If populations continue to grow, especially in developing and emerging countries, there is concern that the supply of meat protein from livestock alone will reach its limit. Professor Shoji Takeuchi of the Institute of Industrial Science, Graduate School of Information Science and Technology, the University of Tokyo, is trying to solve this "protein crisis." Research is ongoing to create steak-sized meat that is artificially produced using cutting-edge life science and engineering techniques.

This is at the forefront of "cultured meat" research, which is expected to not only contribute to solving the sustainable development goals (SDGs), such as food problems, but also uncover new food possibilities.

An urgent need to increase food production due to population growth: from food tech to new markets

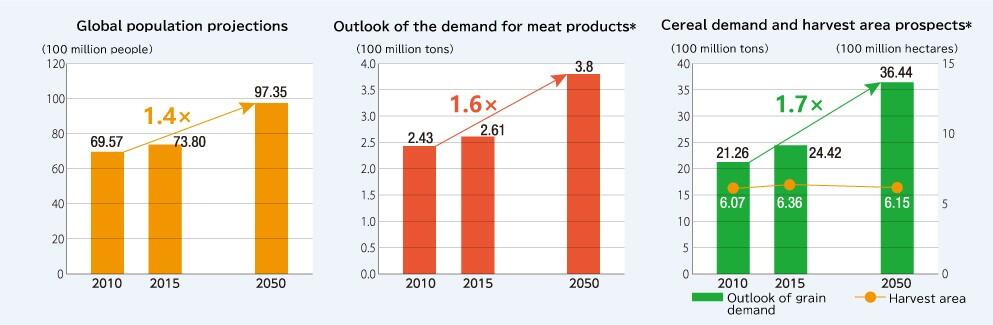

Of the 7.7 billion people in the world, over 800 million experienced famine in 2020. It is estimated that the population in 2050 will be around 9.7 billion; hence, increasing food production is an urgent global issue. However, forests need to be cleared to increase the amount of agricultural land, which goes against global warming countermeasures. On top of this, if livestock is increased, the increased feed requirements will divert further grain and water from human consumption (Fig. 1). As a solution to these problems, "Food Tech," which combines food and technology, is attracting attention.

In other words, if the yield per unit area cannot be greatly improved, both edible cereals and forage cereals will be scarce, leading to a food crisis.

* 1. Here, grain refers to the sum of wheat, rice, corn, barley, and sorghum. 2. The 2010 value is a three-year average from 2009 to 2011, which is used to avoid the influence of data fluctuations due to annual weather changes. 3. The 2015 value is a reference value calculated based on the actual value of the three-year average of the production, supply, and distribution (PSD) of the United States Department of Agriculture (USDA) from 2014 to 2016.

(Sources: Statistics Bureau, Ministry of Internal Affairs and Communications: "World Statistics 2021," and Ministry of Agriculture, Forestry, and Fisheries: "Global Food Supply and Demand Outlook for 2050-Forecast Results by Global Ultra-Long-Term Food Supply and Demand Forecast System-" (2019), formatted and modified by JST)

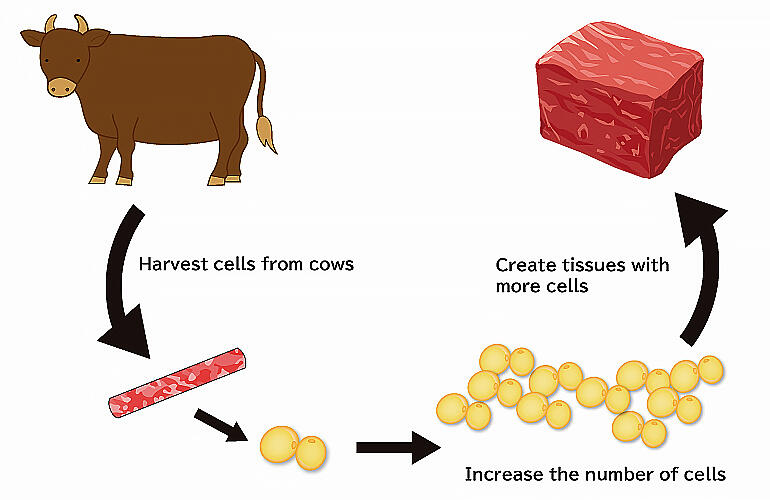

Among them, "meat substitutes" are emerging as a new foodstuff to replace meat. Meat substitutes made from plant-derived ingredients, such as soybeans, are already on the market, but the development of "cultured meat" that reproduces the flavor and texture of meat using cell culture technology is accelerating. Professor Mark Post of Maastricht University, the Netherlands, was the first to showcase the technology for producing cultured meat. Using cell culture technology and tissue engineering, which had originally been expected to be applied to medical treatment, researchers have succeeded in producing meat by extracting animal-derived cells from cattle and culturing them (Fig. 2).

