Palm oil, squeezed from the fruit of the oil palm, is the most widely produced plant oil in the world. Palm oil and the fruit husks discarded in the production process can be used as biomass fuel. However, the spread of pests and diseases, soil degradation, and greenhouse gas emissions caused by neglecting old trees that have reached the end of their useful life are becoming serious problems in palm plantations. Dr. Akihiko Kosugi, a project leader in the Biological Resources and Post-harvest Division at the Japan International Research Center for Agricultural Sciences (JIRCAS), is working with the Malaysian government and oil palm plantations to rethink the palm oil industry and create a sustainable system in which both the environment and the economy circulate, by bringing together the technologies of Japanese companies for "innovative biomass."

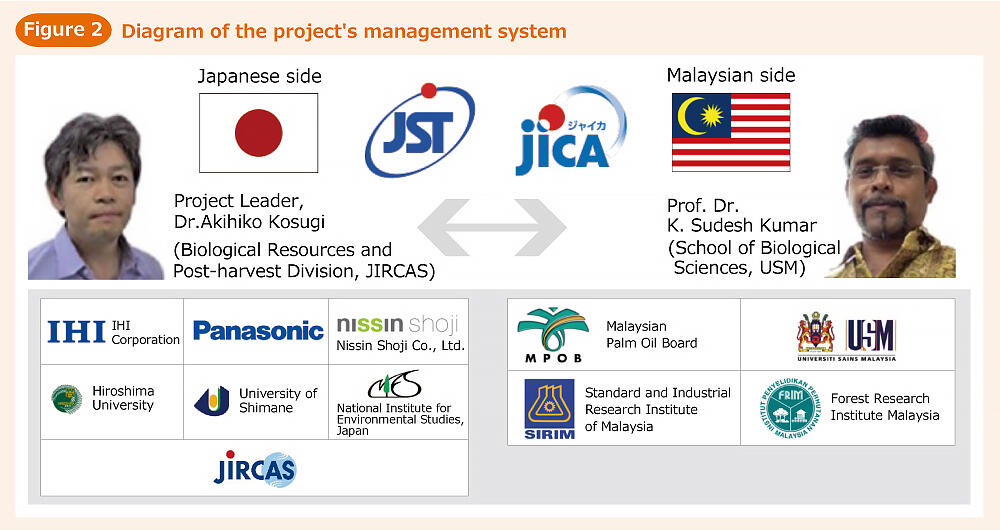

Project Leader, Biological Resources and Post-harvest Division, Japan International Research Center for Agricultural Sciences (JIRCAS); Principal Investigator since 2018 for the Science and Technology Research Partnership for Sustainable Development program (SATREPS).

Masaharu Yamashita

Chief Examiner, Equipment Design Group, Basic Designs Department, Carbon Solutions SBU Technology Center, Resources, Energy, & Environment Business Area, IHI Corporation; Sub-leader since 2018 for SATREPS Research Project 2

Old trees left unattended when replanting and pathogens and waste become problems

Oil palm trees only grow in tropical regions near the equator. The palm tree produces large clusters of fruit, weighing about 30 kilograms each, which are then pressed to produce palm oil. Palm oil is used in about half of all food and daily necessities, including in confectionery and soap. The advantage of palm oil is that it is tasteless, odorless, and easy to process for use in a wide variety of products. Furthermore, palm oil yields more oil per unit area than other types of oil, eight times more than soybean oil and five times more than rapeseed oil.

Approximately 50% of the world's palm oil is produced in Indonesia and 30% in Malaysia. In recent years, however, the palm oil industry has come under intense criticism from international environmental groups. The main reasons are because tropical rainforests are being cut down to expand highly profitable oil palm plantations, destroying the ecosystems, and because plantation workers are forced to perform hard labor for low wages. As pointed out by Dr. Akihiko Kosugi, project leader at JIRCAS, "Palm oil is a very important oil. If we try to make an alternative oil, then it will lead to further land development and further consumption of fertilizer and water. It is not that palm oil is bad, but the way it is produced is problematic."

First, there are problems associated with its characteristics as a plant. Oil palm trees need to be replanted because their fruit yield declines after 25 years or so. There are no facilities or places to dispose of the trunks, which are 10 meters high and weigh approximately 1 ton. Old oil palm trunks (OPTs) that are cut, sliced, and left in place are swarmed by termites, insects, fungi, and other soil pathogens, which can cause newly replanted oil palm trees to have poor growth or to wither and die.

