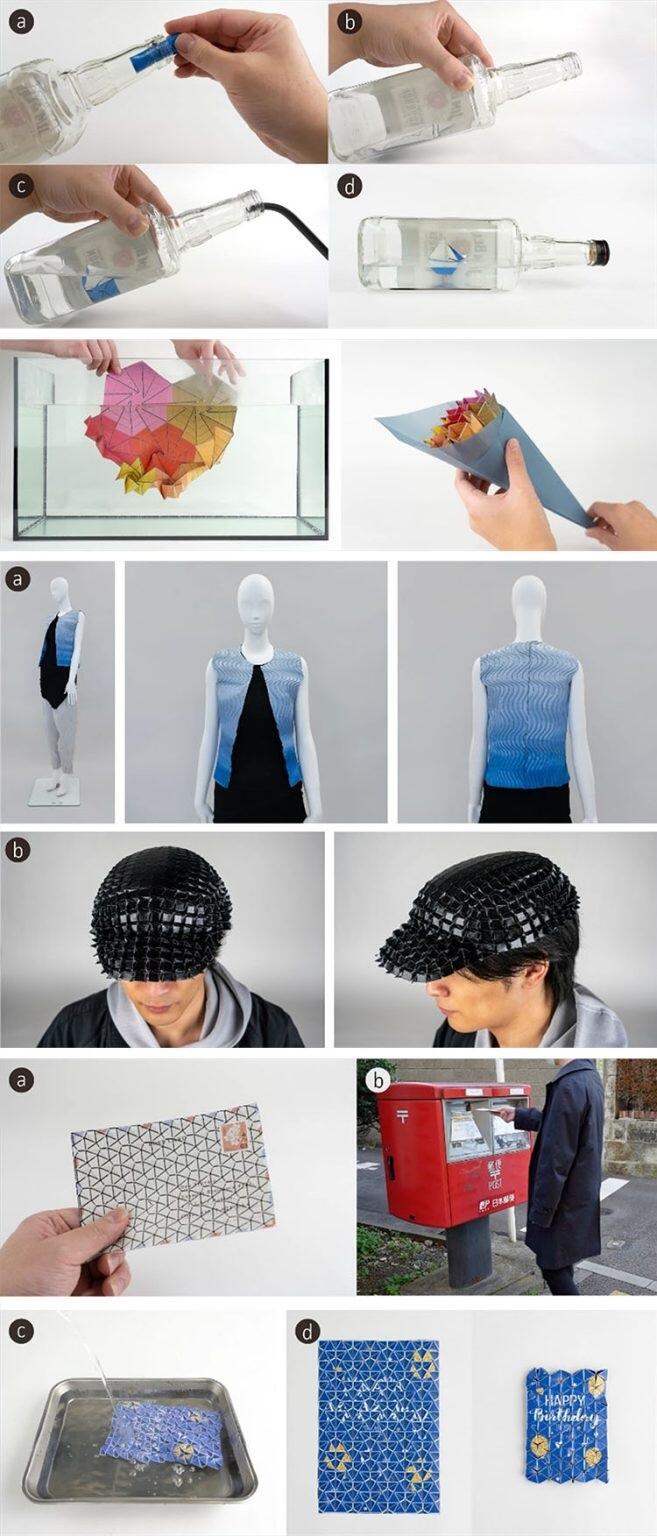

The art of folding paper is a cherished and traditional part of Japanese culture and is recognized globally by the name 'origami.' A skilled person can quickly and easily fold an 'origami crane,' which is synonymous with origami. However, it may take up to 10 hours to precisely fold a rabbit, for example. To save time and effort, a technology has been developed that can create an origami sheet and automatically fold it into a 3D object with up to 100,000 folds and tens of thousands of faces within seconds to minutes. This is achieved by applying hot water to the sheet with mountain and valley fold patterns created and printed on it. This technology is expected to be used in a wide range of fields, including the apparel, medical, and space industries.

Provided by Project Assistant Professor Koya Narumi at the University of Tokyo

Origami's 'self-folding' feature resolved the problems associated with 3D printers

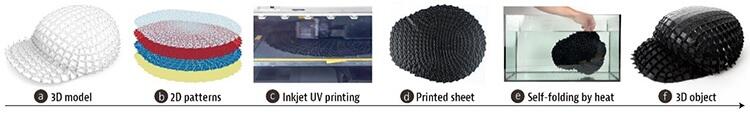

The manufacturing of 3D objects has become more accessible with the development of 3D printers. However, certain challenges, including size limitations imposed by the printer, the generation of waste material in the form of 'support structures' required to maintain the structure and prevent collapse during printing, and difficulties in storage and transportation when multiple finished items are produced, still remain. Project Assistant Professor Koya Narumi, who studies Design Engineering at the School of Engineering of the University of Tokyo, and his colleagues believed that they could address these problems by developing origami sheets that can be stored in two dimensions, such as paper, and that exhibit 'self-folding,' whereby the material itself transforms when needed.