A tasting party for cultured meat hamburgers was held in London, England, in 2013, and received a great response worldwide. However, the price of one hamburger was initially as high as 35 million yen, including research expenses; meaning that the appearance of cultured meat on the dinner table appeared to be wishful thinking. Since then, research and development have been progressing worldwide, which will assist in mitigating global problems, taking the advantages of avoiding animal slaughter and the low environmental impact of production into consideration.

Professor Shoji Takeuchi of the Institute of Industrial Science, Graduate School of Information Science and Technology, the University of Tokyo, is working on cultured meat research. The concept dates back to the ERATO Takeuchi Bio-Fusion Project, which continued for approximately 6 years from 2010. At the time, cultured meat was highlighted as a possible application for cell-based manufacturing techniques.

Currently, Dr. Takeuchi is the R&D representative for the "Development of the production technology for next generation-meat using 3D tissue engineering techniques" in the "Sustainable Society" mission area of the Future Society Creation Project and aims to develop a sustainable resource-cycle society based on cultured meat (Fig. 3). Dr Takeuchi spoke of the significance of this research, "Not all meat can be produced by culture techniques alone. However, the food crisis has already become a major problem. Partially meeting the demand for edible meat using cultured meat will ensure consistent food delivery to as many people as possible."

Stacking sheets of muscle cells The world's first "cubed steak"

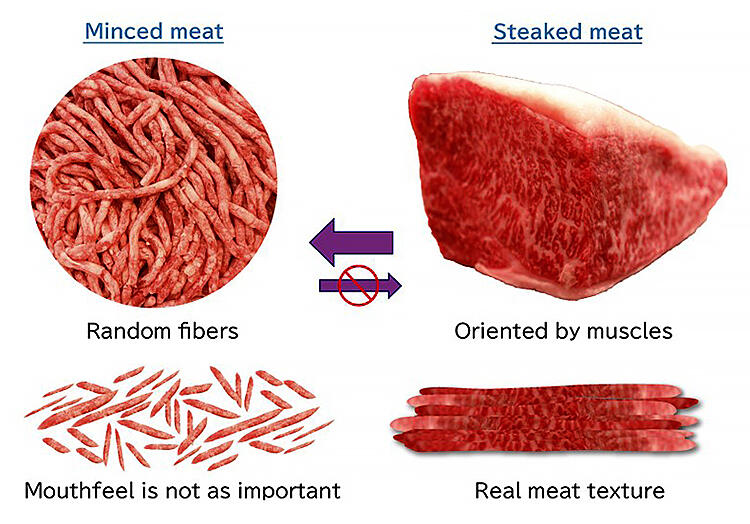

The predominant cultured meat produced by many companies is minced meat, which is an aggregate of muscle cells. However, Takeuchi and colleagues aimed at creating a steak-like meat with three-dimensional muscle fiber structures, blood vessels, connective tissues, and other tissues similar to those of natural muscles. "The technical hurdles are high, but if we can achieve it, we believe we can provide delicious meat with the same texture and flavor as real meat, which people will want to eat because it is delicious."

To produce cultured meat, first, cells that serve as the base for growth are collected from cattle. The resulting cells undergo repeated cell divisions and increase in number in the culture medium. In general cell culture, cells grow in different directions on a two-dimensional plane and do not have a three-dimensional structure. In the case of minced meat, which is formed by collecting a large amount of muscle cells that have been amplified in this manner, cheap mass production is possible using the current technology.

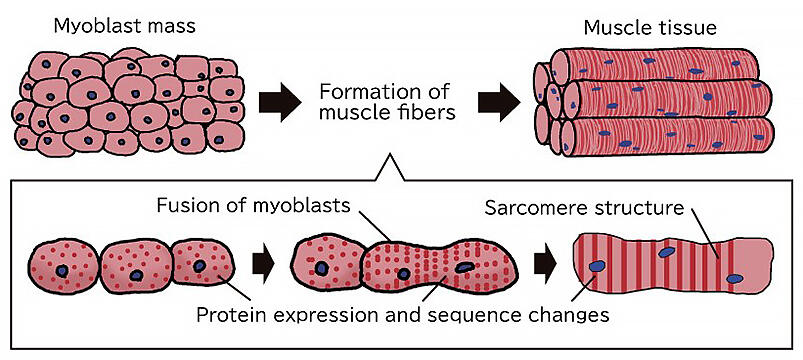

However, real muscle has a structure in which elongated muscle fibers that are aligned in one direction are bundled, and this structure produces the texture and mouthfeel of meat (Fig. 4). To reproduce the same structure as real meat, technology for culturing muscle fibers in the same direction and the maturation technology that fuses cells to form the striped "sarcomere structure" that is characteristic of muscle tissue are also required (Fig. 5). Dr. Takeuchi explains, "We decided to develop a new cell culture technology because it is not possible to make ideal meat cultures using existing technologies alone".