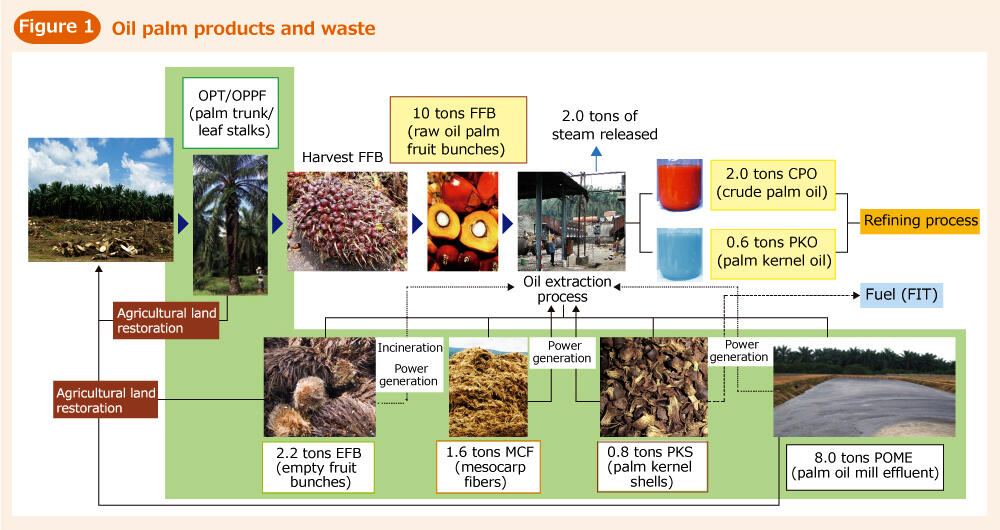

Second, the decomposition of abandoned OPTs produces 1.3 tons of methane and carbon dioxide (CO2) greenhouse gases per OPT. Because the trunks are approximately 70 to 80% water they cannot be used as wood in their original state, and if they are burned they generate a large amount of smoke, which causes smoke pollution. Third, after the oil is squeezed out at the oil extraction mills, a large amount of waste is left behind, such as empty fruit bunches and fruit husks (Fig. 1). The only way to deal with this waste is to dispose of it or incinerate it. From 10 tons of fruit, 2.6 tons of palm oil is produced, which leaves several times that amount of agricultural waste.

(Source: "Study of the Abra Palm Farm Problem," edited by Hideki Hayashida, Koyo Shobo Corporation)

Meanwhile, although the Malaysian government is aware of the problems, it is reluctant to regulate the practice of leaving OPTs on the plantations when the trees are replanted. Dr. Kosugi stated that, "If this situation continues, the palm oil industry itself will cease to exist. We wondered if we could restructure the entire industry into a sustainable form by utilizing all the waste from OPT and oil extraction as a biomass resource." Together with Universiti Sains Malaysia (USM) and the Malaysian government, and jointly operated by JST and the Japan International Cooperation Agency (JICA), Dr. Kosugi launched the "Sustainable Replantation of Oil Palm by Adding Value to Oil Palm Trunk through Scientific and Technological Innovation" project through SATREPS.

Decompositional bacteria inhibiting plant growth leads to the desire to change a century-old farming method

Dr. Kosugi first visited an oil palm plantation in Malaysia in 2004. He recalls, "At a factory that made plywood boards from OPTs, I was surprised to see the OPTs being turned into thin boards, like daikon radish slices, while being sprayed with water." What was also shocking to Dr. Kosugi, who specializes in microorganisms that break down cellulose, was that the cut edges of the OPTs that had been left for only a few days were covered in black mold. "I knew instinctively that something was happening!"

Subsequent analysis revealed that the OPTs contained sap with about 10% sugar content. Explaining the resource value of OPTs, he said that, "OPTs look like giant sugarcane, but they are an agricultural waste product. The sugar from it can be an excellent resource that doesn't compete with food. This was a great discovery." Immediately, Dr. Kosugi announced that ethanol, lactic acid, biopolymers, and other products could be fermented and produced from the sap extracted from OPTs.