They decided to use commercially available UV printers employed in factories and workshops to enhance future versatility. The printer uses ink that dries under UV light, making it possible to produce origami sheets in a shorter time than with ordinary ink.

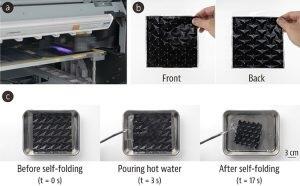

Heat-shrinkable sheets, namely, transparent polyolefin films or polyester cloths, which are readily available, were used as the printing material. The origami sheet is printed with patterns of valley and mountain folds. Subsequently, when heat is applied, the sheet shrinks, and it folds automatically.

Provided by Narumi

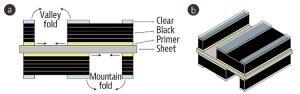

The valley and mountain folds of origami are determined by whether ink is applied onto the front or back of the heat-shrinkable sheet. The inked area prevents the sheet from shrinking, and the paper folds in the non-inked direction. When heated to 70−100 ℃, which is sufficient to not affect the hardness of the ink layer, the heat-shrinkable sheet shrinks by approximately 5%. Therefore, when a complete 180°fold is desired, a gap of approximately 1 mm is left in the folded area.

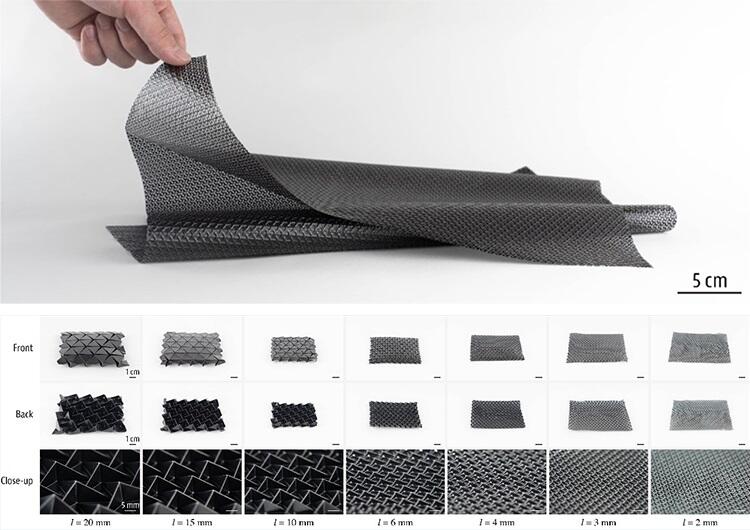

In this research, five layers of black ink were applied, resulting in a finished origami sheet with a thickness approximately equal to that of three sheets of paper (i.e., less than 0.3 mm).

