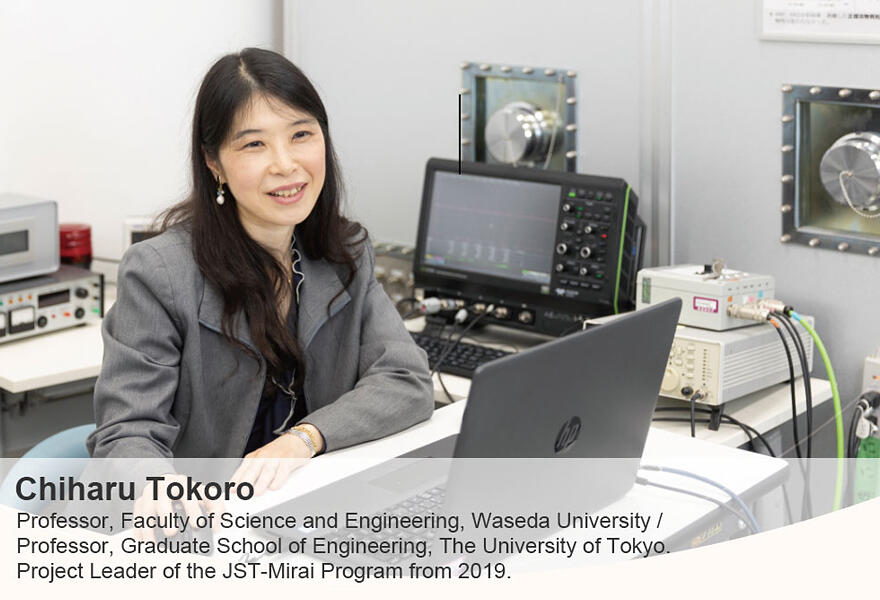

With an eye towards the realization of carbon neutrality, secondary batteries and electric vehicles (EVs) will be introduced, and vehicles utilizing lithium-ion batteries (LIBs) and composite materials are expected to dominate the market, leading to expectations for an increased demand for specific resources such as rare metals. When this occurs, technologies enabling efficient resource circulation will become even more important. Professor Chiharu Tokoro of the Faculty of Science and Engineering at Waseda University is developing separation technologies capable of extracting valuable resources from used products manufactured using such composite materials, enabling their recovery at low load and cost.

A novel electric pulse method developed to expand the circular economy

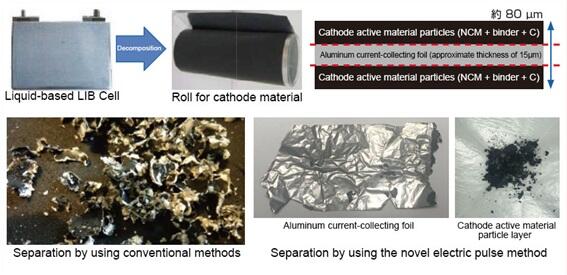

A sample in which the cathode active material of a LIB is treated with a momentary high voltage at both ends results in a loud "bang" sound and causes black particles to detach from the cathode active material and the aluminum foil they were attached to. This technology, called the "novel electric pulse method," achieves this separation. The black particles of the cathode active material consist of the oxides of highly useful elements, such as nickel and cobalt, which can be reused.

Tokoro is leading this research and development (R&D). The current recycling process involves crushing, grinding, and sorting waste materials and extracting valuable substances such as gold for reuse using chemical processing. However, this approach allows for the recycling of only economically valuable elements, limiting the scope of resource circulation. "That's why I felt the need for more precise and innovative separation technologies," explained Tokoro, reflecting on the motivation behind the development.

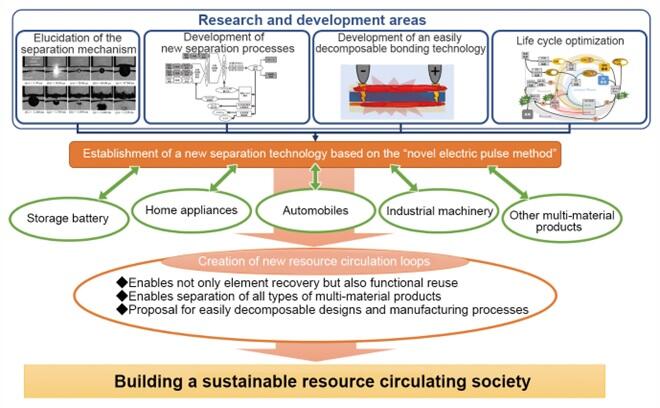

Tokoro is aiming to expand toward a circular economy model (Figure 1). In addition to the so-called 3R's of "Reuse," "Reduce," and "Recycle," the circular economy model aims to continuously use resources in a circular manner by reusing waste as raw materials. Instead of disposing natural resources and generating waste, this approach focuses on using the material to its full extent over its lifetime without creating waste.

Figure 1: Roadmap for the JST-Mirai Program (Professor Tokoro's mission).