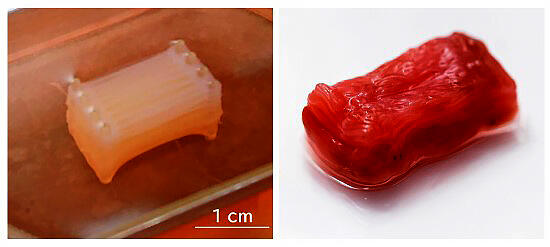

When Dr. Takeuchi determined that vitamin C stimulated maturation, he attempted to culture bovine myoblasts in a mold with an elongated slit form using collagen gel (Fig. 6). This succeeded in creating a sarcomere-like structure. "Myoblasts can fuse with each other and grow. I thought that if you add slits, you could create a long and narrow space, such that growth could only occur in the long axis direction. We hit the bullseye with this," he says with a smile. The researchers created a sheet-shaped module to arrange the muscle fibers in this manner and succeeded in preparing the world's first cubed steak of cultured meat by stacking these sheets (Fig. 7).

Cheap and animal free: seeking a sustainable manufacturing method

For Dr. Takeuchi, who is aiming to prepare around 100 g of steak meat, this result was only a steppingstone. "To be similar to real meat, it is necessary to develop thicker and larger muscle fibers as well as tissues, such as fat and blood vessels. There are still further issues to consider for establishing a sustainable manufacturing method."

One of the challenges currently being addressed is the preparation of culture fluids. Cultures contain nutrients to increase the cell size and serum components, including growth factors that stimulate cell division. Nutrients are relatively inexpensive; however, serum components are very expensive as they are obtained from fetal bovine blood. "In the future, we are looking for a culture solution that can replace serum components such that we can continuously produce cultured meat using animal-free methods. If this can be realized, the production cost will be reduced." he explains.

The second challenge is the efficiency of myocyte proliferation. As not all cultured cells differentiate into myocytes, Dr. Takeuchi and his group are investigating the conditions that facilitate efficient myocyte proliferation and differentiation into these target cells. "Individuality in behavior is also observed, such as cells that do not differentiate into myocytes but are prone to proliferation, and vice versa," as mentioned by Dr. Takeuchi. Although it is not possible to determine culture conditions that allow mass-production at a factory all at once, Dr. Takeuchi is attempting to determine a solution during the period that he is involved with the project.

The third issue is the supply of nutrients within the three-dimensional structure. Thus far, for two-dimensional culturing, cells are immersed in the culture medium and all the cells are sufficiently nourished. However, when the structure grows three-dimensionally, nutrients do not reach the cells that are not in contact with the culture medium, leading to cell death. "It is now possible to create a three-dimensional structure by stacking sheets. However, to increase the size of the product, a blood vessel-like structure must be developed to supply nutrients during culture." By facing these challenges, Dr. Takeuchi's expertise in tissue engineering is being suitably utilized.

The fourth challenge is maturation. As confirmed in prior research, vitamin C promotes the maturation of bovine muscle cells, while electrical stimulation of muscle fibers can also promote maturation. However, it is not easy to reproduce processes common in living organisms in the laboratory. The optimal timing and quantity of vitamin C and electrical stimulation must be determined from an infinite set of combinations. However, if these problems are solved, it will be possible to efficiently produce cultured meat along with generation of useful knowledge for regenerative medicine, tissue engineering, biochemistry, and other fields.

Safety assurances and "Deliciousness" must be considered

In Singapore, chicken nuggets made from cultured meat have been on the market for 20 years, but Dr. Takeuchi himself has not yet tasted the cultured meat he has created. "I've always wanted to try it but haven't yet," he says regrettably. If meat prepared in a laboratory is actually eaten by the researchers who prepared it, then it is considered an experiment using humans.

Therefore, it becomes necessary to apply to the research ethics committee of the university and obtain due approval. "Because of the unprecedented situation, we have had to set our own standards; however, after repeated discussions with the project members, we have finally reached the stage where we can complete the application. "I want to make it possible for researchers to taste samples in the near future," he resolves. Careful consideration is given to ensuring the safety and security of cultured meat not only within the university but also domestically across Japan. Reagents used in culture are approved for medical use but are not distributed as foodstuffs. For example, for the culture solution, it is necessary to select a material that has already been treated as food or meets the requirements of the "food additive list" determined by the government.

From the perspective of strengthening food security, including meat production, the Ministry of Agriculture, Forestry, and Fisheries launched the Food Tech Public-Private Council in 2020. While considering the existing livestock industry, the council has identified issues related to the distribution of cultured meat and is conducting discussions aimed at enacting legislation. "We are considering the naming on food labels. In fact, considering competition from overseas, some would prefer rushing these products to the market as soon as possible. However, because this is a new technology, stakeholder gathering and careful discussion considering multiple perspectives is necessary," says Takeuchi as he watches the transition calmly.