Provided by Narumi

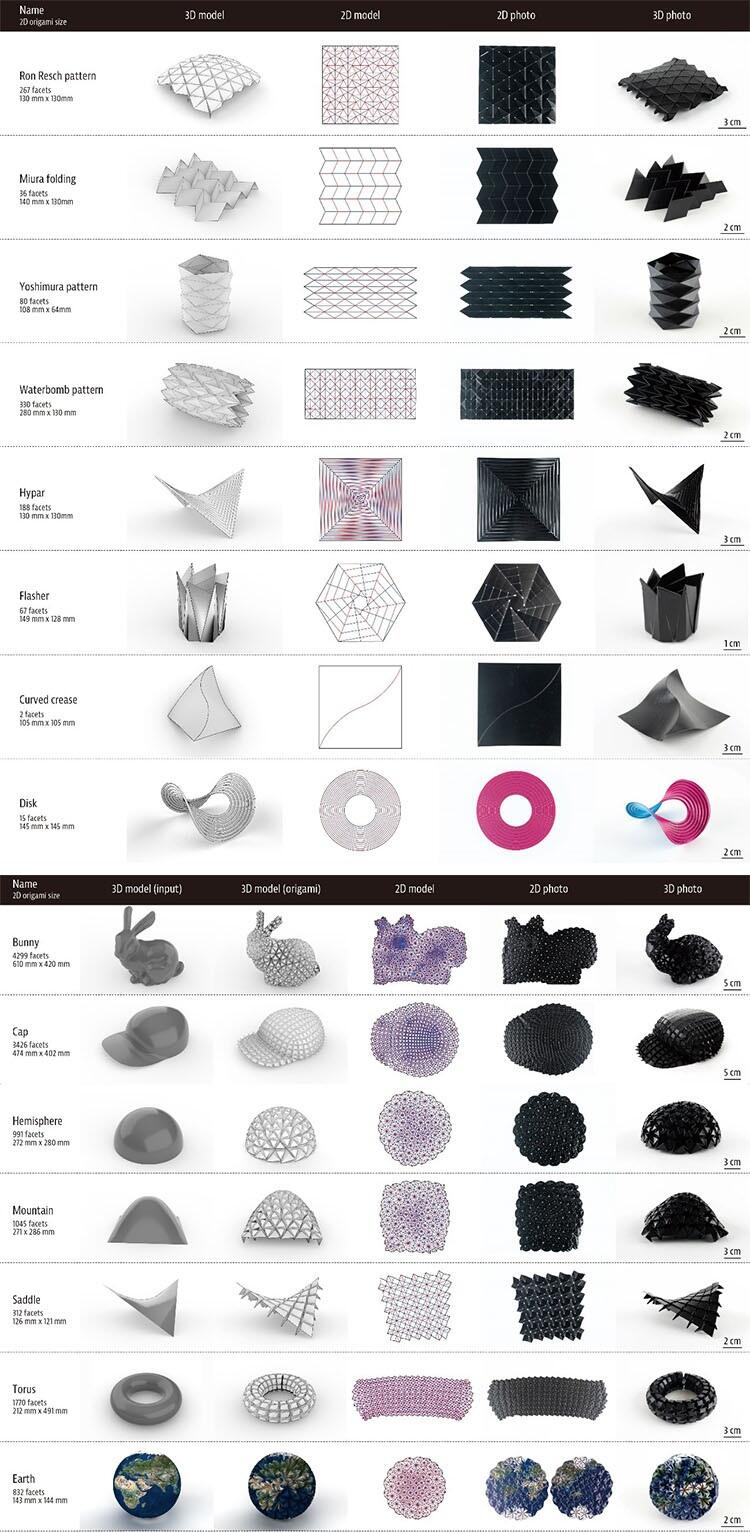

Three mm per side: Realizing a resolution 1,200 times higher than the conventional one millimeter per side

In previous research, the maximum number of fold lines and surfaces that could be automatically folded in an origami structure was approximately 100. The newly developed origami sheet can fold lines as fine as 3 mm per side because patterns are printed with a resolution of 600 × 600 dpi (dpi represents the number of dots lined up per inch). The resulting resolution is 1,200 times higher than that achieved in prior research, enabling the creation of an origami sheet with a maximum of over 100,000 folds and tens of thousands of surfaces within seconds to minutes by simply applying hot water.

Provided by Narumi

Extensions of the origami design software (Origamizer and Crane) developed thus far by the research group have also enabled the conversion of designed origami into printing patterns and calculation of printing patterns for folding origami from arbitrary polyhedra.

This research was conducted in collaboration with Miyagi University and other organizations, with support from the Japan Science and Technology Agency (JST) and was published in the journal ACM Transactions on Graphics on July 26, 2023. They also presented this study at an international conference on computer graphics held in Los Angeles, California, USA, from August 6 to 10.

Provided by Narumi

Commercialization being considered with two companies

I had the opportunity of holding an origami sheet that had just been produced in the laboratory. It had a similar appearance and texture to the Nori seaweed used in sushi rolls. Further, it shrinks upon heating, similar to Nori seaweed. When the product is compared to seaweed, the level of appreciation seems to slightly diminish. However, Narumi stated, "I can't mention specific industries or company names, but two companies are already considering commercializing the product." He mentioned that there is growing interest in the origami sheets from various companies.

Provided by Narumi

The technology of self-folding origami has the potential to benefit various industries, including the apparel industry, which extensively uses pleats for clothing, the medical industry, where it can be utilized for structures that expand inside the body like stents, and the space industry, where compactness is essential for launching and transporting items such as solar panels and satellite wings. It can be valuable for both large- and small-scale productions. I believe that this technology has the potential to capture the interest of people both domestically and internationally, establishing itself as a part of 'Cool Japan,' Japan's brand strategy that aims to disseminate Japan's attractiveness and allure to the world.

Journal Information

Publication: ACM Transactions on Graphics

Title: Inkjet 4D Print: Self-folding Tessellated Origami Objects by Inkjet UV Printing

DOI: 10.1145/3592409

(NAGASAKI Midoriko / Science Portal Editorial Office)

Original article was provided by the Science Portal and has been translated by Science Japan.