Recently, he has been conducting experiments to measure the amount of methane gas produced when the trunks and leaves are left to decompose, and to compare plant growth between soil containing OPTs and soil without OPTs. As a result, he found that soil containing OPTs spreads mold and inhibits plant growth. This is because mold and bacteria, which feed on OPTs, preferentially grow in the soil, depriving the soil of fertilizer components such as nitrogen, phosphorus, and magnesium.

However, on Malaysian farms it is believed that, if left alone, OPTs will return to the soil and become fertilizer. "In fact, quite the opposite is true, but it is not easy to change a farming practice that has been in place for more than a century. Whenever there is poor growth, such as discolored leaves or decreased fruit yields, the addition of more fertilizer has become the norm. We couldn't convince these farmers just by showing them the data," he says, explaining the difficulty of changing their minds.

Additionally, numerous companies have tried to use and industrialize OPTs, but none have succeeded. "Stable and inexpensive procurement of OPTs is essential for recycling. Moreover, as long as there are no economically successful cases, no one wants to take the risk," said Dr. Kosugi. In order to get the involvement of farmers and oil extraction mills, who are not highly motivated to use OPT and biomass, it was necessary for the project to take the lead until they could first set a successful example.

Bringing Together Technologies from SMEs Nationwide ― Joint Research Involving Major Companies

In Japan, Masaharu Yamashita, a Manager at IHI, was focusing on using OPT biomass. Mr. Yamashita had envisioned a biomass power generation business in which high-sugar sap would be converted into methane gas, and the residue from pressing the OPTs would be used as fuel pellets. The two met at a biomass expo exhibition in 2013, and they joined forces and began joint research on OPTs.

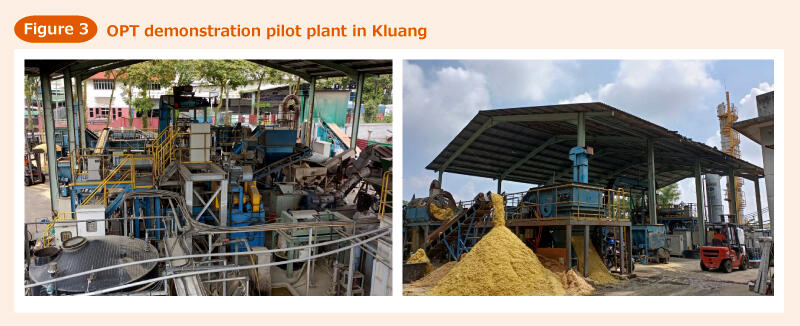

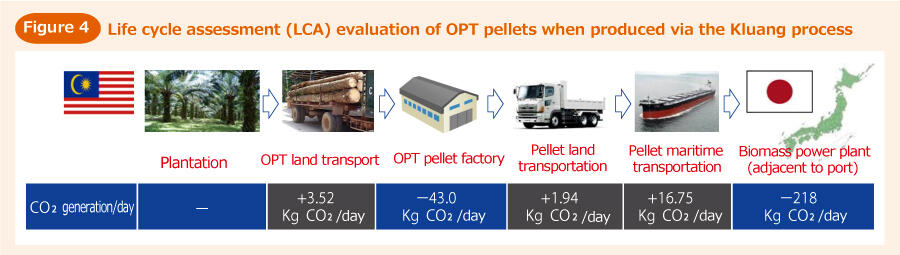

In 2017, IHI led the construction of an OPT demonstration pilot plant to produce fuel pellets from OPTs in Kluang, southern Malaysia (Fig. 3). The goal of the plant is to demonstrate the production of OPT pellets. Currently, under the management of SATREPS, the plant has now completed a zero-emissions process that offsets the amount of greenhouse gas emissions from removing the OPTs from farms, processing them, and then transporting the pellets, and this is done by using methane gas extracted from OPT cleaning effluent to generate electricity and capture heat, which is then used in the pellet manufacturing process (Fig. 4).

CO2 emissions from Malaysian plantation to OPT transport, pellet processing, and export to Japan. The pellets can be used with negative emissions even when brought to Japanese ports. This requires proper treatment of OPT processing effluent (conversion to energy).

The plant also demonstrated a full-scale "biomass zero emission process" that enables the recovery of fertilizer used for growing oil palm from the effluent, returning it to the plantations as liquid fertilizer. This facility was named the "Kluang process" after the city where it was installed. The process has made great strides after being adopted by SATREPS in 2018. At the time, Dr. Kosugi was greatly helped by Mr. Yamashita's enthusiasm and engineering expertise.