There are no efficient separation technologies currently available to enable the recycling of LIBs. The cathode active materials can be extracted from LIBs by physically sorting the materials after incineration and pulverization or by decomposing, cleaning, and then pulverizing the materials. Both methods have a significant environmental load and incur costs (Figure 2).

Figure 2: Selective separation of LIB cathode materials.

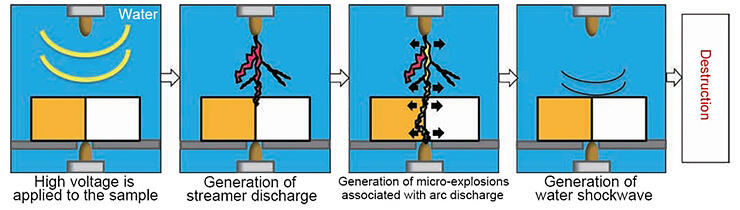

The existing separation technologies have two main aspects: workability and selectivity. Mechanical crushing and grinding exhibit a high work efficiency but cannot extract only the necessary materials. The manual sorting method has a lower efficiency, but it offers a higher level of selectivity. The conventional electrical pulse method lies between these two methods. Here, a sample is placed between electrodes fixed in water, and selective destruction of the interface is achieved by applying a discharge-induced shockwave. The novel electrical pulse method, as compared to the conventional method, improves both the workability and selectivity, and innovatively reduces carbon dioxide (CO2) emissions as well.

Tokoro used the JST-Mirai Program to advance the R&D of this method. She applied for and was selected for the Prioritized Theme focusing on "Innovation in manufacturing for new process of sustainable resource recycle," starting the R&D of "Establishment of integrated circular manufacturing system by product lifecycle management and innovative dismantling technology development." Tokoro has been conducting exploratory accelerated research since November 2017 and has been engaged in full-scale research towards social implementation since 2019.

Troublesome multi-materialization — Considered an easily decomposable design

Tokoro decided to apply for the JST-Mirai Program with the expectation that it would raise awareness among manufacturing organizations about the importance of resource circulation to ultimately trigger a transformation in design concepts. "There is currently a demand in the industrial sector for high functionality and low cost, which has led to the increasing multi-materialization of products. However, resource circulation becomes challenging owing to the increased energy and cost required for the separation process," explained Tokoro. Existing processes that are further intensified by multi-materialization progress are undesirable from both the environmental and economic perspectives.

At the same time, Tokoro has perceived a change in the attitude of industry in response to the current demands. "With the need to achieve the SDGs, carbon neutrality, and to establish a circular economy, companies are beginning to develop an awareness of resource circulation. The importance of manufacturing products that are easily decomposable is being recognized," she said. This change in awareness is also reflected in the term "Inverse manufacturing." This term means designing and manufacturing products based on the flow of "recovery, decomposition, sorting, and reuse" of used products. This is precisely the "easily decomposable design and manufacturing process" that she aims to achieve. Companies have started to perceive production activities not only from the perspective of the "environment" and "economy" but also from the perspective of "society."

Tokoro aims not only to develop processing technical advancements but also to contribute to the reconsideration of design and manufacturing concepts within industry and the creation of new resource circulation loops. This intention is evident in the establishment of research structures involving not only universities across the country but also major companies. To achieve this, evaluations from non-technology perspectives are indispensable. She revealed her commitment to building the infrastructure, stating, "It is essential to collaborate with experts who can simulate and evaluate processes and systems using new technologies throughout their lifecycle."

Achieving fine control through trial and error: Clarifying the mechanism through a series of hardships

Professor Tokoro emphasized three perspectives, namely, "environment," "economy," and "society," in the development of technology for resource circulation. Building a circular economy requires technologies that reduce environmental load, are economically viable, and meet the demands of each era's society. She added, "If we develop a separation technology that achieves harmony between the environment, economy, and society, it is possible to extract high-function materials from what is currently being discarded."

So, how did Tokoro formulate the novel electric pulse method?

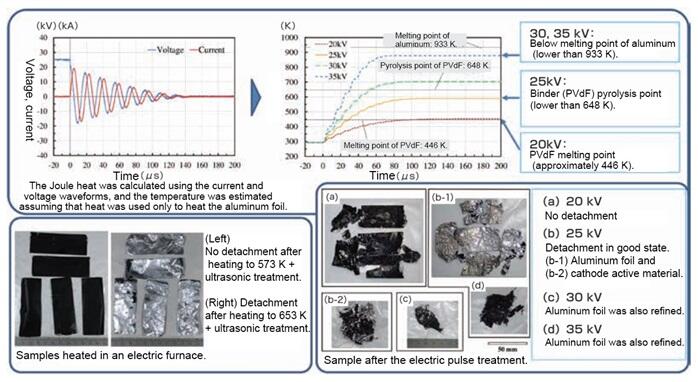

From the beginning, she had social issues in mind. She sought a method to efficiently extract only the necessary resources from products that could pose challenges to resource circulation, including LIBs. Consequently, Tokoro developed the novel electric pulse method, in which high voltage is applied to induce various phenomena such as impact, heating, and reactions to achieve separation. Despite the high voltage, the energy usage is relatively low due to the momentary current flow (Figure 3).

