Provided by NMRI

In the final installment of 'Exploring megascience,' we introduce the 400m Towing Tank of the National Maritime Research Institute (NMRI) at the National Institute of Maritime, Port and Aviation Technology (MPAT), which straddles the cities of Mitaka and Chofu in Tokyo. As an island nation surrounded by the sea, maritime transportation and marine resource utilization are extremely important for Japan. The results of tests conducted in this water tank, which boasts one of the largest scales in the world, demonstrate improved ship performance and are reflected in the establishment of international rules.

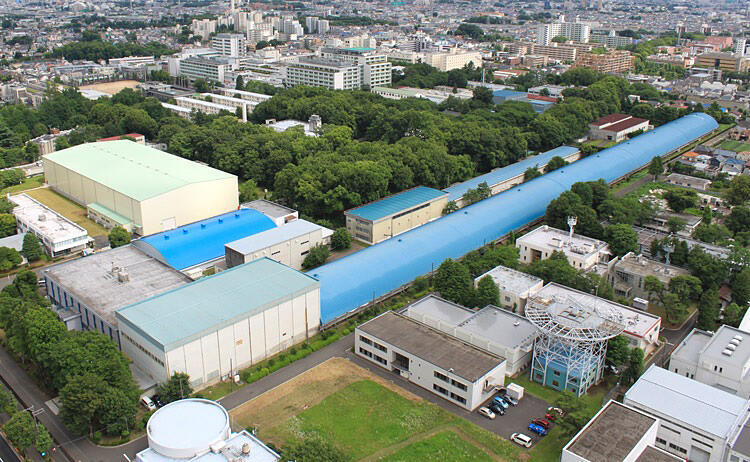

An above-ground tunnel in the middle of a residential area?

Approximately three kilometers south of JR Mitaka Station, on the border with Chofu City, lies a very unique building in the middle of a quiet residential area. Although its width from east to west is only slightly around 20 meters, its length from north to south is approximately 20 times the width, creating an elongated tunnel-like appearance above the ground. No loud noises or odors emanate from this building, and it is often difficult to judge, at first glance, the nature of activities within this mysterious building.

This building, in fact, houses a long test water tank that is 400 meters long, 18 meters wide and eight meters deep. This is the aforementioned 400m Towing Tank. This water tank was first established in 1966 to conduct tests to assess and confirm the performance of ships close to the actual scale. Even after more than 50 years since its establishment, this water tank, as one of the world's largest test water tanks, is still used for conducting various tests and continues to contribute to the development of technology.

Looking back in history, the roots of NMRI date back to 1916, when the Ship Equipment Inspection Station under the Ministry of Telecommunication and Transport was first established. For more than 100 years from now, efforts to improve maritime technology have been prioritized in our country. Unlike the other facilities featured so far in 'Exploring megascience,' this facility is located in a residential area and supports cutting-edge marine technology in harmony with the surrounding environment.

'Air-lubrication method,' which covers a ship's bottom surface with air bubbles to reduce drag

An experiment utilizing this scale was an 'air-lubrication-method' test conducted by towing a 50-meter-long model ship, the largest of its kind in the world. In the air-lubrication method, the bottom of a ship is covered with air bubbles emitted from the hull to reduce the drag on the hull, and the underlying principle has been known since the 19th century. In the 1990s, scientific research was conducted using models; however, its effectiveness could not be entirely confirmed using ship models with lengths of four to 10 meters, thus hindering practical applications.

In response to this, an experiment was conducted using a model ship with a size similar to that of a real ship. Consequently, Director Masaru Tsujimoto of the Fluids Engineering & Hull Design Department at NMRI explained, "This test quantified the effectiveness of the air-lubrication method on actual vessels, and we were able to understand mechanisms for efficient air blowing. Ships built with this technology have reduced energy consumption by approximately 6%."

Model ship running at over 50 kilometers per hour

So, what does this 'air-lubrication-method' experiment look like? In this experiment, rails are installed on both sides of a long water tank. A towing carriage runs along these rails, pulling a scaled-down model of an actual ship. ''Rail maintenance is also important for highly accurate testing. With a distance of 400 meters, a height difference of approximately two millimeters exists between the end and center of the rail; hence, the height is adjusted to match the water surface level. Notably, the rails used are the same as those used on the Shinkansen bullet train,'' stated Tsujimoto.

The author took a test ride in the towing carriage. The model ship splashes through water, creating bubbles and moving along a straight line through the long, narrow channel. The maximum speed is 54 kilometers per hour, approximately the same as that of a car on a regular road. The towing carriage has no outer wall; so, without support, a person will likely be blown away.

Just when the author thought it was picking up speed, the towing carriage slowed down. At a high speed, the towing carriage will only require a few tens of seconds to cover the distance of 400 meters. Of course, a single test is not adequate to obtain sufficient data; so, after a while, the model ship reaching the goal is returned to the starting point and subjected to the test several times with different parameters.

