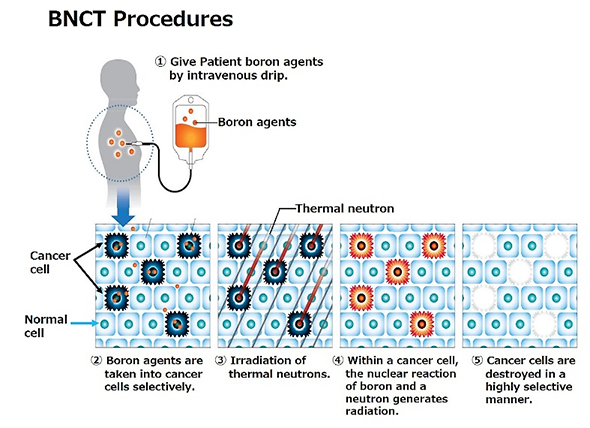

BNCT is a type of radiation therapy. The boron drug is administered intravenously so that boron can be taken up by the cancer cells in advance, and then be irradiated with a low-energy thermal neutron beam to destroy the cancer cells. Since it does not damage normal cells, it is expected to be a treatment method with a lower physical burden.

BNCT's principle was put forward in the United States in 1936, and its research had been going on for a long time. However, Mitsunori Kirihata, Director of the Research Center for BNCT, Osaka Prefecture University and Project Professor of the university's Organization for Research Promotion, says, "Solving the two bottlenecks was essential to succeed in the clinical application of BNCT."

The first issue was boron. There are two boron isotopes, boron-10 (10B) and boron-11 (11B), that exist in nature at a ratio of 1:4. However, only boron-10 splits in response to thermal neutron radiation. In other words, technology to enrich boron-10, which only occurs at a rate of 20% naturally, was required.

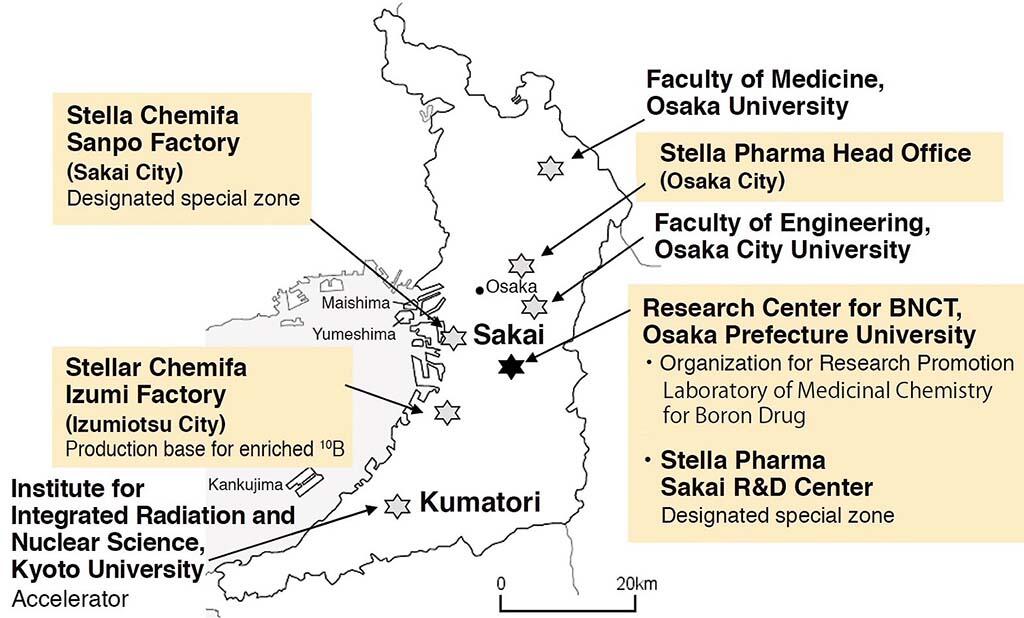

Stella Chemifa, a chemical manufacturer headquartered in Osaka City, made this possible in Japan. In 1999, Kirihata met Tomoyuki Asano, an employee of the company, which led to the full-scale development of boron compounds for BNCT. Today, Stella Pharma, a subsidiary of Stella Chemifa and chaired by Asano, is the only company in Japan engaged in developing drugs exclusively for BNCT.

Blessed with "harmony of people" more than anything else

In addition to this, BNCT research institutes are concentrated in the Kansai region in various fields such as medicine, pharmacology, and physics, including the Institute for Integrated Radiation and Nuclear Science, Kyoto University, which has led the world's BNCT research. This rare environment greatly supported development of BNCT.