Figure 3: Conventional electric pulse method.

However, the separation accuracy of the conventional electric pulse method was low because the method mainly used generated shockwaves. It was difficult to completely separate the cathode active material of LIBs from the Al foil at their interface. Precise separation requires more precise control of the discharge paths, current/voltage waveforms, and frequency of the applied voltage, as compared to the conventional method. In other words, if phenomena other than shocks can be used, selective separation at high-performance interfaces can also be achieved.

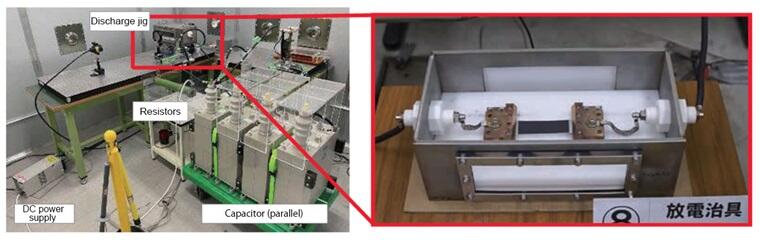

In terms of the application conditions, the objects to be separated, such as the aluminum foil and cathode active materials, should be conductive materials and have different electrical characteristics. Concurrently, the novel electric pulse method, unlike the conventional method, also has the advantage of being applicable not only in water but also in air. The potential of the novel electric pulse method was confirmed through trial and error at the laboratory level (Figure 4 and Figure 5). "We theoretically knew that separation would occur at the interface if we could finely control the operating conditions. I was fortunate to encounter that phenomenon at an early stage," reflected Tokoro.

Figure 4: Experimental apparatus for material separation using the novel electric pulse method.

Figure 5: Material separation by using the novel electric pulse method.

However, it was a series of hardships from there. First, there was a hurdle of scientifically explaining the phenomenon of the detachment of the cathode active material. To clarify this mechanism, full-scale research involved procuring analytical instruments and conducting tasks such as capturing the detachment phenomenon using high-speed and thermography cameras. At the moment, it is clear that the adhesive on the interface is decomposed by the Joule heat generated by the electrical current, causing the aluminum foil to expand under the influence of the electromagnetic field's Lorentz force, thereby facilitating detachment.

Clarification of the mechanism seemed to have been progressing smoothly. However, Tokoro then encountered a barrier where the detachment phenomenon was not stable for various types of LIBs. She stated, "To reproduce the detachment phenomenon for any type of LIB, we first need to form hypotheses and conduct experiments, and then quantitatively analyze the results to contribute to the understanding of this mechanism," looking ahead with this approach in mind.

Changing awareness in companies and scaling up the equipment

Another challenge is the response to multi-materialization,which involves considering the applicability to easily decomposable EV bodies. To pursue further weight-reductions in EV bodies, various materials, such as carbon fiber-reinforced plastic (CFRP), are used in the appropriate locations of the EV body. The feasibility of using the novel electrical pulse method as a technique to separate these dissimilar materials from each other or to selectively extract carbon fibers from CFRP is being considered.

One particular difficulty was negotiating with companies for the supply of experimental materials. Possessing information about the scientific form in which certain substances exist facilitates material examination. However, even with confidentiality agreements in place, there were instances where product information disclosure was denied due to confidentiality concerns. Tokoro expressed concerns, saying, "In such a situation, separation technology cannot thrive."

Nevertheless, as she pointed out, the awareness of industry's responsibility towards resource circulation has significantly changed. She placed hope in the future, stating, "Now is the last chance to initiate efforts towards achieving inverse manufacturing and a circular economy." It has been approximately three and a half years since full-scale research began. The novel electric pulse method has shown some progress, although there are still challenges in elucidating the mechanism.

At the laboratory level, the method has been established as a separation technique to the extent that quantitative judgments can be made regarding its suitability for separating various substances. Tokoro explained, "Currently, from the perspective of promoting designs that are easier to decompose, we can make qualitative proposals that such a design is required when considering the application of this technology." In the final year of the JST-Mirai Program, Tokoro aims to scale up the experimental setup in collaboration with companies for social implementation. The experimental apparatus for LIB material separation includes an LIB transport section and space for the recovery of the cathode active material, edging it closer to a fully functional separation system.

She emphasized the importance of understanding social needs rather than solely relying on research seeds. "It is crucial to accurately understand which parts of the supply chain pose bottlenecks for separation technology and the related processes before embarking on R&D. We must be careful not to misjudge the initial problem setting," she stated. By combining the novel electric pulse method with various separation techniques, Tokoro's efforts towards building the circular economy will continue.

(Text: Shunsuke Mogi, Photography: Hideki Ishihara)