Recently, investigations have been undertaken to test the effectiveness of the air-lubrication method when barnacles and other organisms are attached to the hull. Investigators have been installing cone-shaped protrusions resembling barnacles at regular intervals along the bottom of the model ship to determine the resistance to the hull. By reproducing the marine environment in this way, as precisely as possible, practical technologies are being developed.

Live streaming of the test status for industrial applications

The 400m Towing Tank also contributes to international rule establishment. For example, when regulations were established to reduce greenhouse gas emissions from ships, a method was developed to precisely estimate the force exerted by waves in an actual marine environment by utilizing a wave generator installed in a water tank. With this, the relationship between the hull shape and increased resistance in waves could be modeled and reflected in international rules.

"It is very important to set international rules, and for new technologies, the standards of the first country to implement them will be reflected. Japan's strength lies in improving the performance of vessels in actual water environments; thus, being able to incorporate this into the rules is a significant achievement," said Tsujimoto.

The 'NMRI Cloud,' started by the Institute in 2021, incorporates a 'water tank online witnessing system' that provides live streaming of the test conditions in the 400m Towing Tank. In the shipbuilding industry, data can be used and compared using paid apps. The chat function can be used to transmit and receive data files and confirm with the test administrator(s).

Until now, engineers from shipyards and other facilities have been required to be present onsite during water tank tests; however, this system allows the engineers to remotely witness these experiments, simplifying the processes of data checking and contacting for re-tests. This has also saved time and money required for business trips and created the benefit of quicker decision-making for each stakeholder.

Various water tanks for different environments

NMRI has several other test tanks in addition to the 400m Towing Tank. The 'Actual Sea Model Basin' has a total of 382 high-precision wave-making machines in its whole circumference and can reproduce any complex wave occurred on the sea surface. "This water tank's wave-making ability is the best in the world. For instance, by reproducing the process through which a ship is overturned by a wave, the difference in the timing of encountering a wave, the change in lowering the ship's center of gravity, and measures to prevent overturning can be studied," explained Tsujimoto.

Provided by NMRI

Other facilities include a Large Cavitation Tunnel for testing the cavitation of propellers mounted onto the hull (a phenomenon in which cavities form on the surfaces of the blades, degrading their performance), a 35-meter-Deep Sea Basin, and a Pulsating Wind Tunnel with Water Tank for testing under strong winds to facilitate testing in various environments.

Cutting-edge research through open innovation

Previously, larger vessels were mandatory; however, since the oil shocks of the 1970s, energy conservation has gained more importance, while in recent years, reducing environmental impact has emerged as an important theme. "For example, if a large container ship transports cargo from Japan to the U.S., the cost of fuel is approximately 100 million yen per trip," said Tsujimoto. Therefore, improving fuel efficiency not only saves energy but also improves the competitiveness of the domestic industry.

In addition to this, numerous studies are being conducted using advanced technologies, including artificial-intelligence-based logistics efficiency and digitalization of shipyards. Experimental data from the 400m Towing Tank also contribute to technological development in various ways, including verifications of fuel efficiency to reduce CO2 and other greenhouse gas emissions from ships and evaluations of the optimal ship shape and propeller design.

"In the future, cutting-edge research must be conducted through open innovation, in collaboration with external parties," said Tsujimoto. The development of advanced ammonia combustion technology, which is being jointly advanced with engine manufacturers and shipbuilding companies, could be a representative initiative.

Cheap heavy oil has long been used to power ships; however, the drawback of its use is that it emits large amounts of greenhouse gases such as CO2. Therefore, the exploration of technologies to run ships using ammonia or hydrogen as an energy source is underway. Mitigating global warming is an imminent concern affecting the entire world, and revolutionary changes are likely to be implemented in the shipbuilding industry in the near future.

Despite this, the importance of a facility to verify maritime technology on a scale close to that of actual practice will remain unchanged. Tsujimoto shared, "The unit cost of fuel is high for energy sources other than heavy oil; thus, companies must consider ways to improve efficiency to the maximum possible extent. We expect demand for the 400m Towing Tank to increase even more."

Upgrade to a 'Super-400m Towing Tank'

Plans to upgrade the 400m Towing Tank to a 'Super-400m Towing Tank' are also underway. "In recent years, advances in measurement technologies have enabled optical measurements of the water flow around a vessel's hull. Therefore, we are planning to convert this into a water tank that can be properly evaluated. This should allow more sophisticated simulations of fluids and more rapid technological developments," explained Tsujimoto. In addition, an offshore water tank is planned to be set up as a field where measurements can be made on an actual scale.

In late June, the process of draining the 400m Towing Tank was commenced. Such draining activity has been undertaken for the first time since the facility was completed. The facility has been in use for many years and is scheduled to undergo a comprehensive overhaul and complete maintenance to realize the super 400m Towing Tank. The importance of maritime technology has always been the same. The large experimental water tank will continue to evolve so that the oceans and vessels of the future are safer and more abundant.

Original article was provided by the Science Portal and has been translated by Science Japan.