In addition to safety, consumers are quite concerned with taste. A well-established evaluation of "deliciousness" is "sensory evaluation," which evaluates taste and quality based on human senses. However, evaluation is a special task that requires skill and delicate senses. It would not be practical to train such assessors solely for cultured meat. There are also ranking systems, such as A1-A5, for animal beef, but this outlines the amount of meat that can be obtained from one animal and the degree of marbling, and hence, is not suitable for evaluating deliciousness.

Dr. Takeuchi, who aims to develop real meat, is reconsidering the definition of meat deliciousness. There have also been opportunities to learn from experts, but a clear solution has not yet been obtained. "I think it is difficult to evaluate deliciousness because there are multiple factors involved, but it would be easy to understand if it could be expressed numerically. It is safer to have an objective evaluation when eating," he proposes, in a typical engineer-like manner. If a taste sensor could be developed, it could be applied to existing foods.

From "denial" to acceptance by providing information: Japanese brands are world-class

Even if it was possible to produce palatable and safe cultured meats, these would not always be purchased by consumers. Rejection of emerging technologies is not uncommon, and can be quite severe for foodstuffs, especially genetically modified crops. However, there are many cases where new food technologies have seamlessly blended into our lives, such as frozen food. To face this issue Dr. Takeuchi, with Nissin Foods Holdings, which is conducting joint research, and Associate Professor Aiko Hibino of Hirosaki University are continuing to survey the public's attitude toward cultured meat.

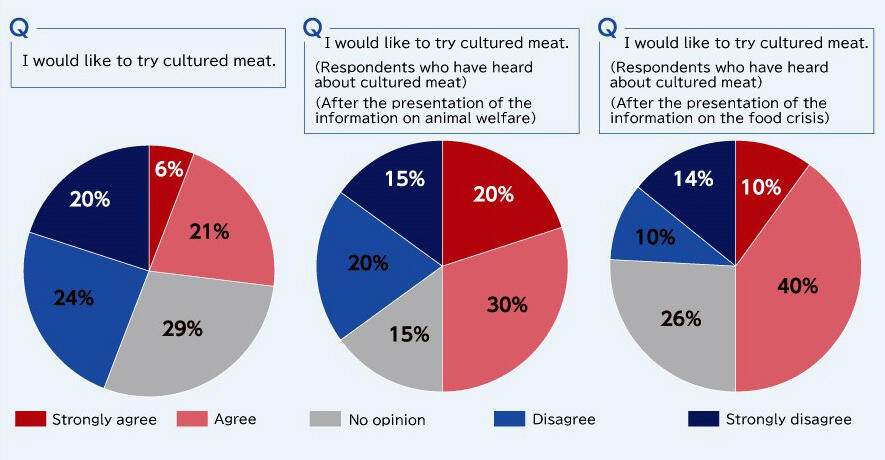

In 2019, when Dr. Takeuchi first succeeded in creating cubed steak-sized cultured meat, he conducted a questionnaire survey of 2,000 people (Fig. 8). The results indicated that 27% of people would eat cultured meat, compared to 44% who would not. Following the questionnaire, Dr. Takeuchi explained that it may be this technology that leads to the solution of the food crisis and contributes to improvement of animal welfare. Then, the respondents were asked again if they would eat cultured meat, with 50% responding affirmatively.

The survey results suggest that even those unreceptive to cultured meat may be accepting if made aware of the importance of this technology and its potential to initiate changes. "The survey results highlighted the importance of dialogue with the general public. In 2019, majority of people were not particularly interested in cultured meat. I felt that cultured meat would be accepted if we could disseminate information that could impact people," says Takeuchi.

Taking advantage of this knowledge, Takeuchi worked on a collaborative project with Associate Professor Akiko Sato of the Joshibi University of Art and Design. Utilizing the sensibilities of Joshibi students, cards that convey information on cultured meat were created (Fig. 9). "Everyone was concerned with conveying information about cultured meat in an easy-to-understand manner. I even had the chance to provide some of the words on the Karuta cards, which was fun," he says with a smile. In addition, study groups and symposiums with companies and related organizations are also being conduction, and Dr. Takeuchi feels that the awareness and attention on cultured meat is steadily increasing.

Regenerative medicine and three-dimensional tissue engineering are fields characterized by Japanese excellence. This is accompanied by the culture of Japanese cuisine and craftsmanship that has been cultivated over many years. "I think that Japanese-brand cultured meat will be well accepted worldwide. I want to make use of Japanese advantages to create a new industry," he says. The project has just begun. Understanding the people and the support of the country are also indispensable factors. "Let's work together to create cultured meat that is kind to the environment, animals, and humans," says Takeuchi with vigor.