(Prepared based on the image provided by the Research Center for BNCT, Osaka Prefecture University)

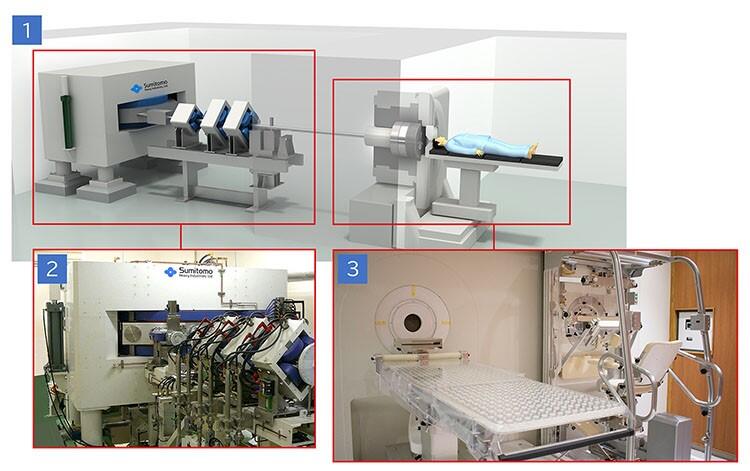

The second issue was the neutron irradiation equipment. Transporting patients from the hospital to the research reactor was not practical. Sumitomo Heavy Industries, Ltd. solved this problem by developing a compact neutron generator to be installed in hospitals.

2. Cyclotron: extracts proton beams and converts them into neutrons.

3. Treatment section of the BNCT irradiation room.

(1, 2: Provided by Sumitomo Heavy Industries, 3: Provided by Kansai BNCT Medical Center, Osaka Medical and Pharmaceutical University)

Looking back on the development to date, Kirihata says that he has been blessed with "heavenly timing, a local advantage and harmony of people." As for the local advantage mentioned earlier, BNCT's element technologies gathered in the Kansai region was a significant factor. In regard to the opportunities 'heavenly timing,' the trend of promoting industry-academia-government collaboration was important. Stella Pharma's commercialization development was supported by JST from FY2008 to FY2014 and the Japan Agency for Medical Research and Development (AMED) from FY2015 to FY2019. The base of this industry-academia-government collaboration was the Research Center for BNCT, which started in 2014 on the Nakamozu Campus of Osaka Prefecture University.

Kirihata says that he was blessed with the "harmony of people" more than anything. "Mr. Asano, who established Stella Pharma to deliver this technology to patients, and the doctors who cooperated in the clinical trials―the thoughts of the people involved was a major driving force."

Kirihata also expresses his enthusiasm to focus on nurturing specialized human resources in the future. "First of all, we need to continue fundamental research to expand the range of cancer applications. On the other hand, it is also essential to look at medicine from the larger perspective of the global environment surrounding us, rather than just chasing technology. What thought system can we build for sustainable development, and how can we use our expertise? It overlaps with the idea of the Expo, and I would like to value human resource development as well."

Kansai companies that stand out on a global scale

Many other companies in Kansai have developed their unique ways of doing business while carrying on their traditional industries. METI selects "100 Global Niche Top Companies" that have established a leading position in the world market in a specific product or service field. The list has been put together twice in the past, in 2013 and 2020, and 113 companies were selected in 2020, of which Kansai companies did remarkably well, with 21 selected from Kyoto, Osaka, and Hyogo prefectures.

On the other hand, in the World Economic Forum's "Global 100 Most Sustainable Corporations in the World (Global 100 Index)," which annually ranks the world's 100 most sustainable companies, five Japanese companies ranked in 2021. Companies from Kansai also made their presence felt here. Takeda Pharmaceutical Company Limited, selected for the sixth consecutive year, was founded in Osaka City, and Sekisui Chemical Co., Ltd., ranked four years in a row, is also headquartered in Osaka City.

Kansai has the power to lead the world in achieving the SDGs. The actions of every one of us are also essential to realize the theme of Expo 2025 Osaka, Kansai, "Designing Future Society for Our Lives." Now is the time for us to think about the future of science, technology and humanity ― what kind of planet will we pass on to the next generation?

OKU Tatsumasa

President of Smileyearth Corporation. He was appointed as the official coordinator of friendly exchange between Japan and the Republic of Uganda in 2017, received the METI Minister's Prize at the 7th Monozukuri Nippon Grand Awards in 2018, and was presented the first Ambassador's Commendation at the Embassy of Japan in Uganda in 2019.

KIRIHATA Mitsunori

The Director of the Research Center for BNCT, Osaka Prefecture University, and project professor of Organization for Research Promotion at the same university. Ph.D. (Agriculture). Having retired after working as a professor at the Graduate School of Agriculture and Biological Sciences / Life and Environmental Sciences, Osaka Prefecture University, he assumed his current position as a project professor of Research Center for the 21st Century and Organization for Research Promotion at the same university.

(HORIKAWA Akina, Fellow at Knowledge Mobility based System Institute (KMS) and Science Communicator)

Original article was provided by the Science Portal and has been translated by Science Japan.