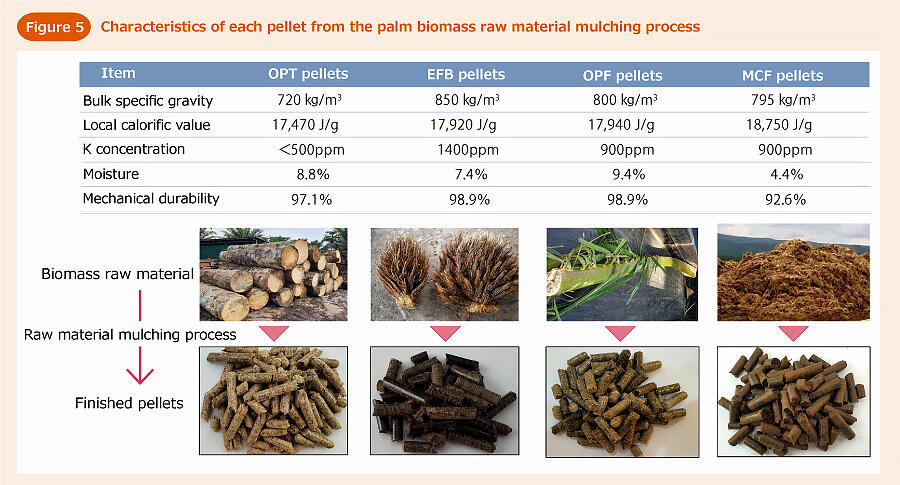

The "raw material mulching," in which empty fruit bunches, fruit fibers, and oil palm branches and leaves are also used as raw materials, is another result of Mr. Yamashita's coordinating skills (Fig. 5).

In the raw material mulching process, the same process as for OPTs can produce pellets of the same quality from empty fruit bunches, branches and leaves, and fibers.

By breaking up and softening the plant fibers with a blasting machine, the raw materials other than OPTs can also be processed via the same process. This blasting device is manufactured by Mori Machinery Corporation (Akaiwa City, Okayama Prefecture). "Actually, the Kluang process is based on coordinating the excellent technologies of Japanese small and medium-sized enterprises (SMEs). The two of us went around to each of these SME companies and asked for their cooperation, saying, 'We can save the earth with the technology you have!'" Dr. Kosugi said with a smile.

The use of OPTs is also supported by the innovative technologies of other SME companies throughout Japan, such as Masuko Sangyo Co., Ltd. (Kawaguchi City, Saitama Prefecture), with its palm fiber grinding technology, and Toyo Screen Kogyo Co., Ltd. (Ikoma County, Nara Prefecture), with its technology that can instantly separate solids and liquids. They are also aiming to package the Kluang process, which brings together these technologies, and connect it to infrastructure exports. Dr. Kosugi is hopeful, saying "I would be happy if we could realize 'innovative biomass,' a solution to global-scale problems through the advanced technological capabilities of innovative Japanese enterprises that cannot be imitated in other countries."

Panasonic Housing Solutions (hereinafter "Panasonic"), which will participate in the second year of the SATREPS project, is another company that was considering collaboration in advance. In 2021, SATREPS developed a technology for selectively extracting long fibers from OPTs, and Panasonic put wood boards made from this technology into actual use. In 2022, the "Palm Loop" brand was launched, which began manufacturing and selling OPT furniture through furniture manufacturers such as Yamada Denki (formerly Otsuka Kagu) and TOKYO interior (Fig. 6). The most important thing to remember is that the use of OPTs for timber will fix the CO2 absorbed by the forest for decades. In addition, the use of OPTs as a substitute for tropical forests will greatly contribute to forest conservation.

Recycled boards created from oil palm (left) and the press release from when Panasonic introduced "Palm Loop" into the furniture industry (right). As a "new material that can replace lumber," it is expected to help protect the environment and create local employment.

Applied research is also being conducted on sap. When Mr. Yamashita touched the sap, he noticed that his hands were moistened by it. "When I investigated the sap components, I found that it had an extremely strong antioxidant effect. It was an accidental discovery, but now we are working with a team in Malaysia to develop a cosmetic product called OPT Cosmetics." Mr. Yamashita emphasizes the appeal of joint research, saying that the fact that the range of OPT utilization is being expanded by involving other companies and people in this way is a major achievement of this professional project.

Model Demonstration in Sarawak State: Expansion to all of Malaysia

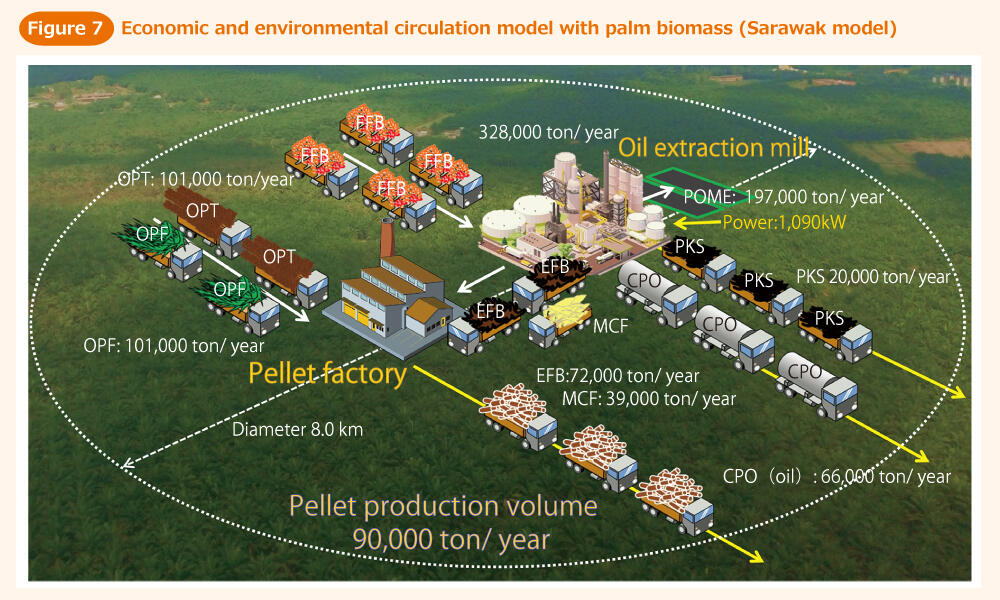

Going forward, Dr. Kosugi and his colleagues hope to implement the Kluang process, which succeeded in demonstration experiments, in Malaysia and throughout Indonesia. Palm farms have problems with OPTs and fertilizer purchase costs, while oil extraction mills have problems with empty fruit bunches and effluent treatment. And the main concern of both parties is profit. In exchange for zeroing out OPT procurement costs from farms, the demonstration experiment also accepts waste matter (such as empty fruit bunches) and effluent from the oil extraction mills and makes pellets via the raw material mulching process. This system would stabilize biomass procurement and increase profits, while at the same time enabling environmental measures to be taken. If such a system were established, it would create a virtuous cycle that simultaneously solves both environmental and economic problems. Sarawak state is a pioneer in this regard. In Sarawak state, the farms and oil extraction mills are often integrated. When planning for a plant with an annual pellet production of 100,000 tons, only using OPTs as the feedstock gives a collection area with a 50 km radius. On the other hand, the Sarawak model, which is premised on the introduction of a raw material mulching process, can sufficiently supply raw materials from within a radius of approx. 4km in which the fruits are harvested daily by trucks (Fig. 7). Currently, a social experiment is underway between Nissin Shoji (Minato-ku, Tokyo) and a company that manages a palm plantation and oil mill in Sarawak state.

A stable and inexpensive procurement model will create both environmental and economic incentives to solve the problems of oil palm plantations.

Dr. Kosugi would also like to encourage the Malaysian government to certify only biomass products that are produced through sustainable processes. OPTs are already one of the biomass types approved for Japan's renewable energy feed-in tariff (FIT). However, the project wants to institutionalize the use of palm biomass in such a way that greenhouse gas reductions will not be ignored for economic reasons. If a sustainability certification system specifically for palm biomass is established in the future, it must help to dispel the bad image of the palm industry.

Through this project, Dr. Kosugi feels that, in order to take research to the level of social implementation, it is important not only to talk about big ideas, but also to start from a realistic place and show what can really be done. Looking ahead to the future, he says that, "I would like to continue to pursue both academic research and social implementation." It will not be long before the use of OPTs as a next-generation biomass technology that saves the entire palm industry will be realized throughout Malaysia.

(Text: Midori Oguma, Photo: Hideki Ishihara)